Aquafighter® Revolution offers fuel stations reduced fuel losses, optimized tank maintenance & environmental advantages

DieselCare AS is developer & manufacturer of Aquafighter® Fuel Technology, DieselCare Skimmer® and DieselCare Chinook® Vent Filter. Forward-thinking in the Norwegian tradition, DieselCare creates impactful advancements for the fueling industry.

Aquafighter® Revolution has proven to recover millions of liters of waste fuel, increase fuel quality, and has redefined modern fuel tank maintenance.

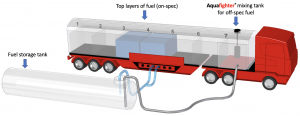

KONGSVINGER, NORWAY, March 21, 2022 /EINPresswire.com/ -- Aquafighter® Revolution is making it possible for fuel stations to eliminate fuel losses and to maintain fuel tanks more effectively and more efficiently. The Aquafighter® Revolution process utilizes the Aquafighter® Fuel Technology to restore waste fuel and high water-content diesel back into better-than-spec fuel as well as to prevent fuel tanks from accumulating water and developing sludge.

"Aquafighter Revolution is primarily about restoring off-spec fuel and waste diesel back into retail-quality fuel. Normally fuel companies write-off a significant amount of fuel every year that is deemed unrecoverable. With the Revolution system we can normally restore 80 to 90% of this fuel, and that is where the most money is for the oil companies." Per Jahnsrud, CEO of DieselCare AS and inventor of Aquafighter®.

Along with losing the fuel which is expensive in itself, fuel companies also must pay to dispose of the flammable waste. The Aquafighter® Revolution gives fuel stations the double benefit of saving the fuel losses and eliminating the costs associated with hazardous disposal. Another added benefit is that the environmental impact is reduced by conserving fuel and protecting the environment from excess hazardous waste.

"As fuel prices around the world are reaching new highs, the financial gains that we achieve for our customers in Scandinavia are now available for every oil company and fuel station in the world. We aim to give these companies significant financial profits as well as supporting environmental managers with their environmental goals." Steve Schultz of DieselCare/Aquafighter.

The Aquafighter® Revolution works by combining 1 micron particle filtration along with mixing Aquafighter® Technology with the high water content fuel to remove up to 100% of free water and up to 99.998% of bound & emulsified water while also removing up to 100% of heavy & large particles as well as up to 95% of micro-particles smaller than one micron. This process creates fuel with water content as low as 21ppm, without chemical additives or masking agents, while also creating a tank regimen that prevents the fuel tank from developing sludge and reduces serious water-related problems over the lifetime of the tank.

"Most tanks take less than 1 hour, making our Aquafighter Revolution system an ideal combination of cost, time and results for fuel-quality management & fuel tank maintenance. The results of Aquafighter Revolution are superior in every way when compared to fuel polishing and fuel additives with the icing on the cake being that Aquafighter is also non-toxic, non-corrosive and creates less material waste." Steve Schultz.

Along with restoring bad fuel to high-purity, the other core utilization for the Aquafighter® Revolution system is as a fuel management and tank maintenance regimen to control both fuel & tanks over time. With periodic use of the Revolution system, fuel operators can assure that their fuel remains in control and that their tanks do not develop sludge and other significant water-related tank problems, for the lifetime of the operation.

"We welcome the opportunity to consult with any oil company, fuel station or service provider on how they can implement Aquafighter® Revolution. In the short time that we have been utilizing Aquafighter for fuel companies in Norway, we have recovered more than 4,000,000 liters of diesel that otherwise would have gone to waste. Combining the cost of that fuel with the cost of disposing that fuel, we have saved our customers more than $5,000,000 US dollars. There are many more millions to save in every country." Per Jahnsrud.

Aquafighter® Revolution is also ideal for diesel generators, agriculture fuel tanks, fuel logistics, fuel storage, mining operations, fuel depots, marine fueling and diesel fleets. DieselCare AS is available to answer questions from customers and media on WhatsApp at +47 484 07 240, by phone at +1 407-564-2411 and by email at sales@aquafighter.com.

###

Steve Schultz

DieselCare AS/Aquafighter

+1 407-564-2411

sales@aquafighter.com

Aquafighter® Revolution Demonstration:

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.