Veelo Technologies Helping to Keep Aircraft Rotor Blades Out of the Oven

With their patented heating blanket solutions, Veelo Technologies helps composite rotor blade manufacturers and repair facilities keep blades out of the oven.

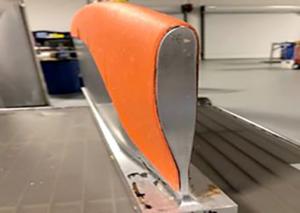

CINCINNATI, OH, UNITED STATES, February 23, 2021 /EINPresswire.com/ -- With their patented and innovative heating blanket solutions, Veelo Technologies helps composite rotor blade manufacturers and repair facilities keep blades out of the oven (OoO). Veelo’s heating blankets can be tailored for use in debulking and bonding applications and can be used in-situ, eliminating the need to transport long and bulky rotor blades to an oven. Eliminating that transportation step helps improve build and repair rates while reducing scrap.

Due to their uniquely flexible and pliable design, Veelo’s heating blankets are highly drapable and provide uniform heating coverage across the large and geometrically complex surface areas found on rotor blades. Veelo heating blankets easily accommodate custom shapes and large tools with minimal or few bridging issues. They are durable and damage resistant and are offered in an optional FKM-based heater system for high performance and material compatibility.

Veelo heating blankets are controlled by the VeeloHEAT Controller, a cost-effective solution capable of controlling systems that can be adapted to the end-use application with 16 or more output channels. The digital IoT controller can store data and receive updates locally or via the cloud and is highly customizable.

According to Mr. Joe Sprengard, Jr, President and CEO at Veelo, “Our VeeloHEAT solution is currently used by the aerospace composites industry to bond and repair multi-million-dollar composite aerostructures. We are helping them accelerate adhesive cure, perform faster composite repairs, and improve the debulk processes. For rotor blades specifically, the net-shape draping that occurs with our blankets can help a manufacturer or repair facility realize substantial savings and improvement in build and repair rates. We provide an effective alternative to taking these blades to the oven.”

About Veelo Technologies

Veelo Technologies, a General Nano company, is an innovation company that develops advanced materials and manufacturing solutions for the fast-growing aerospace and defense composites industry, as well as for medical, battery, and electric vehicle applications. With headquarters in Cincinnati, Ohio, the company’s core competencies include chemistry, materials science, custom formulations, scaled manufacturing, and systems and application engineering.

Veelo Technologies’ advanced material solutions include electrically conductive materials that produce lightning strike protection and EMI shielding; lightweight heating solutions that enable out-of-autoclave (OoA), and out-of-oven (OoO) composite processing; and non-metallic, next-generation de-icing solutions for composite air vehicles.

The company’s team of scientists and engineers work side-by-side with technologists at the Department of Defense and global aerospace and defense companies to develop next-generation advanced materials.

Ms. Shasta Haddad

Veelo Technologies

+1 513-378-1904

email us here

Visit us on social media:

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.