Mastercam Users Cut Inspection Time 40% with Human-AI Metrology Integration

The Complete Scan-Probe-Verify Workflow—In One System. ReverseEngineering.com eliminates the "middleware tax" and puts engineers back in command.

LA JOLLA , CA, UNITED STATES, December 23, 2025 /EINPresswire.com/ -- FOR IMMEDIATE RELEASEMastercam Users Cut Inspection Time 40% with Human-AI Metrology Integration

The Complete Scan-Probe-Verify Workflow—In One System. ReverseEngineering.com eliminates the "middleware tax" and puts engineers back in command.

LA JOLLA, Calif., Dec. 22, 2025 — ReverseEngineering.com today launched its Mastercam 2026 add-in, delivering native support for FARO® Quantum X and Hexagon Romer Absolute® measuring arms while eliminating expensive standalone inspection software that costs $15,000+ per seat.

For the first time, engineers can execute the entire Scan-Probe-Verify quality control cycle without leaving Mastercam—cutting inspection setup time by up to 40%.

"The best manufacturing happens when human expertise and intelligent tools work hand in hand," said Braxton Carter, CEO of ReverseEngineering.com. "We've built a system where AI clears the path—finding features, calculating geometry, streaming data—so engineers can focus on making the critical metrology decisions that ensure quality and drive innovation."

How Scan-Probe-Verify Works

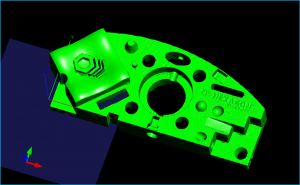

SCAN: Import E57 LiDAR point clouds or stream live laser scanner data directly into CAD. AI recognizes part geometry and suggests measurement strategies.

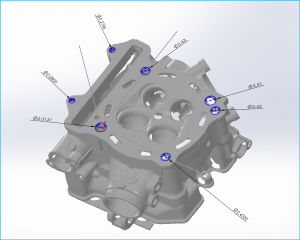

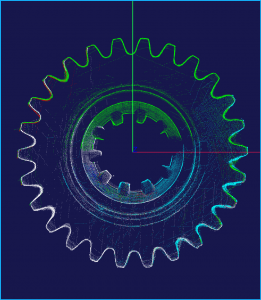

PROBE: Use FARO or Hexagon arms to capture critical dimensions with AI-assisted feature recognition. The system identifies cylinders, planes, cones, and complex surfaces—engineers approve or refine based on their expertise.

VERIFY: Compare probed data against CAD models in real-time. Engineers set tolerance bands, establish acceptance criteria, and make final quality decisions. Full GD&T support ensures compliance with engineering drawings.

No file exports. No software switching. No middleware extracting value while adding friction.

"Scan-Probe-Verify used to require three different software packages and countless file conversions," Carter said. "Now it happens in one place, with AI handling connections and engineers handling decisions that matter."

The Human-AI Partnership

The Mastercam 2026 add-in represents a new paradigm: AI handles the busywork while engineers handle the expertise.

AI recognizes geometric features, calculates best-fit diameters and cylinders, and streams live measurement data into CAD toolpaths. Engineers set tolerance criteria, make acceptance decisions, apply metrology best practices, and maintain quality standards.

This delivers measurable results—40% faster inspection setup—while keeping engineers in command. Every measurement is transparent, every decision traceable, every workflow optimized for human intelligence augmented by computational speed.

"We had a customer spending two days setting up inspection routines for complex aerospace castings," Carter explained. "Now they complete the same work in half a day. They've eliminated tedious setup and can focus on the nuanced metrology decisions that matter for flight-critical components."

Technical Capabilities

Universal hardware support:

FARO Quantum X and Max series arms

Hexagon Romer Absolute 7-axis and 8-axis systems

FAROBlu™ and Hexagon AS1/RS6 laser scanners

Keyence

Microscibe

Revware

OPEN SOURCE API Connect your CMM / Scanner to Mastrecam

Complete Scan-Probe-Verify workflow:

Native E57 LiDAR support for terrestrial laser scanning

Direct point cloud viewing and feature extraction

Live laser scanner data streaming to CAD

Real-time CAD comparison with full GD&T support

Human-AI collaboration:

AI-assisted feature recognition with engineer oversight

Automated best-fit calculation for cylinders, cones, spheres

Full transparency—every AI suggestion can be reviewed or overridden

Complete audit trail for ISO 9001 and AS9100 compliance

Workflow transformation:

Zero file translation or format conversion

Real-time data streaming from hardware to CAD

Up to 40% reduction in inspection setup time

Availability and Free Trial

The Mastercam 2026 add-in is available now through ReverseEngineering.com and authorized resellers worldwide.

Manufacturers can test the complete Scan-Probe-Verify workflow with a 30-day free trial.

→ Request your trial: www.reverseengineering.com/mastercam2026

About ReverseEngineering.com

Since 1995, ReverseEngineering.com has developed direct-to-CAD metrology solutions that eliminate software bottlenecks. Headquartered in La Jolla, California, the company builds specialized add-ins connecting portable CMMs, laser trackers, and 3D scanners to leading engineering platforms, including Mastercam, SolidWorks, Fusion 360 , Ansys Discovery, Siemens NX , Solidedge , AutoCAD and Autodesk Inventor. Over 2,000 manufacturers worldwide rely on ReverseEngineering.com to accelerate quality control and reverse engineering while maintaining complete human oversight.

#

Media Contact:

Amanda Blake

Marketing Department

ReverseEngineering.com

Phone: (858) 488-5231

Email: MediaRelations@reverseengineering.com

Website: www.reverseengineering.com

Amanda Blake

ReverseEngineering.com

+1 858-488-5231

email us here

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

Mastercam Probe Scan Verify

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.