Aluminum Extrusion Die Cleaning with NuSoft

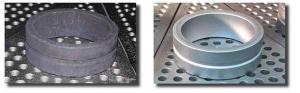

Blast Cleaning Aluminum Extrusion Dies using NuSoft Blast Media

PAINESVILLE, OHIO, USA, February 28, 2023 /EINPresswire.com/ -- Nu-Soft is a metallurgicaly enhanced, ultra-soft shotblast cleaning and polishing blast media, which works great for aluminum extrusion die cleaning.

The extreme operating conditions in the press can cause problems, like aluminium build up and subsequent wear or damage to the bearing face. This in turn, can lead to reduced capacity and delayed orders as a result of the bearing surface not being clean or smooth enough to keep the extrusion going.

The solution is to maintain the extrusion dies to a high standard with regular cleaning, inspections and corrections as required, an operation carried out by skilled, and often expensive, die correctors.

The first step in the cleaning, inspection and correction process is a caustic soda dip. This softens and removes heavy aluminium contamination, but smaller aluminium particles can remain along with discoloration from the heat and pressure of the extrusion process. The residual aluminium and discolouration makes die inspection extremely difficult.

Objective: Removal of dry contaminants such as heat treat scale, residual caustic soda, and aluminum particles from die surfaces leaving a thoroughly clean, smooth finish. Respect for die tolerances, edges, and dimensional integrity.

Solution: Nu-Soft blast media is specifically designed for the application of Aluminum Extrusion Die Cleaning

Features of Nu-Soft Shot:

- Extended die life

- Dramatic reduction in die polishing requirements

- Elimination of many die defects

- High productivity & full loads of dies can be cleaned in brief cycles

- Low energy requirements

- Low compressed air required

- Little manual labor,the operator must only load, turn over, and unload the dies as cleaning occurs automatically

- No appreciable machine wear because NuSoft is soft

- Repeatability : the same thorough, uniform cleaning every cycle, every die

- No die damage where edges are not rounded, tolerances are respected, and the resulting finish is smooth

- Low operating costs

- Full range of die sizes can be cleaned

- Safe and efficient, environmentally friendly & non-hazardous

- Among the softest shot blasting media for die cleaning (less than 20Rc)

- Economical = outlast other media by thousands of cycles

- Recyclable = less waste & reduced material handling cost

Not only is SoftShot safe to use on your product and in shotblast equipment, it is a non-hazardous material, and can be disposed of in the same manner as your standard SAE shot.

Art Koch

Unified Technologies

+1 440-897-5226

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.