New Lafarge Reports Suggest Lordstown Landfill’s Final Cap may be Failing

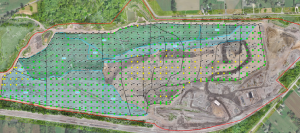

Lordstown Landfill's March 2022 surface scan report identified that 90% of the 2020 and 2021 capped areas are emitting toxic gases up to 20 ppb. Rotten egg odors occur at 10 ppb. Blue shaded areas are capped. Green and yellow dots are gas emission points.

Water is Soaking in, Toxic Gases are Oozing out

Modern landfills apply both clay and thick plastic sheeting as the critical final cap or seal. But demolition landfills in Ohio only require an 18 inch-thick clay cap. A cap is the barrier which stops precipitation from soaking into the landfill and keeps dangerous sulfide gases from escaping.

Landfill caps are cost effective as they dramatically reduce water infiltration which reduces the volume of waste-contact water or “leachate” which must be collected and treated. Lafarge pays the City of Warren’s sewage plant $0.03/gallon or up to $700,000/year for treatment.

Clay caps must meet Ohio EPA’s geotechnical specifications but even then are subject to erosion, desiccation and chemical attack. Steep landfill slopes increase the likelihood for erosion problems. Lafarge received a waiver to increase the regulatory maximum slope angle of 25% to 33%. The maneuver added four million cubic yards of waste space and millions in profits but increased the potential for long-term problems.

In 2015, Lafarge installed a cap on the north slope which quickly eroded and exposed rotting waste; a horrible rotten-egg stench engulfed the Village. 177 odor complaints led to a televised public meeting with angry citizens and the Ohio EPA. The slope was then re-capped at the cost of $600,000.

Lafarge, now Holcim US, is the parent company of the Lordstown Landfill. Since 2015, the Ohio EPA has issued the company 40 Notices of Violation, two consent orders, fines totaling $270,000 and cited more than 1,000 consent order violations. Dozens of violations have been documented in the past six months.

The operational, engineering and environmental violations include: accepting banned pulverized waste, illegally pumping groundwater, not covering waste, causing odor nuisances, exceeding design limits, discharging polluted water, poor stormwater controls and violating the toxic gas limits on residential properties.

The landfill’s 2022 license currently hangs in administrative limbo. Mark Schmidt, who worked for both the Ohio EPA and Lafarge, remarked “Apparently the Trumbull County Health Department is too embarrassed to approve the license and too dependent on Lafarge’s waste fees to deny it”. The health department has received more than $6 million from Lafarge.

If any landfill needs the highest quality cap, it is Lafarge’s. Why?

First, even acceptable demolition waste contains drywall which decomposes and creates poisonous gases such as hydrogen sulfide and carbon disulfide. But pulverized demolition contains billions of tiny particles for bacteria to feed upon and accelerates gas production. Demolition waste “cocktailed” with sewage sludge is worse. Lafarge has been cited for accepting pulverized waste multiple times including in October 2021.

Second, water is a key driver in the formation of noxious gases. Lafarge initially excavated the site 50 feet below the surrounding surface and cut through multiple groundwater tables. Groundwater rushed into the 1.3 million square foot pit. Although prohibited by Ohio EPA regulations, Lafarge surrounded the hole with pumps to keep the sidewalls from collapsing.

Lafarge kept pumping until the pit was filled with two million tons of out-of-state waste — but the inflow of water never stopped. During a 2015 Ohio EPA inspection, Lafarge was caught pumping 100,00 gallons/day of water contaminated with ammonia through a 400-foot firehose to a pond connected to Duck Creek. This extreme violation was an integral part of the 2016 consent order and penalties.

Third, infiltration creates leachate which is pumped to the City of Warren’s sewage treatment plant. Warren’s plant is currently at capacity and struggling to maintain compliance with its own EPA permits. As long as Lafarge continues to be the county’s largest wastewater generator, Warren will have difficulty approving other quality businesses which require a sewer tie-in.

Fourth, there is an Ohio EPA requirement for landfills to maintain a certain level of post-closure financial assurance. The financial estimates include assumptions that the cap will not fail and leachate quantities will diminish according to known industry projections.

If these assumptions for Lordstown prove faulty, and the landfill subsidiary is spun into bankruptcy oblivion to protect Holcim, the financial reserves may prove inadequate — particularly since massive groundwater inflow is permanent. Perpetual management costs could fall back on taxpayers and possibly Lafarge’s customers.

Fifth, the concentration of the shallow sulfide gases at Lordstown have been measured at an astounding 40,000,000 parts per billion (ppb) and are extremely corrosive and poisonous. The gases create sulfuric acid when combined with moisture and can easily denature soil. Black “veins” and “scabs” on the landfill surface indicate where soils have been destroyed. Only the modern high-density plastics are resistant to this level of chemical attack.

Several 2022 reports indicate the cap is not doing its job.

The Lordstown Landfill has capped approximately 70 acres or 60% of the active area since 2016. Water infiltration should be decreasing. However, Lafarge’s March 2022 report to Warren's sewage plant indicates the total volume of contaminated water has nearly doubled since 2017, rising from 91 million gallons to over 170 million gallons.

Additionally, Lafarge’s 2016 consent order requires monthly hydrogen sulfide scans across the entire landfill. Most scan points are now located on capped areas. Disturbingly, Lafarge’s March 15, 2022 scan report indicates over 90% of the capped areas installed in 2020 and 2021 are leaking toxic gas up to 20 ppb.

Lafarge utilized soils from another property in Newton Township for most of the capping. The soils ranged from quality clay to unacceptable silt. As the clay depleted, soils previously determined to be sub-marginal apparently became acceptable. If sub-marginal soils were used for the capping, the protective qualities of the cap would be further compromised. QA/QC sampling of the soil cap is needed to verify actual conditions.

A plastic cap would solve these problems but considering Lafarge’s long track record of recalcitrance and non-compliance, it won’t be coming anytime soon.

Markus Aurelius

citizensagainstlordstownlandfill.org

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.