Carbon neutrality targets stimulate the application of vacuum glass

MORN GLASS

The Net Zero Emission Tracking Table of Energy & Climate Intelligence Unit counts the progress of each country. As of now, 85% of the world total population has set a net zero emission plan.

In order to achieve the set carbon neutrality goal, it is necessary to save energy, especially building energy consumption.

Building energy consumption accounts for more than 1/3 of the total global energy consumption, more than 40% in developed countries, and more than 20% in China. Among them, air conditioners account 2/3 of building energy consumers. Therefore, adopting new energy efficient doors and windows and glass is important measure to achieve the carbon neutrality goal.

Compared with the traditional insulating glass, the new revolutionary vacuum glass has become a new type of energy-saving glass preferred by architects and homeowners.

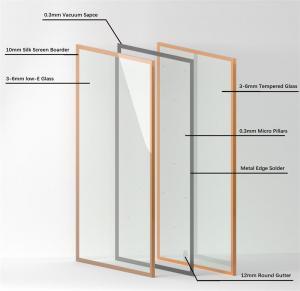

Different from traditional insulating glass, there is a vacuum space of 0.15-0.3mm in the middle of vacuum glass, which not only greatly reduces the total thickness of the glass, saves the load of door and window frame, and prolongs the lifetime.

More importantly, the vacuum layer eliminates the medium of air convection and conduction of solar energy through the air, and the advanced low-E film can reflect up to 85% of the solar radiation heat, making the insulation performance of vacuum glass only 1/4 of that of insulating glass ,which helps saving up to 75% air-conditioning energy.

Since vacuum glass was invented in 1993, there have been many vacuum glass manufacturers in the world, such as AGC-Fineo, Guardian-Spacia, Landvac, whose products are used in small-scale freezers and the renovation of historic buildings.

benefiting from the world construction market and strong demand, more and more companies are working hard to develop new technologies to apply vacuum glass in doors, windows, and curtain walls.

“Limited by the size, strength and limited production capacity of vacuum glass, although vacuum glass has been developed for 28 years, it is still not widely used on building curtain walls.” -Said by Mr. Han Xiaoqing, General Manager of MORN BM.

As new player,Morn just developed stable tempered vacuum glass.Compared with other vacuum glass products, Morn's vacuum glass products can expand the application of vacuum glass benefit from stable quality, better appearance, better price, and higher output.

The glass can be replaced directly without replacing the door and window system, and it can be applied to new high-rise buildings on a large scale. The size, self-explosion rate, and mechanical properties can meet the new high requirements.

Vacuum insulating glass was inspired by thermo flask ,and stimulated by the world growing carbon neutrality targets,in the next decades,vacuum insulating glass will become the trend and contribute to a low carbon world.

Xiao Qing Han

MORN BM

+86 177 0546 4660

info@vacuum-glass.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.