Countdown to K2019 - Ge-Shen Exhibits LSR Demo Tool at K 2019

The Malaysia-based System Integrator and Solution Provider presents its new LSR demo tool at K 2019.

Ge-Shen Corporation Berhad (KLSE:GESHEN)

KUALA LUMPUR, MALAYSIA, October 16, 2019 /EINPresswire.com/ -- Right in time for K 2019 (Dusseldorf, Germany, 16th - 23rd October 2019), the world’s leading trade fair for the plastic and rubber industry to open its doors, Ge-Shen has successfully finished the challenging task of manufacturing a LSR demo tool, of which they will exhibit the product at their booth in Hall 8b / H70. Design and manufacture of this LSR product from scratch has proven an excellent opportunity for the highly skilled and committed team of Ge-Shen to benefit from a steep learning curve in working with the material as well as getting hands-on experience, the result of which Ge-Shen is eager to share with their existing and future customers at the fair. As the saying goes: A fine part speaks more than a thousand words.LSR – the abbreviation standing for Liquid Silicone Rubber is indispensable in innovative manufacturing processes. Being a very versatile material it is ideal for making parts that suit themselves to a wide variety of applications in the medical, industrial or consumer industries. At the same time it is undoubtedly a challenging material to work with. This is exactly where Ge-Shen, with its long-standing manufacturing expertise, dedicated workforce and innovative drive comes into the equation. By not only understanding their customers’ needs and therefore providing the fitting solution for their demand, but by taking all this a step further to gain a deep understanding of the material is key to the holistic approach Ge-Shen though which strives to fulfill and exceed customers’ needs. Thanks to Ge-Shen’s extensive and excellent network of key material suppliers with vast knowledge and expertise in LSR processing, customer solutions can be developed and manufactured in a unique way – the Ge-Shen way.

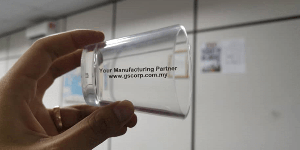

The result of this will be showcased at K 2019. To see is to believe, so Ge-Shen decided to produce one of the most universal forms, a form which clearly demonstrates its manufacturing capabilities, a form which customers will be happy to use and which will convince them during each and every use of the form of the quality of Ge-Shen’s LSR moulding – a DRINKING GLASS. This will be given to visitors to the booth as a sample.

This form, manufactured by utilising their CAE flow simulation software Moldex3D to simulate the processing and hence eliminate any manufacturability issues right before the actual manufacturing process helps to nip any further costs which might arise after production right in the bud and thus keep costs under control and project times short.

The availability of Ge-Shen’s in-house tool team with the ability to support any repairs, modifications or last-minute changes to tools should they arise also forms an integral part of Ge-Shen’s quality and guarantees the smooth running of any customer project.

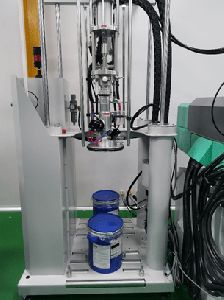

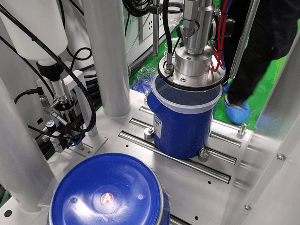

Manufacturing of parts with LSR is a challenging process as basically typical processing parameters must be reversed. As LSR cures in heat, it must be kept cool right through the machine and has to be heated up in the mould. LSR consists of the “A” part and the “B” part. With Ge-Shen’s 2KM dosing unit each pail is loaded on their respective sides and careful setting of the machine ensures that they are mixed in an exact 1:1 ratio. Whilst the material is being loaded, the tools are set up and the heaters and thermocouples are connected to Ge-Shen’s Arburg 520 A injection moulding machine. In the next step the production parameters are to be defined.

Though not exactly rocket science, this process demands vast technological expertise, a dedicated team and a deep understanding of customer needs – all that is in a nutshell exactly what Ge-Shen offers its customers.

Be it Plastic or Liquid Silicon Rubber components, metal fabrication and stamping, Coating and Surface Finishing or the complete assembly of your products - let Ge-Shen Group be YOUR Solution Provider and manufacturing partner. 100%, 360 degrees, 24/7 – trusted, certified, innovative, committed.

Visit us at K 2019 in Hall 8b / H70 (booth name of subsidiary POLYPLAS SDN. BHD

Louis Lau

Ge-Shen Corporation Berhad

+60 3-2785 0975

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.