AI Brings Predictability to Complex Food Product Development

A new review shows how AI helps food companies predict formulation, processing, and sensory outcomes.

Most food R&D still relies on experience-based formulation, pilot trials, and sensory testing. These approaches work well for incremental improvement, but they become inefficient as ingredient systems grow more complex and development timelines shorten. In many cases, formulation and quality decisions are made reactively, after problems appear, rather than predictively.

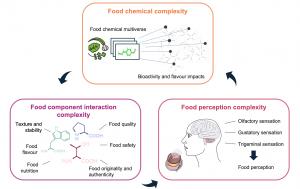

A recent open-access review published in npj Science of Food argues that artificial intelligence (AI), particularly machine learning, can help address this challenge. Authored by researchers from the National University of Singapore and Shanghai Institute of Technology, the review proposes a three-layer view of food complexity—molecular composition, food component interactions, and human perception—as a practical way to organize data and guide decision-making in food R&D.

From molecular data to practical ingredient screening

At the molecular level, foods contain far more chemical diversity than R&D teams can manually interpret. Although analytical tools such as GC–MS and LC–MS are widely used in industry, the resulting datasets are often underexploited. Machine learning models can link molecular structure to functional or sensory properties, making it possible to screen and prioritize ingredients more efficiently.

In practice, this allows companies to narrow down candidate flavor compounds, bioactives, or processing-derived molecules earlier in development. Instead of testing every option experimentally, teams can focus resources on the most promising candidates.

Understanding ingredient interactions in real food systems

Many formulation challenges—such as flavor masking, off-notes, texture instability, or batch-to-batch variation—do not originate from single ingredients. They emerge from interactions among multiple components within real food matrices. These effects are often nonlinear and depend on formulation and processing conditions.

The review describes how AI models trained on instrumental data and sensor signals, including electronic noses and tongues, can learn these interaction patterns directly from data. When information from multiple analytical platforms is combined, models become better at anticipating how changes in formulation or processing will affect quality and sensory performance. This supports a more predictive approach to formulation, reducing reliance on repeated trial-and-error experiments.

Linking chemistry to perception

Consumer perception ultimately determines product success, yet sensory evaluation remains time-consuming and difficult to scale. The authors discuss early efforts to combine AI with neuroinformatics tools such as EEG and fNIRS to study how consumers respond to food at a physiological level.

Although these methods are still developing, they point to future possibilities for more objective sensory insights and better understanding of consumer variability, particularly in areas such as health-focused and sustainable products.

Making AI usable in industrial settings

A key message of the review is that no single data source is sufficient. Predictive models become useful only when molecular data, instrumental measurements, and sensory information are combined through data fusion. At the same time, industrial adoption requires models that are interpretable, robust across sites, and compatible with existing workflows.

“AI does not replace food scientists—it helps them work more effectively with complex data,” said Dr. Dachuan Zhang, corresponding author. “The goal is to turn experience into structured knowledge that can scale.”

Dr. Xingran Kou, co-corresponding author, added: “Moving from trial-and-error to predictive design is a major opportunity for the food industry. Once complexity becomes computable, development becomes faster and more reliable.”

The authors conclude that viewing food complexity through molecular, interaction, and perception layers provides a practical roadmap for integrating AI into food R&D and quality control, helping companies manage complexity rather than be constrained by it.

Publication details:

Ke, Q., Zhang, J., Huang, X., Kou, X., & Zhang, D. Machine learning unveils three layers of food complexity. npj Science of Food (2026).

https://doi.org/10.1038/s41538-026-00730-w (open-access)

Dachuan Zhang

FoodAI Research Group at NUS

dachuan.zhang@nus.edu.sg

Visit us on social media:

LinkedIn

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.