Collaboration at the Core: Tesla Mechanical Designs' Vendor Synergy Accelerates Product Development

The firm’s engineering-led approach integrates key manufacturing partners into the design phase, eliminating DFM errors & reducing time-to-market.

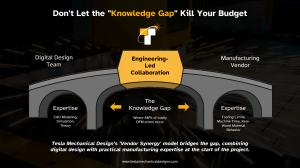

𝐌𝐚𝐧𝐮𝐟𝐚𝐜𝐭𝐮𝐫𝐢𝐧𝐠'𝐬 𝐌𝐨𝐬𝐭 𝐄𝐱𝐩𝐞𝐧𝐬𝐢𝐯𝐞 𝐏𝐫𝐨𝐛𝐥𝐞𝐦: 𝐓𝐡𝐞 '𝐊𝐧𝐨𝐰𝐥𝐞𝐝𝐠𝐞 𝐆𝐚𝐩'

In a traditional product development cycle, a design is completed in a silo, then "thrown over the wall" to a manufacturer for a quote. It is often only at this late stage that critical DFM (Design for Manufacturability) flaws are discovered—a specific blend radius is impossible to tool, a material is too brittle for the forming process, or a tolerance is unnecessarily tight, driving up cost. This discovery forces a costly and time-consuming redesign loop, which is the primary cause of budget overruns and project delays.

Tesla Mechanical Designs' entire workflow is engineered to prevent this exact scenario. The firm operates as a central "hub," leading a collaborative ecosystem of designers, clients, and manufacturing experts.

𝐓𝐡𝐞 𝐒𝐲𝐧𝐞𝐫𝐠𝐲 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧: 𝐂𝐨-𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐧𝐠 𝐭𝐡𝐞 𝐃𝐞𝐬𝐢𝐠𝐧

The company model is not just about managing suppliers; it's about integrating their expertise and leveraging it to drive innovation. This "vendor synergy" is a proactive process:

✔️ 𝐄𝐚𝐫𝐥𝐲-𝐒𝐭𝐚𝐠𝐞 𝐈𝐧𝐭𝐞𝐠𝐫𝐚𝐭𝐢𝐨𝐧: When engineers begin a complex Sheet Metal Design or a Custom Machine Design, they bring their vetted, specialized fabrication partner into the initial design reviews.

✔️ 𝐏𝐫𝐚𝐜𝐭𝐢𝐜𝐚𝐥 𝐄𝐱𝐩𝐞𝐫𝐭𝐢𝐬𝐞 𝐌𝐞𝐞𝐭𝐬 𝐃𝐢𝐠𝐢𝐭𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧: The manufacturing expert provides immediate, hands-on feedback on real-world constraints: material behavior, tooling limitations, and assembly efficiencies.

✔️ 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠-𝐋𝐞𝐝 𝐑𝐞𝐟𝐢𝐧𝐞𝐦𝐞𝐧𝐭: The engineers—the "core" of the collaboration—then translate this practical feedback into the digital model. They refine the CAD 3D Modeling, adjust Mechanical Component Design, and update Mechanical Drawings, ensuring the final design is not just theoretically sound but also optimized for the most efficient production path.

𝐇𝐨𝐰 𝐒𝐲𝐧𝐞𝐫𝐠𝐲 𝐃𝐞𝐥𝐢𝐯𝐞𝐫𝐬 𝐓𝐚𝐧𝐠𝐢𝐛𝐥𝐞 𝐂𝐥𝐢𝐞𝐧𝐭 𝐕𝐚𝐥𝐮𝐞

This collaborative, "co-innovation" model creates a more robust and efficient Product Development cycle, delivering clear, tangible benefits:

👉🏻 𝐄𝐥𝐢𝐦𝐢𝐧𝐚𝐭𝐞𝐬 𝐂𝐨𝐬𝐭𝐥𝐲 𝐃𝐅𝐌 𝐄𝐫𝐫𝐨𝐫𝐬: By fusing digital design with physical manufacturing knowledge from day one, this model identifies and solves over 90% of DFM and tooling conflicts before the prototyping phase.

👉🏻 𝐒𝐥𝐚𝐬𝐡𝐞𝐬 𝐓𝐢𝐦𝐞-𝐭𝐨-𝐌𝐚𝐫𝐤𝐞𝐭: The "redesign loop" is completely eliminated. This allows for a more accurate, predictable, and accelerated project timeline, supporting TMD's proactive, "day-in-advance" workflow.

👉🏻 𝐋𝐨𝐰𝐞𝐫𝐬 𝐓𝐨𝐭𝐚𝐥 𝐂𝐨𝐬𝐭 𝐨𝐟 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧: Products are designed from the start to be as cost-effective to manufacture as possible. This process identifies opportunities for material savings, simplified assembly, and faster machine times, directly lowering the client's total cost of ownership.

👉🏻 𝐀 𝐁𝐞𝐭𝐭𝐞𝐫, 𝐌𝐨𝐫𝐞 𝐑𝐨𝐛𝐮𝐬𝐭 𝐏𝐫𝐨𝐝𝐮𝐜𝐭: This synergy results in a superior product. The final design is an optimized blend of cutting-edge digital simulation (like Advanced FEA Services) and practical, time-tested manufacturing reality.

By acting as the expert integrator, Tesla Mechanical Designs ensures its clients receive a product that is not only innovative but also flawlessly engineered for rapid, cost-effective, and high-quality production.

𝐀𝐛𝐨𝐮𝐭 𝐓𝐞𝐬𝐥𝐚 𝐌𝐞𝐜𝐡𝐚𝐧𝐢𝐜𝐚𝐥 𝐃𝐞𝐬𝐢𝐠𝐧𝐬

Tesla Mechanical Designs is a premier engineering solutions firm that operates as a central hub for product innovation. The firm is built on a "synergy" model that integrates its core engineering team with a curated network of elite manufacturing partners. The firm’s mission is to lead a collaborative ecosystem that fuses digital design with practical fabrication expertise, eliminating the traditional conflicts that delay projects. By co-innovating with clients and partners, Tesla Mechanical Designs delivers products that are designed right, the first time.

Divya Dave

Tesla Mechanical Designs

+1 214-699-6163

email us here

Visit us on social media:

LinkedIn

Bluesky

Instagram

Facebook

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.