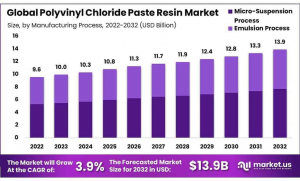

Polyvinyl Chloride Paste Resin Market to Reach $13,960.4 Million by 2032, Growing at 3.9% CAGR from 2023

Polyvinyl Chloride Paste Resin Market was valued at USD 9,598.7 Million and is expected to reach USD 13,960.4 Million in 2032 a CAGR of 3.9%.

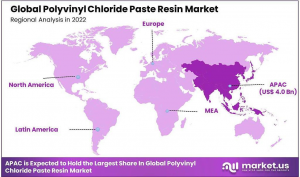

The Global Polyvinyl Chloride (PVC) Paste Resin Market was valued at USD 9,598.7 million in 2022 and is anticipated to reach USD 13,960.4 million by 2032, reflecting a steady CAGR of 3.9% from 2023 to 2032. PVC paste resin, provided as a white powder, is utilized extensively in numerous industries for the production of items such as plastic tiles, gloves, and artificial leather due to its durability, chemical resistance, and affordability. The construction sector significantly drives its demand, leveraging the resin's lightweight and cost-effective nature for uses like window frames and plumbing systems. However, fluctuating raw material costs and regulatory restrictions on phthalates, commonly used as plasticizers, pose challenges. The Asia-Pacific region, particularly China and Japan, leads market dominance, driven by extensive manufacturing capabilities and high demand in various applications like automotive interiors and construction.

👉 Request a free sample PDF report for valuable insights: https://market.us/report/polyvinyl-chloride-paste-resin-market/request-sample/

Experts Review:

Government incentives promoting infrastructure development and technological innovations in manufacturing processes are key driving forces for market growth. Investment opportunities are attractive due to the resin's expansive applications, though risks include volatile raw material prices and strict environmental regulations. Consumer awareness around sustainability is influencing market trends, pushing companies to adopt bio-based and recycled materials. Technologically, advancements are fostering better production efficiencies and expanded uses of PVC paste resin. The regulatory environment demands compliance with safety and environmental standards, challenging businesses to innovate in sustainable practices and products. Such dynamics create a complex landscape of growth potential and operational hurdles.

Report Segmentation:

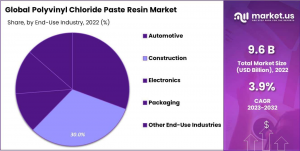

The PVC paste resin market is segmented by manufacturing process, grade, and end-use industry. The manufacturing processes include the micro-suspension and emulsion methods, with the former preferred for its effective processing characteristics. Grade-wise, high K-value grade dominates due to its superior mechanical and chemical resistance properties, beneficial in rigid pipe and structural applications. End-use industries range from automotive to packaging, with construction leading due to its significant reliance on PVC products for renovation and modernization projects. Segmentation allows a targeted analysis of market opportunities and offers insights into specific consumer demands and technological advancements relevant to each category. These segments highlight diverse application scenarios and market dynamics, catering to varied business strategies and investment objectives.

Key Market Segments

Based on the Manufacturing Process

• Micro-Suspension Process

• Emulsion Process

Based on Grade

• High K-Value Grade

• Mid K-Value Grade

• Low K-Value Grade

• Vinyl Acetate Copolymer Grade

• Blend Resin Grade

Based on End-Use Industry

• Automotive

• Construction

• Electronics

• Packaging

• Other End-Use Industries

👉 Buy Now to access the full report: https://market.us/purchase-report/?report_id=105652

Drivers, Restraints, Challenges, and Opportunities:

The market is driven by rising demands in construction and infrastructure modernization, supported by government investments and the preference for lightweight materials. Restraints are primarily due to fluctuating raw material costs and stringent regulations regarding phthalate use. Challenges include the need for technological innovations to ensure compliance and enhance product applications sustainably. However, opportunities abound in the retrofitting and renovation sectors, where PVC paste resin's versatility proves advantageous. Additionally, technological advancements present new possibilities for market players to develop innovative solutions and tap into emerging applications, sustaining industry growth amid evolving regulatory and consumer landscapes.

Key Player Analysis:

Key players shaping the market include industry giants like INEOS Group Limited, LG Chem, and Westlake Corporation. These companies leverage strategic product launches and partnerships to enhance market presence and drive competitive advantage. For instance, Westlake’s introduction of GreenVin® bio-attributed PVC signifies a commitment to sustainability and innovation. Acquisitions and mergers play pivotal roles in market expansion, enabling companies to enter new territories and mitigate competition impacts. Continuous research and development underscore these firms’ strategies, focusing on optimizing production processes and diversifying product offerings to meet evolving market demands and regulatory requirements.

Market Key Players

• INEOS Group Limited

• LG Chem

• Westlake Corporation

• Hanwha Solutions Corporation

• Orbia

• Tosoh Corporation

• Formosa Plastics Corporation

• SCG Chemicals Public Company Limited

• KANEKA CORPORATION

• Chemplast Sanmar

• Other Key Players

Recent Developments:

Recent trends emphasize sustainability and digital integration, with manufacturers increasingly incorporating recycled and bio-based materials in production. Westlake’s introduction of GreenVin® bio-attributed PVC exemplifies this move towards environmentally conscious products. Additionally, technological integration, such as using IoT and smart sensors, is gaining traction, aiming to enhance infrastructure management and product lifecycle efficiency. These advancements reflect an industry pivot towards more sustainable and intelligent manufacturing processes, aligning with global efforts to reduce carbon footprints and adapt to digital transformations, ultimately fostering industry resilience in response to environmental imperatives.

Conclusion:

The PVC paste resin market is poised for steady growth, driven by construction sector demands and technological innovations. While challenges like regulatory pressures and material price volatility persist, opportunities in sustainable practices and technological advancements present pathways for expansion. Key market players continue to adapt strategically, promoting development through sustainable, innovative product solutions. The focus on modernizing infrastructure and embracing environmentally friendly manufacturing practices will be crucial in navigating future market shifts, ensuring adaptability and competitiveness in this evolving industrial landscape.

Lawrence John

Prudour

+91 91308 55334

Lawrence@prudour.com

Visit us on social media:

Facebook

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.