PureForge Brake technology treatment eliminates rotor dust particulate emissions

Atomic-Forging™ WORKS!

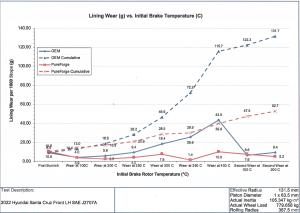

PONTIAC, MI, UNITED STATES, September 10, 2024 /EINPresswire.com/ -- “We can PROVE it” says Dave Sherman, PureForge Director of Testing and Customer Interface. Link Engineering third party independent testing has proven that PureForge rotors do not wear, thus eliminating particulate emissions that come from rotor wear. “In fact, SAE J2707 test data shows that the rotor actually gained thickness and mass”, Sherman added.Results of SAE J2707 Rotor Wear vs Temperature.

Test Vehicle: Small Crossover SUV, Gross Vehicle Weight = 2600 Kg

Specifications: Rotor Diameter = 325 MM

(Testing conducted by Link Engineering, Dearborn Michigan)

Test Observations:

OEM Rotor Cumulative Wear Results (Loss of 29.10 grams).

PureForge Treated Rotor Cumulative Wear Results (Gain of 13.20 grams).

Conclusion:

The PureForge rotor gained mass versus the OEM rotor losing mass (net difference OEM loss to PureForge gain is 42.30 grams).

Results of SAE J2707 Pad Wear vs Temperature.

Test Vehicle: Small Crossover SUV, Gross Vehicle Weight = 2600 Kg

Specifications: Rotor Diameter = 325 MM

(Testing conducted by Link Engineering, Dearborn Michigan)

Test Observations:

OEM Pad Cumulative Wear Results (Loss of 131.7 grams).

PureForge Formulation Pad Cumulative Wear Results (Loss of 52.7 grams).

Conclusion:

The PureForge Formulation Pad had a 60% improvement in mass loss versus the OEM Pad.

Overall Conclusion:

PureForge Treated Rotors do not wear, they gain mass and thickness.

PureForge Formulation Pads, when used with Atomic-Forged treated rotors, wear at a significantly lower rate.

PureForge Technology clearly provides an environmental advantage through reducing vehicle emissions over the life of the vehicle due to our increased longevity.

“The PureForge state-of-the-art Atomic-Forging process applied to a cast iron rotor, coupled with a pad formulation designed to take advantage of the Atomic-Forged rotor, provides the benefits of reduced brake dust and longer overall brake life resulting in greatly reduced brake service intervals”, said Paul Stoloff, PureForge VP OEM Production Engineering.

For more information or to order products, go to our website www.pureforge.com or please contact:

Dave Sherman

PureForge Inc.

40 W Pike St, Pontiac, MI 48342

248-481-7096

dsherman@pureforge.com

Dave Sherman

PureForge

+1 248-481-7096

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.