Blue Ink Tech provides gross and axle weights with bluetooth truck scales

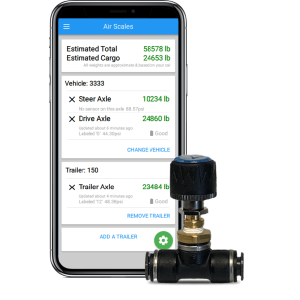

Carriers and drivers can now get their steer, drive, trailer, gross and cargo weights of their trucks and trailers on their phone with the Blue Ink Tech app

HUNTINGTON, WV, US, November 8, 2022 /EINPresswire.com/ -- Blue Ink Tech, maker of the BIT ELD, has released the most recent addition to its BIT Full Service Platform.BIT Air Scale gives drivers access to real-time weight information on their phone or tablet using the BIT app. Utilizing two small, wireless sensors, BIT Air Scale self-installs in less than 15 minutes. “With time tighter than ever, BIT Air Scale frees drivers from the necessity of visiting an off-site scale to find out their weight,” said Mike Riegel, head of product development. “Anyone who hauls bulk, is paid by weight, or loads in locations without easy access to scales should be paying attention to this system.”

The system integrates into Blue Ink Tech’s web portal allowing carriers to see how much weight each of their trucks is carrying at any given moment. Riegel said Blue Ink Tech had moved to solve one of the biggest friction points in trucking. “If a driver gets overloaded and doesn’t find out until they hit a scale 30 or 40 miles away, it really puts them in a tight spot,” Mike Riegel of Blue Ink Tech said. “They can either drive back to the shipper and correct the load, which could waste a whole day, or they can drive illegally. Either option ends up with the driver bearing the brunt of the problem, and the carrier potentially losing money.”

Blue Ink Tech aimed to solve this problem by allowing drivers to get accurate, real-time, weight at the point of loading, he said. “We wanted to make something as simple as possible on the customer’s side. All the complexity, all the math, happens in the app. For the customer, it’s as simple as install sensors, calibrate, done.”

Because the app delivers real-time updates on weight, a driver can monitor weight as the truck is being loaded.

For anyone hauling irregular loads that need to be tied down before the truck moves, this can be a huge time-saver. Ensuring

the load is in the right place and within legal limits, before you tie down can save hours, Riegel said.

Blue Ink Tech has managed to make the process of installation and calibration easy. Sensors come mounted on DOT approved Tee-fittings. They install directly into the suspension airline, with no need for additional wiring. Once the sensors are in place, a driver weighs their truck twice, once empty and once full, and enters the weights into the app. After that, the system handles the rest.

“With Blue Ink Tech’s app doing the heavy lifting, the system even calculates your steer axle,” Riegel said. “Air Scale provides a 99 percent accurate axle weight and gross combined weight.

The system integrates into Blue Ink Tech’s web portal allowing carriers to see how much weight each of their trucks is carrying at any given moment. Those using Blue Ink Tech’s other systems, will see weight, location, tire pressure, and the driver’s available hours of service, all in one place.”

You can learn more about the BIT Air Scales at blueinktech.com/air_scale.php

Mike Riegel

Blue Ink Technology

+1 304-381-1512

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Blue Ink Tech Air Scale Installation Guide

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.