DOE Awards Ampcera and LLNL $1.5M to Use 3D Printing for Faster Charging and Higher Energy Density Lithium Batteries

A national lab and industry partnership to innovative manufacturing processes for lithium-ion batteries and reduce time-to-market.

The joint project between LLNL and Ampcera is one of six Energy Systems projects selected for an award from DOE’s Advanced Manufacturing Office to reduce industrial emissions and manufacture clean energy technologies.

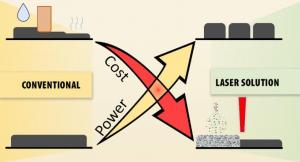

The proposed dry additive manufacturing technology is highly energy-efficient with >10 times the throughput of conventional slurry-based processing, reducing lithium battery manufacturing costs by 50% or more.

“The environmentally benign process allows for thick high-capacity 3D cathode structures to be processed, enabling lithium-ion batteries to reach the fast-charging goal of 80% charge in 15 minutes or less,” said staff scientist and principal investigator Jianchao Ye of LLNL.

As an innovator in developing and manufacturing advanced materials for solid-state batteries, Ampcera has a vested interest in this project. In addition to developing structured cathodes for lithium-ion batteries, Ampcera also plans to further develop this technology for manufacturing solid-state batteries.

“The partnership between LLNL and Ampcera will accelerate the development and commercialization of the ultra-fast and low-cost additive manufacturing technology for high-performance lithium battery manufacturing. After developing 3D-structured cathodes, we expect to expand the technology to anode design and also further explore its application in all-solid-state Li metal batteries with even higher energy and power densities,” said co-investigator Hui Du, Chief Technology Officer and Co-Founder of Ampcera.

“Ampcera is supporting this project as we believe it has the potential to revolutionize the scaled manufacturing of solid-state batteries with intrinsic safety, high energy density >450 Wh/kg, and a low cost of <$75 per kWh,” said Sumin Zhu, Chief Executive Officer and Co-Founder of Ampcera.

To learn more about Ampcera and opportunities for partnership, please visit Ampcera.com.

About Ampcera Inc.

Ampcera is a U.S.-based innovator in the development and commercialization of high-performance solid-state electrolyte materials and scalable manufacturing processes for next-generation lithium batteries. Ampcera is headquartered in the Silicon Valley in California with R&D and production facilities in Tucson, Arizona.

Sumin Zhu

Ampcera Inc.

info@ampcera.com

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.