Ekosolve Direct lithium Extraction Achieves more than 90% Recovery from SPEY Incahuasi Salar lithium brines

Ekosolve Direct Lithium Extraction solvent-exchange system (www.ekosolve.com.au) has recovered more than 90% of the available lithium for SPEY Resources.

ACHIEVES GREATER THAN 90% RECOVERY

Ekosolve Lithium Limited (www.ekosolve.com.au) announces that its Direct Lithium Extraction Technology pilot plant work completed for its newest client, Spey Resources Corporation (CSE:SPEY), has processed lithium brines from the Incahuasi Salar and achieved a remarkable recovery of greater than 90%. 200L of brine was processed, and high-grade lithium chloride was produced. The lithium chloride can be converted to battery-grade lithium carbonate or used as feeder stock for other lithium compounds.

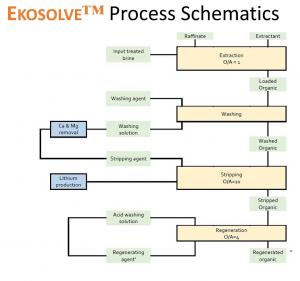

Solvent Exchange technology has been tried and tested since 1959 in the minerals industry, and the Ekosolve system has developed the technology to a new level of sophistication, targeting the direct extraction of lithium. Lithium producers from brines now have immediate access to a construction-ready, tailored system to produce lithium carbonate.

Ekosolve™ technology cuts capital and operating costs and accelerates project start-up with:

• Substantial reduction in CAPEX compared to other systems

• Low OPEX, very competitive with other processes

• No need for evaporation ponds or front-end scrubbing processes

• Increases total lithium recovery to more than 90%.

• Provides production flexibility being capable of modular units in multiples of 5000 tonne plants (10,000, 15,000 or 20,000+ tonne plants).

• Handles very high magnesium levels efficiently (Key innovation)

• Green energy footprint with solar and batteries to drive electrical motors

• Operates efficiently at high altitude

The Ekosolve™ system can be expanded in modules and be ramped up quickly through pilot or mini plants and then a commercial project, with no limit on size.

For further Information contact:

Phil Thomas admin @ ekosolve.com.au

+13235155164 or +61433747380 Whats App

Dr Carlos Sorentino cmrs26 @ gmail.com

www.ekosolve.com.au

Phillip Thomas

Ekosolve Limited

+61 433 747 380

philthomas@panopus.net

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.