Dos and Don’ts of Assembling Threaded Plastic Fittings

Dos and Don’ts of Assembling Threaded Plastic Fittings to Prevent Leaks

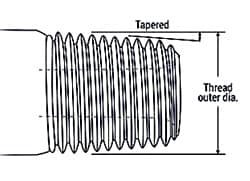

Tapered Thread

Don’t over-tighten joints.

On threaded male plastic fittings, each successive thread is slightly larger in diameter than the one before it. Female threads get successively smaller. This is called “taper” and the amount of taper is specified in the American National Standard B2.1. All pipe manufacturers voluntarily follow these standards to assure their customers they are receiving quality materials.

Because the threads are tapered, too many turns cause the female part to stretch or undergo “Strain.” This will split the female fitting just as a wedge, driven by a sledgehammer, will split a tree stump.

The amount of Strain increases as the size of the pipe decreases. Therefore, it is easier to split smaller diameter threaded joints than larger ones. It is also easier to over-torque smaller diameter fittings because their resistance to torque is less.

The right way to assemble a threaded plastic joint is to finger tighten, and then add no more than ½ to ¾ turn.

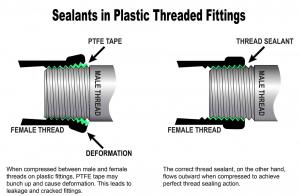

Don’t wrap PTFE tape on plastic fittings.

PTFE tape is intended for metal pipe and fittings. Metal-to-metal fitting joints are more difficult to tighten than plastic; the surfaces tend to gall without the aid of such lubricants as PTFE or pipe dope.

When PTFE tape is wrapped around plastic male threads, it packs the threads, increases the pipe diameter, prevents the pipe threads from meshing properly, and adds strain and tensile stress.

Use a sealant for threaded joints.

When working with threaded plastic fittings, select the correct sealant for the pipe and material. The right sealant for threaded joints is compatible with plastic and adds a little slipperiness.

Many brands of pipe sealant contain solvents or carriers that damage the plastic. A proper sealant must be certified by the manufacturer to be harmless to the fitting material, and to not contaminate the material in the pipe. "Fluoramics Formula-8 and Lox-8 Paste are safe to use with plastic pipes and fittings, including nylon. Be sure to properly apply thread sealants.” said Gregg Reick, President and Chief Engineer of Fluoramics.

Finally, a sealing compound must lubricate the joint enough to allow for a smooth tightening of the assembly and the uniform meshing of the mating pipe threads. Several sealants on the market meet all these requirements.

Schedule 80 threaded fittings will not solve the problem of splitting caused by over-tightening.

Many plastic piping system installers who encounter problems with splitting assume Schedule 40 fittings are weak. They conclude that the problem can be solved by switching to “stronger” Schedule 80 fittings. There are several errors in this reasoning.

First, all the problems inherent in over-tightening apply as much to Schedule 80 systems as they do Schedule 40. While the walls of female Schedule 80 threaded fittings are thicker, wall thickness does not change stress and strain levels.

Second, installers believe Schedule 80 systems are stronger because they have higher pressure ratings than Schedule 40 systems. This is true only when comparing systems with components that have been joined together with a solvent cement. This decrease in rating is due to a reduction of the fitting’s wall thickness caused by threads. In addition, most plastics are “notch sensitive.” When the smooth wall of a plastic part is notched, the part loses a significant portion of its original strength, just as a thick sheet of glass will break along a scribed line on its surface.

Don’t mix Schedule 40 threaded fittings with Schedule 80 pipe and fittings.

Since the outer diameter of schedule 40 is the same as schedule 80, it’s tempting to mix up the two types. However, it’s imperative to understand that the entire pipeline system is only as strong as the weakest part. This means using just one Schedule 40 PVC fitting lowers the entire PSI of the pipeline and going above that PSI can lead to a failure in the pipeline.

Fluoramics, Inc. is a solutions provider manufacturing engineered sealants, greases, lubricants, and rust inhibitors. Founded in 1967, the company is based in Winona, Minnesota, and proudly manufactures its products in the United States. To learn more about Fluoramics’ products, please visit the company's website at http://www.fluoramics.com.

Article adapted in part from The Do’s and Don’ts of Assembling Threaded PVC Fittings by Larry Workman, PVC Forensics, Consultant, Trainer at Expert4PVC Consulting. Published Jul 30, 2018

Patti Reick

Fluoramics, Inc.

+1 507-205-9216

email us here

Applying Thread Sealant on Plastic Fittings to Stop Leaks without Over-Torquing and Cracking

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.