Start Prototyping Has Started Manufacturing CNG Machining Services in China

START PROTOTYPING has achieved a milestone by inaugurating their CNG machining services which definitely will boost their business turnover in upcoming years.

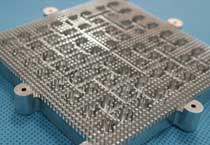

HUIZHOU, GUANGDONG, CHINA, April 24, 2020 /EINPresswire.com/ -- One of the significant Rapid prototyping service company START PROTOTYPING recently has embarked on a new journey by introducing the most most-awaited CNG machining services in China. They are currently offering considerable variations in this category like surface grinding, turning, milling, EDM wire, EDM and many more.This company is a one-stop solution for communications electronics, home appliances, medical, automotive and other several industries which require metal and plastic prototypes. But now along with that they are enabling their customers to choose from a broad range of services like CNG machining, CNG milling, CNG precision parts both in metals and plastic, CNG bending are a few to name. They assure guarantee on each of their product and similarly, for this particular category also they use imported best-quality 3, 4 and 5-axis CNG machining centres. These specifications not only ensure the top- quality product but also perfectly complement their 3D metal printing services.

The high-speed and high-accuracy of the products of this range proposes the best designing. This CNG prototyping services can be a great deal for designers and engineers who are working in the R&D department. Along with the service, they have also employed some highly professional mechanists who deliver the products on time and accurately. The automatic cutting tools can efficiently scrapes away substance from a specific portion from the pre-existing component according to customer’s designing needs. To make the whole process hassle-free and precise, they use advanced software to operate several gears in accord with those directives of their customer’s CAD files.

The spokesperson of the company said, “Our CNG machining services proposes plenty of advantages and benefits that are worth for money. Our pivotal goal is to satiate the needs of our customers by extending phenomenal services. We never ask our clients to pay extra for preparation expense moreover we assure highly accurate services.” The CNG machining contains an array of advantages which plays a significant role to cater to the customers’ product development needs as they are suitable for different kinds of substrates.

Just like their rapid prototyping service, the success of this new segment is just a matter of time. CNG machining makes possible low investment in tooling and preparation costs. Since it is highly accurate and repeatable, instant removal of a large amount of metal material has become easier. Also, the scalable volume ranges from one to as high as 100,000. The other merits of this service include factors like it is economical, fast turnaround and several others.

Their qualified team of machinists programs the tools in such a way so that they can optimise cutting time, final tolerance and surface finish for an accurate designing specification. They not only use prototyping machines to produce finished products but also craft mold equipment which could be utilised later for pressure die casting of plastic injection molding. The reputation of this company largely depends on the fact that they concentrate on every detail and top-notch quality of every product. Their quality control team has experience in this field for years now, and they make sure every part of the product is thoroughly checked before shipment.

This company has come a long way and yet to reach many benchmarks through their quality and wide range of products.

About the company:

With glorious ten years of experience, START PROTOTYPING is a prestigious rapid-prototyping, tooling and specialised low-volume device manufacturing company in China. They have started their journey since 2010 and holds AFAQ ISO/TS 16949, UL and ISO certifications. With the strength of 250 professionals, they operate a 20,000 square meters of factory building where they design and manufacture rapid prototype machining. With their comprehensive machining capacity and strict quality analysis and inspection of all products, they supply to several renowned 3D print companies around the world. Currently, they are equipped with 55 machines for robotics and automatic plastic injection manufacturing. This company is capable of maintaining high-efficiency, high-quality, short delivery and low-cost project operation for all of their production.

James Yuan

China Prototyping Expert

+86 752-6682869

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.