Hybrid Non-Isocyanate Polyurethanes (HNIPU) Market to Reach 10.1 Million USD by 2027

HNIPU, also called "Green Polyurethane" have found to have high-performance characteristics in them without causing the health and safety issues

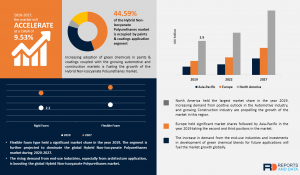

NEW YORK CITY, NEW YORK, UNITED STATES, March 11, 2020 /EINPresswire.com/ -- Market SummaryThe Hybrid Non-Isocyanate Polyurethanes (HNIPU) market is valued at 4.9 Million USD in 2019 and is supposed to reach 10.1 Million USD by the end of 2027, growing at a CAGR of 9.5% during 2019-2027. In this study, the year 2018 has been considered as the base year and the period from 2019 to 2027 for the forecast period to evaluate the market size for Hybrid Non-Isocyanate Polyurethanes (HNIPU).

Hybrid Non-Isocyanate Polyurethanes have elements and characteristics such as high hydrolytic stability, superior chemical resistance, adhesiveness, and reduced permeability as opposed to traditional polyurethanes in the market. HNIPUs also find applications in chemical resistant coatings, industrial flooring, sealants, and glues, among others.

These polyurethanes, also called "Green Polyurethane" have found to have high-performance characteristics in them without causing the health and safety issues associated with isocyanate and other materials. Hybrid Non-Isocyanate Polyurethanes is a material that is still under experimentation but has proved that its applications in the coatings, indoor and outdoor paints and floorings, and packaging in between the others. Hybrid Coating Technologies has been developing hybrid non-isocyanate polyurethane (HNIPU) through its patented technology, and this is the only formulation in the world in today's era.

Request free sample of this research report at: https://www.reportsanddata.com/sample-enquiry-form/2618

The synthesis of HNIPU is quite safe and flexible to use. Unlike any other conventional polyurethanes, Hybrid Non-Isocyanate Polyurethanes do not use isocyanate at any stage of production. Isocyanates are critical components used in the production of conventional polyurethane products such as coatings and foam. Exposure to these isocyanates is known to cause skin and respiratory problems and even death. Isocyanates are also toxic to the atmosphere and wildlife. When they are burned, they form toxic chemicals and corrosive fumes which includes nitrogen oxides and hydrogen cyanide like chemicals. Due to these hazards, isocyanates are being circulated by the EPA and other government bodies. HNIPU is processed from a reaction between the mixture of mono or polycyclic carbonate and epoxy oligomers and aliphatic/cycloaliphatic polyamines with primary amino groups. A cross-linked polymer is formed with β-hydroxy urethane groups of different structures and formations. The product's improved mechanical and chemical properties are finding its usage in the segment of paints, coatings, adhesives, sealants, flooring industries, etc. is cost-competitive compared to other conventional polyurethane and epoxy products.

Salient Trends of the Hybrid Non-Isocyanate Polyurethanes Market

• HNIPU is the modified polyurethane composition with lower permeability and properties, such as increased chemical resistance and material synthesis that does not use the toxic isocyanate.

• Polyurethanes contain amide as their repetitive unit, which is linked by a different hydroxy group. Polyurethane/epoxy hybrid materials from CO2-sourced monomer were prepared through an environmentally-friendly and non-toxic process, which avoids the use of toxic isocyanate.

• As per the recent scenario, more research needs to be conducted regarding the long-term effects of using Isocyanate products with Polyurethanes content. Due to the FDA\'s and European Commission the concerns about oral exposure, it is reasonable to be skeptical about its safety

• A series of non-isocyanate polyurethane (NIPU) and epoxy hybrid materials with different and controlled architectures in the industry, were synthesized from CO2, polypropylene glycol diglyceryl ether (PPGDGE), amines and diglyceryl ether of bisphenol-A (BADGE).

• The manufacturers are engaged in research & development and other activities and strategies such as mergers & acquisitions, contracts, collaboration, and new product launches, which are contributing to the industrial market and the pharmaceutical companies.

• In the application segment, the Industrial and paint/coating segment accounted for the largest market share in 2019. The rising demand from this sector is due to the environment-friendly use of the product.

• Around 12 wt. % CO2was incorporated into PPGDGE to form a five-membered cyclic carbonate (5CC-PPGDGE). The complete conversion and selectivity of PPGDGE were obtained.

• The Asia-Pacific region accounted for the leading share in terms of revenue generation, followed because of the growing disposable income and demand majorly from the regional architecture industry.

Order Your Copy Now (Customized report delivered as per your specific requirement) @ https://www.reportsanddata.com/checkout-form/2618

Market-O-Nomics

• As of 2019, Paints and Coatings are the leading type segment of the global HNIPU This segment is projected to register the fastest growth with the highest CAGR during the forecast period due to its outstanding low-temperature flexibility and flex fatigue coupled with good resistance to chemicals, weathering, wear and heat

• The Adhesive and Sealants segment has also shown the significant growth trend in 2019 and is expected to maintain the position during the forecast period

• The consumer goods application of the paints and coatings are accounted for the most significant market share in 2019. It is projected to maintain its lead with a significant CAGR during the forecast period

• The Rigid Foam (Paints) application segment is the fastest-growing segment, registering the highest CAGR followed by the medical segment which held the significant position in the hybrid non-isocyanate polyurethanes market

• The North America region accounted for the most significant market share of 59.3% in 2019. This region is proposed to remain the dominant regional segment with a significant CAGR during 2020-2027. The U.S. country is the fastest-growing economy, which is projected to drive the global hybrid non-isocyanate polyurethanes market.

• Both Europe and Middle Eastern regions are predicted to show a significant amount of growth over the coming years

To identify the key trends in the industry, click on the link below: https://www.reportsanddata.com/report-detail/hybrid-non-isocyanate-polyurethanes-hnipu-market

Segments Covered in the report

Type (Revenue, USD Million; Volume in Tons, 2017–2027)

• Rigid Foam

• Flexible Foam

Application (Revenue, USD Million; Volume in Tons, 2017–2027)

• Paints

• Coatings

• Adhesives

• Sealants

• Fiber-Reinforced Composites

• Others

End-Use (Revenue, USD Million; Volume in Tons, 2017–2027)

• Architectural

• Automotive Parts

• Medical

• Packaging

• Consumer goods

• Building and Construction

• Others

Regional Outlook (Revenue in USD Million; Volume in Tons, 2017–2027)

• North America

• Europe

• Asia Pacific

• Middle East & Africa

• Latin America

John Watson

Reports and Data

+1 212-710-1370

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.