CapTemp Smart Farming Solution for Poultry House Monitoring and Control Increases Stock Production by 20%

CapTemp developed a smart farming solution that monitors, controls & analyzes different assets of a poultry house for increased stock production.

POMPAL, PORTUGAL, PORTUGAL, January 21, 2019 /EINPresswire.com/ -- CapTemp developed a smart farming solution that monitors, controls and analyzes different assets of a poultry house for improved animal production. Previously, the poultry farmer did not have an automated monitoring system or data analytic tools to gain insights on livestock or farm equipment, resulting in stock production loss of 20%. To operate more profitably, the farmer needed to eliminate manual methods and implement an information technology tool that could connect, track, control and analyze different processes within the poultry house.Partnering with Equiporave Iberica, market leaders in pig and poultry equipment, CapTemp developed a sensor control system solution that collects and reports data on different parameters within the poultry house such as temperature, humidity and gases as well as machine energy consumption. Data logging and redundancy functions provide for a fail-safe solution with customized control features such as scheduled machine usage when energy is lower cost.

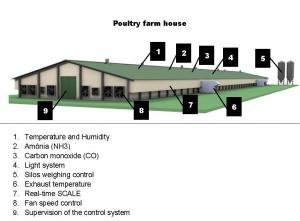

CapTemp implemented its Nidus-IT Monitoring and Control System that features temperature, humidity, CO2, CO, CH4, NH3 and H2S sensors installed on key equipment to monitor different operating conditions within the poultry house. CapTemp also installed Lda Feed-bin weight scales that allows famers and feed companies to assess feed levels in bins to improve feed distribution and logistics.

With the sensors networked to a central alarm system, operators are alerted of unusual conditions in real-time by Internet, e-mail, SMS or GSM. With information from the Nidus-IT Monitoring and Control System available over the Internet, operators can remotely monitor different parameters from a single location and make appropriate adjustments to environmental conditions.

Through the implementation of the CapTemp monitoring and control solution, the farmer:

• Reduced energy and feed costs due to better environmental conditions

• Improved daily weight gains for improved animal growth

• Reduced stock mortality rate to zero

• Reduced required medicines to improve health of stock

• Monitors and controls harmful gases (Nh3 and CO2) to maintain ideal environmental conditions to increase productivity index by 20 points.

Implementation of the CapTemp Nidus-IT monitoring and control system helped decrease mortality rates to zero while improving food transformation and stock mean weight while decreasing mean age. For nearly a decade, CapTemp and Equiporave Iberica collaborate on developing customized sensor control systems to help farmers operate smarter by staying connected with their different operations. For more information, please refer to the CapTemp website at https://captemp.com/solutions/agriculture&animal.php or contact Carlos Domingues at carlos@captemp.com.

About CapTemp

A Portuguese company, CapTemp develops monitoring, supervision and M2M remote control systems with IP sensors to ensure the safety of environmentally-sensitive environments as well as manage the consumption of resources such as water, gas and electricity. Pioneers of metrology software for monitoring temperatures, the company provides custom remote monitoring and management solutions to a diverse range of industries including healthcare, food & retail, transportation and logistics, agricultural and animal growth, data centers and business corporations. CapTemp USA based in New Hampshire serves as the US market. For more information, visit https://captemp.com/index.php.

Jean Carl

CapTemp

+1 610-565-9913

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.