New York City 3D Printing Company Offers Materials for Drones and Auto Parts

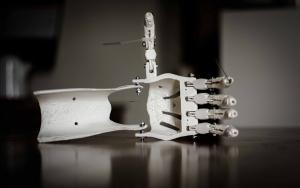

The rise of advanced materials for 3d printing to create auto and aerospace parts leads ThreeD Materials to offer a full suite of industrial strength filaments.

“When we started this company years ago, the primary emphasis was serving the needs of our customers in the educational sector. The goal was to ensure that teachers and students had the tools they needed to successfully leverage 3d printing for their learning needs. That still rings true today,” ThreeD Materials’ President Zachary Lichaa says, “however to meet the evolving needs of our customers, we have decided to offer a full stack of advanced 3d printing filaments and polymers for FFM/FDM technology. This includes nylons and advanced polymers for automotive, aerospace, health care and defense companies.

3D Printing Materials Now Available with ThreeD Materials

Nylon 230 - The First Nylon Filament to Print at 230C

Nylon 645 - possesses incredible strength, excellent elasticity and is lighter than ABS or PLA

Nylon 680 - FDA food and beverage complaint nylon filament

Alloy 910 - A single material that meets as many high performance 3d printing needs as possible, and a favorite of the drone community

Bridge Nylon - Combines the price of ABS and PLA filament with the durability of nylon

“Our customers are no longer just printing with basic plastics and following lesson plans. They are building spare parts for cars that the carmaker no longer makes, drones of all sizes, musical instruments and new piping for housing and office buildings” Lichaa said. “We are extremely excited that high performance materials for 3d printing can serve as a catalyst for the next generation of advanced manufacturing in America, and we plan to serve that customer base well.”

The advanced materials are now a compliment to an existing array of filaments, 3d printers, lesson plans, curriculums and customer support that ThreeD Materials has always offered.

“We believe 2017 is a year in which materials science and 3d printers are working together to change the design paradigm at Fortune 100 companies and inside the garages of engineers across the world,” Lichaa says. “That growing list of interested parties needs reliable expertise to go along with their acquisition of filaments for 3d printing, and ThreeD Materials is happy to serve them.”

Spencer Steele

ThreeD Materials

4019968868

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.