Kaijo Advances Ultrasonic Cleaning with Next-Generation Water Resonance System

Kaijo announces enhanced capabilities and expanded industry adoption of its Next-Generation Water Resonance System for Ultrasonic Cleaning

SANTA CLARA, CA, UNITED STATES, December 16, 2025 /EINPresswire.com/ -- Kaijo Corporation, a global leader among ultrasonic cleaner manufacturers, today announced enhanced capabilities and expanded industry adoption of its Next-Generation Water Resonance System (WRS)—the company’s proprietary advancement in ultrasonic cleaning designed to significantly improve cleaning performance, uniformity, and process efficiency across a wide range of manufacturing applications.

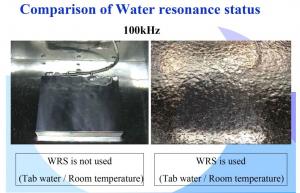

Kaijo’s Water Resonance System introduces a breakthrough in ultrasonic cleaning technology by propagating uniform, high-density ultrasonic waves throughout the entire cleaning bath. This resonance-driven distribution minimizes acoustic dead zones and dramatically increases cavitation energy, enabling deeper, more consistent cleaning of precision components. WRS integrates easily into Kaijo’s complete product line of industrial ultrasonic cleaners and can be used with any of Kaijo’s new and old systems, offering an efficient upgrade path without significant reinvestment.

Breakthrough in Cleaning Efficiency and Uniformity

The proprietary Water Resonance System enhances acoustic energy by generating higher bubble density with greater stability, strengthening cavitation, and improving particle removal. This results in:

• Superior cleaning uniformity across complex geometries, blind holes, micro-features, and internal cavities.

• Reduced cycle times, allowing manufacturers to boost throughput while maintaining or improving accuracy and consistency.

• Lower energy use, as optimized resonance enables stronger cleaning results at reduced power levels.

• Reduced chemical dependency, supporting lower hazardous waste output, less operator exposure, and improved environmental performance.

• Strengthened high-frequency cleaning, offering faster results at less aggressive frequencies for delicate parts.

• Increased acoustic energy for indirect cleaning applications, broadening the range of process capabilities.

These benefits directly support manufacturers’ goals of improving productivity, reducing operational costs, and achieving more reliable cleaning outcomes.

Proprietary Technology Engineered for Durability and Performance

Developed through decades of Kaijo engineering experience, WRS delivers performance levels not achievable with conventional ultrasonic systems. Testing shows that WRS may produce up to five times greater sound pressure than standard ultrasonic units, improving cleaning reach and accelerating the removal of fine contaminants.

Additionally, the system’s efficient energy-transfer design reduces mechanical strain on components, helping extend equipment lifespan by 3 to 10 times under appropriate operating conditions. The system’s longevity strengthens its value proposition for high-throughput and high-precision manufacturers.

“The Water Resonance System effectuates three-dimensional cleaning and maximizes cavitation energy for ultrasonic cleaners both new and old.” — Michael Danese, General Manager at Kaijo Shibuya America Inc.

Versatile Across Industries, Materials, and Cleaning Environments

WRS supports a wide range of industrial applications and materials, including:

• Metals, ceramics, glass, optics, PCBs, and semiconductor substrates

• Medical-device components and parts requiring sub-micron-level cleanliness

The system performs effectively in multiple environments—municipal water, deionized (DI) water, ionic water, or specialized chemistries—making it suitable for diverse production requirements. Its compatibility with both small precision tanks and large industrial cleaning systems enables broad deployment across R&D, batch production, and high-volume manufacturing settings.

Supports Safety, Compliance, and Sustainability Initiatives

As manufacturers prioritize safety and ESG commitments, WRS provides measurable value:

• Reduced chemical usage supports safer working conditions and lowers hazardous waste output.

• Lower power requirements help reduce energy consumption and operating costs.

• Uniform and repeatable cleaning results support compliance in sectors where consistency is critical, such as medical devices, aerospace, and semiconductor fabrication.

• Cleaner processes with less residue reduce the risk of product defects and improve downstream reliability.

Simple Integration and Scalable Adoption

Kaijo designed WRS for straightforward implementation. Facilities can retrofit the system onto many existing Kaijo ultrasonic installations, accelerating modernization efforts. WRS operates across a range of frequencies and power levels, making it easy for process engineers and facility managers to adopt without overhauling established workflows.

This scalable architecture supports applications in:

• High-throughput industrial cleaning

• Precision micro-cleaning environments

• Advanced manufacturing and assembly lines

• R&D and prototyping operations

Recognized Innovation Backed by Industry Leadership

Kaijo’s Water Resonance System has earned recognition from the Acoustical Society of Japan, receiving its Engineering & Development Award. This acknowledgment underscores the technical achievement behind WRS and Kaijo’s long-standing reputation as a global innovator in high-precision ultrasonic-cleaning solutions.

Meeting the Needs of Modern Manufacturing Decision-Makers

WRS addresses essential priorities across key roles:

• Manufacturing & Process Engineers: Faster cycle times, improved throughput, stronger uniformity across complex parts.

• Quality Leaders: Repeatable, reliable results that support quality assurance and reduce defect rates.

• Medical, Aerospace & Semiconductor Firms: Contamination control and sub-micron cleanliness for sensitive components.

• Facilities & Sustainability Managers: Lower resource consumption and reduced chemical waste aligned with environmental objectives.

As industries face increasing pressure to reduce energy use, minimize waste, and maintain rigorous product cleanliness standards, Kaijo’s Water Resonance System offers a compelling, timely solution.

About Kaijo Corporation

Kaijo is a global leader in advanced ultrasonic cleaning systems, serving the semiconductor, aerospace, automotive, medical device, and electronics manufacturing sectors. With decades of engineering expertise, Kaijo delivers precision cleaning technologies designed to improve efficiency, reliability, and sustainability in modern production environments.

Michael Danese

Kaijo Shibuya America Inc.

+1 408-675-5575

email us here

Visit us on social media:

LinkedIn

Facebook

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.