NordSpace Awarded $1M from Canadian Space Agency to Advance Domestic Additive Manufacturing for Rocket Propulsion

Canada’s push for responsive, scalable space launch capabilities gains momentum with new funding into NordSpace’s new Advanced Manufacturing for Aerospace Lab

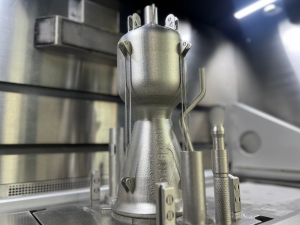

The multi-material advanced manufacturing project for space propulsion harnesses breakthrough methods, such as novel functionally-graded materials and innovative multi-alloy composites, to optimize rocket engine design, fabrication, and testing. NordSpace will partner with leading Canadian research institutes and small businesses to produce next-generation regeneratively cooled liquid engines, validated through rigorous hot-fire test campaigns and positioned for flight qualification and commercial scale-up.

“Canada’s growing demand for responsive and cost-effective medium-lift space launch requires continuous investment in disruptive manufacturing technologies that shorten development cycles, boost reliability, and reduce production costs,” said Rahul Goel, CEO and Founder of NordSpace. “This CSA STDP award represents a crucial step for NordSpace and the Canadian aerospace sector. These breakthroughs directly benefit Canada’s industrial base, making our factories and labs more competitive and efficient while accelerating the time to market for our Hadfield and Garneau engine lines. Faster development, robust design, and manufacturing leadership are critical for Canada to drive commercial success and, above all, to secure Canada’s place on the global stage as a sovereign provider of launch solutions for our country and our Allies.”

By advancing the science and application of functionally-graded materials and additive manufacturing, NordSpace is not just innovating but laying the foundation for new highly-skilled jobs in engineering, robotics, materials science, and advanced manufacturing. NordSpace’s STDP project will directly support 15 highly-skilled positions across the project partners, and lead to dozens of new engineering and manufacturing positions following successful completion of the project and start of engine commercialization. In addition to fueling job creation, the initiative will deliver cutting-edge additive manufacturing know-how and intellectual property to Canada’s aerospace supply chain, enabling technology transfer and economic benefits across adjacent sectors like aviation, energy, and automotive.

This announcement builds on NordSpace’s Advanced Manufacturing for Aerospace Lab launched earlier this year with Ontario Centre for Innovation support. The AMA Lab has already accelerated the design of NordSpace’s 3D-printed Hadfield engines and enhanced development cycles through AI-driven design methodologies and direct validation at the company’s test range. Now, this new CSA STDP project will go further into production methods for these advanced rocket engines.

For more information on NordSpace’s AMA Lab or to explore partnership opportunities, visit www.nordspace.com or contact contact@nordspace.com. NordSpace will also present updates on this initiative at the Canadian Space Launch Conference on May 5, 2026 in Ottawa.

About NordSpace

NordSpace, established in 2022, develops vertically integrated solutions for responsive orbital launch vehicles, spaceports, turn-key satellites, and mission-critical software systems. 100% designed, built, and flown in Canada to go from anywhere on Earth to anywhere in space. The company’s mission is to advance life on Earth through space, delivering innovation, jobs, national security, and sovereignty.

Media Inquiries:

Team NordSpace, NordSpace Corp., contact@nordspace.com

Team NordSpace

NordSpace Corp.

email us here

Visit us on social media:

LinkedIn

Instagram

YouTube

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.