A heterointerface strategy pushes infrared microbolometers beyond 125 °C

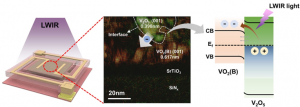

FAYETTEVILLE, GA, UNITED STATES, February 3, 2026 /EINPresswire.com/ -- Long-wave infrared (LWIR) microbolometers are essential for thermal imaging in harsh environments, yet their performance typically degrades at elevated temperatures. This study introduces a nanocomposite thermistor that combines two vanadium oxide phases to overcome this limitation. By engineering a heterointerface between conductive VO₂(B) and insulating V₂O₅, the material sustains high temperature sensitivity and fast infrared response even at 125 °C. The composite leverages interfacial charge transfer and photo-electron effects to maintain strong resistance changes under LWIR illumination. As a result, microbolometers based on this nanocomposite exhibit stable responsivity, low noise, and rapid response at temperatures where conventional materials fail, opening new possibilities for reliable thermal sensing in extreme operating conditions.

Thermal imaging systems play a growing role in applications such as autonomous driving, industrial monitoring, and outdoor surveillance, where sensors must operate reliably under high ambient temperatures. Microbolometers, which detect infrared radiation through temperature-induced resistance changes, are attractive because they are lightweight and uncooled. However, commonly used thermistor materials suffer from rapidly decreasing temperature coefficients of resistance (TCR) above about 80 °C. At higher temperatures, photothermal effects weaken, carrier dynamics change, and thermal noise increases, leading to reduced sensitivity. These challenges highlight a fundamental bottleneck in extending long-wave infrared (LWIR) microbolometer performance to harsh environments, and due to these limitations, it becomes necessary to explore new material strategies that enable stable, high-temperature infrared detection.

Researchers from the Korea Institute of Science and Technology and collaborating universities report a new oxide nanocomposite that enables LWIR microbolometers to operate reliably at temperatures up to 125 °C. Published (DOI: 10.1016/j.esci.2025.100428) online in January 2026 in eScience, the study demonstrates that a VO₂(B)/V₂O₅ composite thin film fabricated at low temperatures delivers high temperature sensitivity, strong infrared responsivity, and fast response times under extreme heat. The work addresses a long-standing barrier in uncooled thermal imaging and provides a materials-level solution compatible with existing microbolometer fabrication processes.

The researchers designed a nanocomposite thermistor by embedding nanoscale V₂O₅ grains within a VO₂(B) matrix using a low-temperature sputtering process below 300 °C. Structural and spectroscopic analyses confirmed the coexistence of the two oxide phases and the formation of well-defined heterointerfaces. These interfaces play a central role in the device physics. Under LWIR illumination, electrons trapped in defect-related states of V₂O₅ are photo-excited and transferred into the narrower-bandgap VO₂(B), enhancing carrier density and conductivity beyond what is achievable through conventional photothermal effects alone.

Electrical measurements showed that the composite achieves a high TCR of about 2.19 %/K at room temperature and retains a value of 1.19 %/K at 125 °C, outperforming single-phase vanadium oxide films. Importantly, the TCR decreases much more gradually with temperature, enabling stable operation across a wide thermal range. When integrated into suspended microbolometer devices, the nanocomposite delivered responsivities of several kilovolts per watt and response times as short as ~0.72 ms at 125 °C. Noise measurements further revealed exceptionally low noise voltages, leading to detectivities that remain high or even improve at elevated temperatures. Together, these results demonstrate that interfacial photo-electron effects can compensate for thermal degradation and fundamentally extend microbolometer performance into high-temperature regimes.

According to the authors, the key advance lies in shifting the dominant detection mechanism from purely photothermal heating to interface-assisted carrier generation. By carefully balancing conductive and insulating oxide phases, the material supplies additional free carriers precisely when thermal effects would otherwise suppress sensitivity. This interface-driven approach not only stabilizes temperature-dependent resistance but also accelerates device response under infrared illumination. The researchers emphasize that achieving this performance with a low-temperature fabrication process is particularly important, as it allows direct integration with existing readout circuits without compromising device reliability or manufacturability.

High-temperature-stable microbolometers could significantly expand the use of thermal imaging in real-world environments. For autonomous vehicles, sensors that maintain sensitivity at 125 °C can operate reliably under direct sunlight, engine heat, and enclosed housings without active cooling. Industrial inspection systems may also benefit from robust infrared detectors capable of monitoring furnaces, pipelines, and power equipment. More broadly, the demonstrated heterointerface strategy offers a general framework for designing next-generation thermistor materials that combine thermal stability with fast, low-noise infrared response. This work suggests that interface engineering, rather than bulk material substitution alone, may be the key to advancing uncooled infrared sensing technologies.

References

DOI

10.1016/j.esci.2025.100428

Original Source URL

https://doi.org/10.1016/j.esci.2025.100428

Funding Information

This work was supported in part by the Nano·Material Technology Development Program through the National Research Foundation of Korea (NRF) funded by Ministry of Science and ICT (No. RS-2023-00237827), in part by a National Research Foundation of Korea (NRF) grant funded by the Korean government Ministry of Science and ICT (MSIT) (No. RS-2025-00520713), and in part by the Korea Institute of Science and Technology Institutional Program (No. 2E33542).

Lucy Wang

BioDesign Research

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.