Self-healing transparent coating fights bacteria and repairs itself within minutes

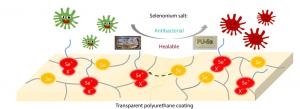

GA, UNITED STATES, December 19, 2025 /EINPresswire.com/ -- Imagine a phone screen or marine sensor that repairs scratches on its own and prevents bacterial buildup—without losing clarity. This study introduces a transparent polyurethane coating empowered by dynamic selenonium salts, giving it the rare ability to heal damage when heated and simultaneously stop bacterial growth. Once scratched, the coating can recover its smooth surface within minutes under moderate heat, and its clarity remains comparable to bare glass. Even after recycling or seawater immersion, the coating maintains transparency, structure, and antibacterial function. The work suggests a new route toward long-lasting protective films for devices exposed to wear, moisture, and microbial contamination.

Polyurethane coatings protect cars, ships, electronics, and public-touch surfaces, but real-world use brings scratches, fouling, and microbial attachment—slowly clouding transparency and weakening surfaces. Many self-healing films rely on microcapsules that work only once, while others sacrifice transparency or lack antibacterial capability. Meanwhile, marine environments and medical settings urgently need coatings that resist bacteria without leaching chemicals. A single material that is transparent, healable, antibacterial, and reprocessable has long been considered difficult to achieve, as improving one function often compromises another. Because of these unresolved conflicts, researchers sought a new chemistry to make coatings both durable and biologically defensive.

A team from Jiangsu University of Technology, Soochow University, and Ghent University reported (DOI: 10.1007/s10118-025-3414-7) on October 11, 2025, in Chinese Journal of Polymer Science that they have engineered a transparent, self-healing polyurethane coating strengthened by dynamic selenonium salts. The material not only repairs scratches under heat, but also disrupts bacterial cell membranes—offering long-term clarity and cleanliness. The coating maintained performance after seawater soaking and recycling, pointing to a practical solution for devices and surfaces that face daily wear.

The researchers embedded selenonium salts into a polyurethane network using a one-pot synthesis and thermal curing strategy. This dynamic chemistry enabled polymer chains to rearrange under heat, giving the coating vitrimer-like reprocessability while staying robust at room temperature. When scratched, PU2-C7 coatings healed visibly within 1 hour at 140 °C, and with slight pressure, recovery time shortened to ~20 minutes. Even after multiple cut-and-remold cycles, the films preserved chemical structure and mechanical behavior.

Antibacterial tests revealed striking results: selenonium-containing samples dramatically inhibited E. coli and S. aureus growth, with high-loading PU3-C7 nearly eliminating colonies. SEM images showed ruptured bacterial membranes, indicating a contact-killing mechanism. Optical measurements confirmed ~90–91% light transmittance, comparable to bare glass, and the coating remained clear after two weeks of simulated seawater immersion with minimal swelling. Pencil hardness reached 1H and adhesion was rated 4B–5B, meeting standards for protective coatings on devices and marine windows.

“This coating behaves like a living surface—it can recover from damage and defend itself against bacteria,” the authors explained. “The key lies in the dynamic selenonium chemistry, which allows the polymer network to reorganize during healing while keeping the surface hostile to microbes.” They added that maintaining transparency and mechanical stability after repeated recycling demonstrates the coating’s promise in durable and sustainable material design.

The technology could benefit phone screens, touch panels, underwater lenses, public facilities, medical devices, and ship equipment, where scratches and microbial contamination are daily challenges. Its high clarity means it can coat optical components without image loss, while recyclability supports circular material design. With further scale-up, long-term weathering tests, and flexibility tuning, the coating may help reduce maintenance costs and biofouling in marine or healthcare environments. The work opens the door to next-generation coatings that stay clean, clear, and repairable throughout their lifetime.

DOI

10.1007/s10118-025-3414-7

Original Source URL

https://doi.org/10.1007/s10118-025-3414-7

Funding information

This work was financially supported by the National Natural Science Foundation of China (Nos. 21971177 and 52503155), Natural Science Foundation of the Jiangsu Higher Education Institution of China (No. 22KJA150004), China Scholarship Council (No. 202206920034), Research Foundation Flanders (FWO) (Application 1S34725N), Priority Academic Program Development (PAPD) of Jiangsu Higher Education Institutions, Jiangsu Key Laboratory of Advanced Functional Polymers Design and Application, Soochow University, Suzhou Key Laboratory of Macromolecular Design and Precision Synthesis, and Program of Innovative Research Team of Soochow University. This project also received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 Research and Innovation Program 101021081 (ERC-AdG-2020, CiMaC-project).

Lucy Wang

BioDesign Research

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.