Pressure-Controlled Vacuum Sealers - Top Global Industry Trends in 2026

The USA market for pressure-controlled vacuum sealers is expected to grow at a CAGR of 7.7%, driven by packaging compliance in medical and electronics sectors.

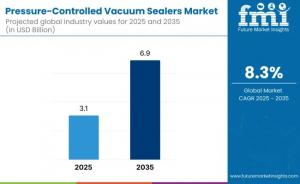

NEWARK, DE, UNITED STATES, November 20, 2025 /EINPresswire.com/ -- The pressure-controlled vacuum sealers market is entering a decade of accelerated modernization, projected to grow from USD 3.1 billion in 2025 to USD 6.9 billion by 2035, achieving a 2.2x expansion. This translates to a total revenue increase of USD 3.8 billion throughout the forecast period and a robust 8.3% CAGR, underscoring the rising global shift toward high-integrity, contamination-free packaging solutions.

As industries pivot toward stricter hygiene standards, extended shelf-life requirements, and product sterility assurance, pressure-controlled vacuum sealing technology has become indispensable across food processing, pharma manufacturing, medical device packaging, electronics assembly, and industrial components handling.

Discover Market Opportunities – Get Your Sample of Our Industry Overview Today!

https://www.futuremarketinsights.com/reports/sample/rep-gb-23240

Quick Market Highlights (2025–2035)

• 2025 Market Value: USD 3.1 billion

• 2035 Market Value: USD 6.9 billion

• Forecast CAGR: 8.3%

• Leading Segment in 2025: Single chamber systems (43.8% share)

• Fastest-Growing Region: Europe (UK leading with 9.2% CAGR)

• Top Manufacturers: Avid ARMOR, VAC Master, AmeriVacS Manufacturing, Inc., PAC Machinery, Bernhardt SAS, Boss Vakuum, PlexPack Corporation.

Strong Growth Momentum Driven by Dual-Phase Market Expansion

The decade can be divided into two distinct growth phases:

2025–2030: Value Creation Driven by Precision Packaging

The market grows from USD 3.1 billion to USD 4.6 billion, contributing USD 1.5 billion (39.5% of total decade growth).

This early-stage expansion is powered by:

• Increasing demand for premium food packaging, especially in meats, seafood, and ready-to-cook products

• Rising adoption in aerospace and medical device manufacturing, where pressure precision is crucial

• Growth of bench-top and chamber sealers with programmable pressure settings

2030–2035: Automation and Smart Packaging Lead

The market rises from USD 4.6 billion to USD 6.9 billion, adding USD 2.3 billion (60.5% of decade growth).

Key growth drivers include:

• Integration into automated vacuum sealing lines

• Adoption across pharmaceutical serialization and high-value electronics

• High penetration of IoT-enabled, software-integrated sealing systems

• Transition toward recyclable barrier materials compatible with modern sealing mechanisms

Market Evolution: 2020–2024 Set the Foundation

From USD 2.1 billion in 2020 to USD 2.8 billion in 2024, growth was driven by hardware-focused adoption in:

• Food processing

• Pharmaceuticals

• Medical device packaging

During this period, equipment manufacturers dominated 70% revenue share, led by brands such as:

• Avid ARMOR

• VAC Master

• Nesco

• AmeriVacS Manufacturing, Inc.

Digital modules and automation were considered secondary add-ons, and service-based revenue (calibration, seal testing) contributed less than 10%.

Between 2025 and 2035, however, sensor-based diagnostics, cloud integration, and aftermarket service models will exceed 40% of global revenue, redefining competitive differentiation.

Top Investment Segments: Where the Market Is Heading

The market is segmented by chamber type, pressure control, sealing type, application, end-use industry, and region, offering multi-layered growth opportunities.

1. Single Chamber Systems Lead (43.8% in 2025)

These systems gain traction due to:

• Compact design

• Lower operating cost

• High vacuum precision

• Suitability for small–mid scale processors

• Rising adoption in specialty food processing and pharma packaging

2. Food Processing Dominates End-Use (50.4% in 2025)

Driven by demand for:

• Shelf-life extension

• Oxidation reduction

• Safety compliance

• MAP-based packaging

HACCP-compliant food plants increasingly invest in advanced vacuum sealing systems for throughput enhancement and quality control.

3. Digital Pressure Programming Takes the Lead (41.3% in 2025)

Manufacturers prefer programmable vacuum cycles because they:

• Reduce operator dependency

• Offer consistent sealing

• Support automated production

• Enable multi-recipe storage and traceability

4. Double Seal Format Tops Sealing Type (46.2% in 2025)

Favored for:

• Strong structural integrity

• Higher resistance to oxygen/moisture ingress

• Reduced leakage risks

Ideal for pharmaceuticals, electronics, and industrial food packaging.

5. Perishable Goods Lead Applications (42.1% in 2025)

Due to increasing needs for:

• Microbial control

• Moisture and oxygen management

• Cold chain compatibility

• Premium-grade food preservation

What’s Driving the Market?

Key Growth Drivers

• Rising global demand for extended shelf life in food

• Growth in pharmaceutical sterile packaging

• Increasing adoption across semiconductor and electronics manufacturing

• Expanding use of MAP systems

• Need for clean-label, contamination-free packaging

Restraints

• High capital expenditure on sophisticated vacuum systems

• Calibration and maintenance complexity

• Skilled operator requirement in regulated industries

Market Trends

• IoT-enabled vacuum sealers with real-time pressure feedback

• Multi-recipe programmable sealing systems

• Touchscreen HMIs, audit trails, and cloud data logging

• Integration with robotic automation and QMS systems

Regional and Country-Level Insights

CAGR by Select Countries (2025–2035)

• UK: 9.2%

• India: 9.1%

• Japan: 8.7%

• Germany: 8.3%

• USA: 7.7%

• South Korea: 8.2%

• China: 8.1%

United States (7.7% CAGR)

Driven by:

• Medical device sterilization demand

• CFR Part 11–compliant sealing processes

• Electronics moisture-resistant packaging

United Kingdom (9.2% CAGR)

Growth led by:

• Biopharma production

• Diagnostic exports

• EU Annex 1 compliant sealing solutions

India (9.1% CAGR)

Fueled by:

• Food exports

• Pharma GMP compliance

• Cost-effective digital sealers from local manufacturers

China (8.1% CAGR)

Growth influenced by:

• Industrial-scale electronics manufacturing

• Cleanroom packaging standards

• Semi-automated sealing line integration

Subscribe for Year-Round Insights → Stay ahead with quarterly and annual data updates – https://www.futuremarketinsights.com/checkout/23240

Competitive Landscape

The market remains moderately fragmented, hosting players from consumer-grade brands to advanced industrial sealing specialists.

Leading companies include:

• PAC Machinery

• Bernhardt SAS

• Boss Vakuum

• Avid ARMOR

• AmeriVacS Manufacturing, Inc.

• VAC Master

• PlexPack Corporation

Product innovation revolves around:

• Precision pressure sensors

• Double sealing technology

• HACCP/ISO-certified sealing modules

• MAP and moisture-sensitive packaging compatibility

Key Recent Developments

• 2024: PAC Machinery launches its PVT Plus MED at PACK EXPO East

• June 2025: Avid Armor introduces A100 GEN 2 with advanced suction and pulse sealing features

Why FMI: https://www.futuremarketinsights.com/why-fmi

Have a Look at Related Research Reports on the Packaging Domain:

Magnetic Tape Market https://www.futuremarketinsights.com/reports/magnetic-tape-market

Fusion Bag Market https://www.futuremarketinsights.com/reports/fusion-bag-market

Containerboard Market https://www.futuremarketinsights.com/reports/containerboard-market

Pressure Sensitive Labeling Machine Market https://www.futuremarketinsights.com/reports/pressure-sensitive-labeling-machine-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.