Bearing Steel Market is Predicted to Reach USD 8.9 Billion by 2035, Driven by Demand for Long-Lasting Steel Solutions

UK bearing steel market grows 3.0% CAGR, driven by aerospace, rail, and precision tooling demand, with focus on quality, durability, and traceable supply.

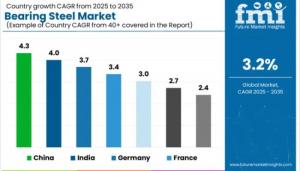

NEWARK, DE, UNITED STATES, August 12, 2025 /EINPresswire.com/ -- The global bearing steel market is on track to grow from USD 6.5 billion in 2025 to USD 8.9 billion by 2035, marking a steady 3.2% CAGR over the next decade. With applications spanning automotive, aerospace, machinery, energy, and construction, bearing steel is proving to be a cornerstone material for industries that demand exceptional hardness, fatigue strength, and wear resistance.

For manufacturers, this forecast signals more than just market expansion it represents a tangible opportunity to integrate higher-performance, longer-lasting steel grades that can withstand the most demanding operational environments, ultimately supporting product innovation, lifecycle value, and cost efficiency.

Why the Bearing Steel Market Is Expanding

The market’s growth is fueled by the increased deployment of advanced machinery, rising automotive production, and the ongoing shift toward electric vehicles and renewable energy systems. These applications place extreme demands on bearings, requiring steel with unmatched precision, dimensional stability, and fatigue life.

Advancements in steel processing, heat treatment, and metallurgical refinement are enabling manufacturers to produce components that last longer, perform more reliably, and reduce downtime a competitive advantage in industries where efficiency is paramount.

High Carbon Chromium Steel: The Performance Leader

The high carbon chromium segment dominates the product landscape with a 42.7% market share. Known for superior hardness and high wear resistance, this grade is the preferred choice for automotive, heavy machinery, and wind energy applications. Its dimensional stability and compatibility with advanced heat treatments make it indispensable for bearings operating under high loads and rotational speeds.

For OEMs and component suppliers, adopting high carbon chromium steel means reduced replacement intervals, lower warranty claims, and improved performance consistency, directly contributing to profitability and customer satisfaction.

Ball Bearings: Driving Precision and Efficiency

Holding 39.1% of the application market, ball bearings are the lifeblood of countless rotating systems. From electric motors to industrial machinery, these components require steel that guarantees low friction, high precision, and minimal maintenance.

As industries embrace automation, miniaturization, and higher energy efficiency standards, demand for advanced bearing steels in ball bearing production is expected to rise sharply. Manufacturers leveraging this material can differentiate products with enhanced speed capabilities, longer service life, and reliability under varying load conditions.

Automotive Industry: The Largest End-Use Driver

With a 48.6% market share, the automotive sector remains the most influential consumer of bearing steel. Bearings are critical to engines, transmissions, wheel hubs, and electric drivetrains, where they must endure elevated temperatures, continuous stress cycles, and exacting efficiency requirements.

The transition toward vehicle electrification and higher OEM performance standards underscores the need for steels that deliver superior fatigue resistance, thermal stability, and compliance with evolving regulations. For manufacturers, aligning with these demands is essential for securing long-term supply contracts and maintaining global competitiveness.

Market Challenges and How Manufacturers Can Overcome Them

• Regulatory Compliance Pressures: Global quality standards for bearing steel are tightening, increasing the burden of testing for fatigue resistance, cleanliness, and dimensional stability. Manufacturers that invest in in-house labs, precision inspection systems, and strategic partnerships can not only meet compliance requirements but also position themselves as premium suppliers in a market where quality is a differentiator.

• Raw Material Cost Volatility: Price fluctuations in high-purity iron, chromium, and alloying elements are impacting profitability. Forward-looking companies are optimizing procurement strategies, refining processing efficiency, and building resilient supply chains to manage costs without compromising steel quality.

Demand Hotspots Across Sectors

From electric vehicle gearboxes to wind turbine bearings, demand is surging for steel grades offering durability, minimal maintenance, and thermal stability. Industrial machinery, mining, and railway sectors are also increasing adoption, creating diverse revenue streams for producers who can deliver tailored compositions, surface finishes, and corrosion resistance.

Technology Trends Shaping the Future

Manufacturers adopting vacuum degassing, electroslag remelting, and precision thermo-mechanical treatments are gaining a competitive edge. These methods enhance fatigue resistance, grain structure control, and dimensional accuracy, while digital quality monitoring enables real-time defect detection.

Such innovations are critical for meeting the tight tolerances of aerospace bearings, high-speed rail components, and robotics, all sectors where downtime is costly and failure is unacceptable.

Regional Growth Insights

• China (4.3% CAGR): Expanding specialty steel capacity, driven by railway, automotive, and industrial gearbox demand.

• India (4.0% CAGR): Growth in electric motor production, railway applications, and agricultural machinery.

• Germany (3.7% CAGR): Precision grades for wind turbines, robotics, and high-performance automotive components.

• UK (3.0% CAGR): Aerospace, rail rolling stock, and precision tooling applications favor fine-grain, certified grades.

• USA (2.7% CAGR): Mature but stable demand for defense, aerospace, and heavy industrial applications with strict quality standards.

Competitive Landscape

Industry leaders such as SKF Group, Timken Company, JTEKT Corporation, Nippon Steel Corporation, Schaeffler Group, Ovako Group, TATA Steel, and Steel India are shaping the market through vertical integration, metallurgical innovation, and customer-specific alloy development.

Notably, on July 10, 2024, SKF and voestalpine unveiled the world’s first bearing prototype made from hydrogen direct reduced iron (H-DRI) steel, combining low-carbon manufacturing with uncompromised performance a landmark moment for sustainable steel production.

Request Bearing Steel Market Draft Report:

https://www.futuremarketinsights.com/reports/sample/rep-gb-22881

For more on their methodology and market coverage, visit https://www.futuremarketinsights.com/about-us.

The Manufacturer’s Opportunity

The next decade presents a clear choice for manufacturers: adapt to higher performance, stricter compliance, and sustainability demands, or risk falling behind. Bearing steel is not just a commodity; it is a performance enabler.

By partnering with advanced steel producers and integrating premium grades, innovative processing, and robust quality systems, manufacturers can extend product life, reduce operating costs, and strengthen their competitive position in a global marketplace that values reliability and durability above all else.

Related Insights from Future Market Insights (FMI)

High Carbon Bearing Steel Market - https://www.futuremarketinsights.com/reports/high-carbon-bearing-steel-market

Steel Market - https://www.futuremarketinsights.com/reports/steel-market

Editor's Note:

The bearing steel market is set for steady growth, driven by rising demand in automotive, industrial machinery, and energy sectors. Advancements in metallurgy and manufacturing are enhancing durability, load capacity, and efficiency of bearings. As global infrastructure and transportation projects expand, bearing steel remains a critical material ensuring long-term performance and reliability.¬¬¬¬¬

Rahul Singh

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.