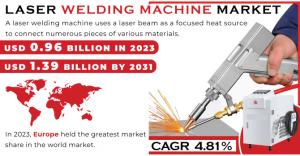

Laser Welding Machine Market Would Rocket Up to at USD 1.39 Billion by 2031

Laser Welding Machine Market Set for Robust Growth Driven by Technological Advancements and Increasing Demand in Manufacturing

TEXES, AUSTIN, UNITED STATES, May 27, 2024 /EINPresswire.com/ -- The global laser welding machine market is poised for significant growth in the coming years, driven by rapid technological advancements, increasing adoption in various manufacturing sectors, and the rising demand for precision welding solutions. Laser Welding Machine Market size was valued at USD 0.96 Bn in 2023 and is expected to reach USD 1.39 Bn by 2031 and grow at a CAGR of 4.81% over the forecast period 2024-2031.Download Sample Copy of Report: https://www.snsinsider.com/sample-request/1151

Top Key Players:

Emerson Electric Company

IPG Photonics

O.R. Lasertechnologie

TRUMPF Group

Amada Miyachi Co., Ltd

FANUC Robotics

Golden Laser

GSI Group, Inc.

JENOPTIK AG.

LaserStar Technologies Corporation.

Summary

The laser welding machine market is experiencing a surge in demand, fueled by its growing application in automotive, aerospace, electronics, and medical device manufacturing. The ability of laser welding machines to provide high precision, speed, and efficiency in welding operations is making them a preferred choice across industries. The market is set to expand significantly, supported by technological innovations and increasing investments in advanced manufacturing technologies.

Market Analysis

The market analysis indicates that North America and Europe are the leading regions in terms of adoption of laser welding machines, owing to their advanced industrial infrastructure and high focus on technological innovation. The Asia-Pacific region is expected to witness the highest growth rate, driven by rapid industrialization, expanding manufacturing base, and increasing government initiatives to promote high-tech manufacturing.

Market Segmentation:

By Technology

Fiber Laser Welding Machine

Solid-State Laser Welding Machine

Co2 Laser Welding Machine

By End-user

Automotive

Electronics

Medical

Jewelry Industry

Tool and Mold-Making

Others

Enqiry Before buy: https://www.snsinsider.com/enquiry/1151

Market Dynamics

Opportunities

Technological Advancements: Continuous innovations in laser technology, such as the development of fiber lasers and hybrid laser-arc welding, are creating new opportunities for market growth. These advancements enhance the efficiency and capabilities of laser welding machines, making them suitable for a broader range of applications.

Growing Demand in Emerging Markets: Rapid industrialization and urbanization in emerging economies present significant opportunities for market expansion. Increased manufacturing activities in these regions are driving the demand for advanced welding technologies.

Expansion in Medical Device Manufacturing: The growing medical device industry, driven by an aging population and increasing healthcare expenditures, is a major opportunity for the laser welding machine market. Precision welding is critical in the manufacturing of medical devices, and laser welding machines are well-suited for this application.

Market Drivers

Precision and Efficiency: Laser welding machines offer unmatched precision and efficiency, making them ideal for high-volume production environments. Their ability to produce high-quality welds with minimal distortion and heat-affected zones is a key driver of market growth.

Increasing Automation in Manufacturing: The trend towards automation in manufacturing processes is boosting the demand for laser welding machines. These machines can be easily integrated into automated production lines, enhancing productivity and reducing labor costs.

Environmental and Safety Benefits: Laser welding is a cleaner and safer process compared to traditional welding methods. It produces fewer emissions and requires less post-weld processing, which is driving its adoption in industries with strict environmental and safety regulations.

Key Factors

Cost-Effectiveness: Despite the high initial investment, laser welding machines are cost-effective in the long run due to their low maintenance requirements, high operational speed, and reduced material wastage.

Versatility: The versatility of laser welding machines to work with a wide range of materials, including metals, plastics, and composites, makes them highly valuable across various industries.

R&D Investments: Increased investments in research and development are leading to the creation of more advanced and efficient laser welding solutions, further propelling market growth.

Buy Complete Report: https://www.snsinsider.com/checkout/1151

Challenges

High Initial Investment: The high cost of laser welding machines and the associated setup costs can be a significant barrier for small and medium-sized enterprises (SMEs).

Skilled Workforce Requirement: The operation of laser welding machines requires a skilled workforce. The shortage of trained professionals can hinder the adoption of this technology in certain regions.

Technical Limitations: Despite advancements, there are still technical limitations in laser welding, such as difficulties in welding reflective materials and thickness limitations, which can restrict its application in some areas.

Akash Anand

SNS Insider | Strategy and Stats

+1 415-230-0044

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Instagram

YouTube

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.