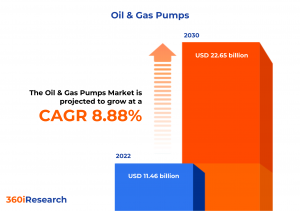

Oil & Gas Pumps Market worth $22.65 billion by 2030, growing at a CAGR of 8.88% - Exclusive Report by 360iResearch

The Global Oil & Gas Pumps Market to grow from USD 11.46 billion in 2022 to USD 22.65 billion by 2030, at a CAGR of 8.88%.

PUNE, MAHARASHTRA, INDIA , December 5, 2023 /EINPresswire.com/ -- The "Oil & Gas Pumps Market by Type (Non-Submersible Pumps, Submersible Pumps), Pump (Centrifugal Pump, Cryogenic Pump, Positive Displacement Pump), Category, Application - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Oil & Gas Pumps Market to grow from USD 11.46 billion in 2022 to USD 22.65 billion by 2030, at a CAGR of 8.88%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/oil-gas-pumps?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Oil and gas pumps are a crucial component in the petroleum industry, serving as the mechanical devices responsible for moving various types of fluids, including natural gas, crude oil, and their derivatives, through pipelines, refining processes, and storage facilities. These pumps are designed to handle the high pressure, temperature variances, and corrosive nature of the fluids encountered in the extraction, transportation, refining, and distribution stages of oil and gas operations. Increased investments in the oil & gas industry's upstream sector, expansion of refineries, and rising demand for petroleum products are significant drivers for the growth of oil and gas pumps. Furthermore, the shift towards renewable energy sources has compelled the industry to improve the operational efficiency of pumps, thereby spurring innovation and growth. However, limitations associated with decreased flow rates, reduced head pressures, and increased power consumption impede the widespread adoption of oil and gas pumps. Additionally, cases of product recalls caused by failures of components of oil and gas pumps further raise concerns about the reliability and safety of the pumps. To circumvent technical challenges and failures of oil and gas pumps, key players are exploring advancements in smart and automated pump technologies that enable predictive maintenance, increased operational efficiency, and minimized downtime. Additionally, the integration of IoT in pump systems for better monitoring and data analysis offers significant opportunities for growth.

Pump: Rising number of centrifugal pumps in expanding oil and gas projects

Centrifugal pumps are the most commonly used oil and gas pump types. They operate using rotational energy, typically from an engine or electric motor, to move fluids through a system. These pumps are preferred when a uniform and continuous flow is required. They are notably efficient for the transfer of light oils and petrochemicals. Cryogenic pumps are utilized in applications involving extremely low temperatures, typically for the movement of liquefied natural gas (LNG) and other cryogenic fluids. Positive displacement (PD) pumps are vital for handling high-viscosity fluids or where precise volumetric flow control is required. They function by trapping a fixed amount of fluid and then forcing (displacing) that trapped volume into the discharge pipe. A progressive cavity pump (PCP) is a type of positive displacement pump commonly used in the oil and gas industry to handle viscous and multiphase fluids as well as abrasive and corrosive substances. Reciprocating pumps are another type of positive displacement pump that operates on the principle of a piston or plunger moving back and forth within a cylinder, which displaces the fluid and creates a variable flow under high pressure. Rotary gear pump facilitates the smooth flow of viscous fluids, and screw pumps can be used with versatility flow rates, pressures, liquid types, and viscosities.

Type: Advancements and initiatives to improve the performance of submersible pumps

Non-submersible pumps, also known as surface pumps, operate with the pump and motor located above ground level. These pumps are widely preferred for tasks where direct access to the pumped fluid is available, and there is no requirement for the pump to be placed within the fluid reservoir. They are often used in crude oil transmission, refinery processes, and transportation of large volumes of fluids at relatively low pressures. Submersible pumps are fully immersed in the liquid being pumped and are well suited for applications requiring the pumping of liquid from below ground level, such as in offshore drilling rigs, underwater operations, and wells. They are typically used for deepwater drilling, artificial lift, and other operations that require high-pressure fluid movement from below ground.

Category: Dynamic pumps are preferred choice due to its efficiency and low maintenance in transferring large and diverse range of viscous volumes

Dynamic pumps, also known as kinetic pumps, transfer fluid by increasing the velocity of the fluid through an impeller. They are primarily used in applications where a high flow rate and lower pressure are required. They are suited for continuous operations and are commonly used for water supply, cooling, and fuel transfer systems in the oil and gas industry. Positive displacement pumps move fluid by trapping a fixed amount and forcing (displacing) that trapped volume into the discharge pipe. These pumps are ideal for applications requiring consistent flow rates regardless of fluid viscosity and pressure conditions. They are often selected for high-viscosity, high-pressure, and high-accuracy applications, such as in upstream oil and gas operations involving heavy crude or precise metering. The choice between dynamic and positive displacement pumps in the oil and gas sector primarily hinges on the specific fluid handling requirements. Dynamic pumps are favored for their efficiency in transferring large volumes of fluid at lower pressures, which is particularly useful for midstream and downstream operations. Positive displacement pumps, on the other hand, excel in upstream activities where higher pressures and precise volumetric flow management are necessary. When comparing maintenance needs, dynamic pumps typically require less routine service than positive displacement pumps due to having fewer moving parts. However, the latter's ability to handle a wider range of fluid types often outweighs the higher maintenance consideration in complex operations such as handling high-viscosity fluids or mixed-phase flows.

Application: Intended push towards using more sustainable pumping solutions with lower emissions

Downstream applications refer to the processing of crude oil into refined products, including the operation of refineries, petrochemical plants, and the distribution and sales of the final products. Pumps are crucial in downstream processing for transferring refined products, maintaining process flow, and handling multiple chemicals and fluids. Downstream users prioritize equipment that minimizes maintenance and operation costs while maximizing safety and ease of operation. Midstream applications primarily involve the transportation and storage of unrefined crude oil and refined products before they reach the downstream facilities. They include pipelines, terminals, and storage facilities. Pumps designed for the midstream sector are built to handle high-pressure, long-distance transport requirements. Reliability is of particular importance in these applications, as downtime can have significant implications on supply chains and can incur high costs. Upstream applications include the exploration, drilling, and production of crude oil and natural gas from onshore and offshore fields. Pumps in the upstream segment must withstand extreme conditions, as they are often employed in remote and harsh environments. Efficiency, rugged design, and dependability are key to ensuring continuous operation in the upstream sector.

Regional Insights:

The Americas region, particularly the US and Canada, is involved in product innovations for oil and gas pumps due to the presence of a robust technological sector. Additionally, the production and exploration activities drive the demand for robust pumping systems for extraction purposes. Modernization and expansion of pipeline infrastructure contribute to the rising need for oil and gas pumps within the region. Sustainability considerations and regulations pertaining to energy efficiency in the oil and gas industry have driven innovations in the European Union and led to highly energy-efficient oil and gas pumps. Furthermore, dependency on gas imports and the need for secure energy supplies are propelling the demand for gas pumps for storage and distribution. The presence of a robust and advanced oil and gas sector in the Middle East sectors drives demand for advanced oil and gas pumps. APAC region serves as a crucial manufacturing hub for oil and gas pumps due to the presence of a cost-effective labor force and expansive manufacturing facilities. A trend toward local production and supply chain enhancement is fostering the creation and growth of regional pump manufacturing capabilities.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Oil & Gas Pumps Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Oil & Gas Pumps Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Oil & Gas Pumps Market, highlighting leading vendors and their innovative profiles. These include ALFA LAVAL Corporate AB, Baker Hughes Company, Debem Srl, EBARA CORPORATION, Elliott Company, Flowserve Corporation, Gemmecotti Srl, Halliburton Energy Services, Inc., HYDROMASHSERVICE by HMS Group, Ingersoll Rand Inc., ITT Goulds Pumps, JEE Pumps, KSB SE & Co. KGaA, Nikkiso Co., Ltd., Rodelta Pumps International, Roto Pumps Ltd., Ruhrpumpen, Inc., Schmitt Kreiselpumpen GmbH & Co. KG, Sulzer Management Ltd., The Gorman-Rupp Company, Trillium Flow Technologies, and Xylem Inc..

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/oil-gas-pumps?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Oil & Gas Pumps Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Type, market is studied across Non-Submersible Pumps and Submersible Pumps. The Non-Submersible Pumps is projected to witness significant market share during forecast period.

Based on Pump, market is studied across Centrifugal Pump, Cryogenic Pump, and Positive Displacement Pump. The Positive Displacement Pump is further studied across Progressive Cavity Pump, Reciprocating Pump, Rotary & Gear pump, and Screw Pump. The Reciprocating Pump is further studied across Diaphragm Pump, Multi-Plunger Pump, and Piston Pump. The Centrifugal Pump is projected to witness significant market share during forecast period.

Based on Category, market is studied across Dynamic and Positive Displacement. The Positive Displacement is projected to witness significant market share during forecast period.

Based on Application, market is studied across Downstream, Midstream, and Upstream. The Midstream is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Americas commanded largest market share of 42.41% in 2022, followed by Europe, Middle East & Africa.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Oil & Gas Pumps Market, by Type

7. Oil & Gas Pumps Market, by Pump

8. Oil & Gas Pumps Market, by Category

9. Oil & Gas Pumps Market, by Application

10. Americas Oil & Gas Pumps Market

11. Asia-Pacific Oil & Gas Pumps Market

12. Europe, Middle East & Africa Oil & Gas Pumps Market

13. Competitive Landscape

14. Competitive Portfolio

15. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Oil & Gas Pumps Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Oil & Gas Pumps Market?

3. What is the competitive strategic window for opportunities in the Oil & Gas Pumps Market?

4. What are the technology trends and regulatory frameworks in the Oil & Gas Pumps Market?

5. What is the market share of the leading vendors in the Oil & Gas Pumps Market?

6. What modes and strategic moves are considered suitable for entering the Oil & Gas Pumps Market?

Read More @ https://www.360iresearch.com/library/intelligence/oil-gas-pumps?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.