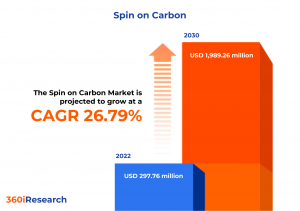

Spin on Carbon Market worth $1,989.26 million by 2030, growing at a CAGR of 26.79% - Exclusive Report by 360iResearch

The Global Spin on Carbon Market to grow from USD 297.76 million in 2022 to USD 1,989.26 million by 2030, at a CAGR of 26.79%.

PUNE, MAHARASHTRA, INDIA , December 4, 2023 /EINPresswire.com/ -- The "Spin on Carbon Market by Material Type (Hot-temperature spin on carbon, Normal-temperature spin on carbon), Application (Logic Devices, Memory Devices, Photonics), End User - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Spin on Carbon Market to grow from USD 297.76 million in 2022 to USD 1,989.26 million by 2030, at a CAGR of 26.79%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/spin-on-carbon?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Spin on Carbon is a specialized class of materials used predominantly in the semiconductor industry. SoC materials are carbon-based coatings that are applied to semiconductor wafers using a spin-coating technique. This process involves depositing a small amount of SOC material onto the wafer and then spinning the wafer at high speed to achieve a thin, uniform coating. The growing demand for more sophisticated chips for semiconductor production and the development of extreme ultraviolet lithography (EUV) in memory manufacturing increases the adoption of the spin-on carbon material. However, the high costs involved in developing and manufacturing SoC coatings due to sophisticated production requirements may hinder market growth. Nevertheless, advancement in SoC material formulations to cater to evolving industry needs is expected to create potential opportunities for the SoC market.

Application: Burgeoning utilization of SoC in power devices owing to its capability to endure high-energy plasma etches

Logic devices form the backbone of computational hardware comprising CPUs, microprocessors, and field-programmable gate arrays (FPGAs). These components rely heavily on cutting-edge fabrication techniques to continually shrink device geometries while increasing performance and efficiency. The preference for SoC materials here is driven by their ability to enable high-resolution patterning, which is essential for advanced node logic device manufacturing. Memory devices, including DRAM, SRAM, and flash memory, require SoC for the patterning of complex memory cell structures. These devices are critical for storage and data retrieval in electronics. SoC materials are used in memory devices for their compatibility with multi-patterning techniques necessary for high-density memory fabrication. In photonics, SoC is utilized to produce photonic integrated circuits (PICs), which harness light for data transmission, leading to faster and more energy-efficient communication systems. The need for SoC in photonics arises from its high etch selectivity that facilitates the creation of fine features without damaging underlying layers. Power devices such as MOSFETs, IGBTs, and diodes are crucial for managing power efficiency in electronic circuits. SoC materials in power devices are required for their thermal stability and aptitude to create robust isolation features necessary for high-power applications.

End User: Evolving utilization of spin on carbon material by integrated device manufacturers

Foundries are manufacturing facilities where casting is carried out, often to produce metal products, including iron, steel, and aluminum components. In the context of spin-on carbon, foundries may utilize this material within the manufacturing process of semiconductor wafers or metal casting molds to enhance the characteristics of the final product, such as its structural integrity or thermal stability. Integrated device manufacturers (IDM) design, manufacture, and sell semiconductor products. IDMs are involved in the entire product lifecycle from design to assembly and are deeply concerned with precision, scalability, and integration of advanced materials including spin on carbon in their production lines. OSATs are service providers for semiconductor companies, typically handling the final stages of semiconductor manufacturing, such as assembly, packaging, and testing. These entities are an essential link in the semiconductor supply chain, connecting wafer producers and electronic device manufacturers.

Material Type: Significant usage of hot-temperature spin on carbon (HTC) in high-temperature processes

Hot-temperature spin on carbon (HTC)materials is a specialized coating designed to withstand high thermal processes commonly required in semiconductor manufacturing. These materials are used as a hard mask during the patterning of features in semiconductor devices. They are necessary where high-temperature resistance is critical, for instance, during processes that involve high-temperature bakes and etches. Normal-temperature spin on carbon (NTC) materials is utilized as an underlayer in photolithography processes, suitable for environments that demand carbon hard masks but do not require the high-temperature resistance of HTC coatings. NTC formulations are designed to perform effectively under standard thermal conditions, usually up to 200°C, which is adequate for many semiconductor process flows. HTC is the preferred solution in high-temperature operations, offering stability and integrity, while NTC is adequate for less demanding processes, offering economic advantages and practicality for standard temperature ranges.

Regional Insights:

The Spin on Carbon (SoC) market is evolving in Americas region owing to the innovation with numerous patents reflecting pioneering work in material science and fabrication techniques. In addition, involvement in the research of advanced materials and collaborative initiatives between academia and industry are resulting in new applications and enhanced properties of carbon-based coatings, presenting a steady growth in the spin-on carbon market in this region. The EMEA region, including the European Union countries, the Middle East, and Africa, shows a dynamic and diverse market for spin-on carbon, driven by the region's stringent environmental regulations and commitment to high-quality manufacturing standards and the region has seen increased mobile penetration rates which may in the future translate to local developments in the consumer electronics manufacturing sector and subsequent demand for semiconductor materials. On the other hand, in Middle Eastern countries, investments in educational institutes and high-tech parks are opening up new avenues for research and development in the region. The Asia-Pacific region is witnessing growth in the Spin on Carbon market, characterized by a growing demand for consumer electronics that require high-grade semiconductors. This upsurge stimulates interest in advanced materials, such as spin on carbon, with government and private entities investing in semiconductor manufacturing capabilities.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Spin on Carbon Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Spin on Carbon Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Spin on Carbon Market, highlighting leading vendors and their innovative profiles. These include Applied Materials, Inc., Brewer Science, Inc., Dongjin Semichem Co., Ltd., DuPont de Nemours, Inc., HDC YoungChang, Hydraquip, INBRAIN Neuroelectronics SL, Irresistible Materials Ltd., JSR Micro Inc, Kayaku Advanced Materials, Inc., KOYJ CO.,LTD, Merck KGaA, Nano-C Inc., Pibond Oy, Samsung SDI Co., Ltd., Shin-Etsu Chemical Co., Ltd., and YCCHEM CO.,Ltd..

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/spin-on-carbon?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Spin on Carbon Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Material Type, market is studied across Hot-temperature spin on carbon and Normal-temperature spin on carbon. The Hot-temperature spin on carbon is projected to witness significant market share during forecast period.

Based on Application, market is studied across Logic Devices, Memory Devices, Photonics, and Power Devices. The Memory Devices is projected to witness significant market share during forecast period.

Based on End User, market is studied across Foundries, Integrated Device Manufacturers, and Outsourced Semiconductor Assembly & Test. The Integrated Device Manufacturers is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Europe, Middle East & Africa commanded largest market share of 37.27% in 2022, followed by Americas.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Spin on Carbon Market, by Material Type

7. Spin on Carbon Market, by Application

8. Spin on Carbon Market, by End User

9. Americas Spin on Carbon Market

10. Asia-Pacific Spin on Carbon Market

11. Europe, Middle East & Africa Spin on Carbon Market

12. Competitive Landscape

13. Competitive Portfolio

14. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Spin on Carbon Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Spin on Carbon Market?

3. What is the competitive strategic window for opportunities in the Spin on Carbon Market?

4. What are the technology trends and regulatory frameworks in the Spin on Carbon Market?

5. What is the market share of the leading vendors in the Spin on Carbon Market?

6. What modes and strategic moves are considered suitable for entering the Spin on Carbon Market?

Read More @ https://www.360iresearch.com/library/intelligence/spin-on-carbon?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.