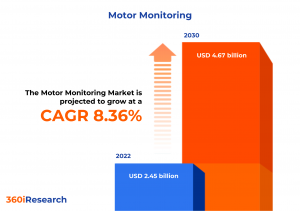

Motor Monitoring Market worth $4.67 billion by 2030, growing at a CAGR of 8.36% - Exclusive Report by 360iResearch

The Global Motor Monitoring Market to grow from USD 2.45 billion in 2022 to USD 4.67 billion by 2030, at a CAGR of 8.36%.

PUNE, MAHARASHTRA, INDIA , December 4, 2023 /EINPresswire.com/ -- The "Motor Monitoring Market by Technology (Current Signature Analysis, Electric Discharge Current Measurement, Motor Current Monitoring), Monitoring Process (Online Motor Monitoring, Portable Motor Monitoring), Offering, Deployment, End-Use - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Motor Monitoring Market to grow from USD 2.45 billion in 2022 to USD 4.67 billion by 2030, at a CAGR of 8.36%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/motor-monitoring?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Motor monitoring refers to the process of continuously analyzing the performance and condition of electric motors in industrial settings. It involves the use of various sensors and devices that collect data on parameters such as vibration, temperature, current, voltage, and power quality. This data is then analyzed to assess the health of the motor and predict potential failures before they occur. The integration of the Internet of Things (IoT) in industrial devices has allowed for more sophisticated and real-time monitoring capabilities. As industries look to reduce maintenance costs and prevent unplanned downtimes, demand for advanced monitoring increases. Stringent energy consumption and reliability standards encourage investment in efficient monitoring systems. However, the cost of setting up advanced monitoring systems can be a barrier for small to medium-sized enterprises (SMEs), and integration of new systems with existing equipment and processes can challenge companies and require specialized skills. Market players work on the development of wireless sensor networks for monitoring, which can reduce installation costs and enhance connectivity. They are also developing monitoring systems that consume less power and are themselves more sustainable.

Offering: Availability of automated alerting mechanisms that notify maintenance personnel about motor performance

Effective motor monitoring relies on a range of hardware components that work together to ensure continuous and reliable performance. These components include sensors, data acquisition systems (DAS), signal conditioners, data loggers, and communication systems. The data captured by hardware components are processed and analyzed using sophisticated software systems, which include data analysis software, diagnostic tools, asset management software, human-machine interface, reporting tools, and integration platforms. These are specialized components that assess the condition of the motor and predict its remaining useful life based on historical and real-time data.

Monitoring Process: Preference for online monitoring to prevent unscheduled downtime and prolonging motor lifespan

Online motor monitoring is a continuous surveillance process wherein the performance and condition of electric motors and their components are tracked in real time. This method provides immediate insights into operational parameters such as current, voltage, temperature, vibration, and power quality. By implementing sensors and connectivity solutions, data is constantly collected and analyzed to identify trends, detect faults early on, and predict maintenance needs. The process often involves the use of advanced software tools capable of handling large volumes of data and applying machine learning techniques to optimize predictive maintenance strategies. Online motor monitoring is integral to industries aiming for high-reliability performance, such as manufacturing, utilities, and energy production. Portable motor monitoring is typically used for periodic inspections, diagnostics, and condition-based maintenance tasks. Unlike online systems, portable motor monitoring involves the use of handheld or transportable devices that are temporarily connected to motors to conduct assessments. Technicians can employ various measurement instruments such as vibration analyzers, thermal cameras, and electrical signature analysis tools to evaluate the motor's health. Portable motor monitoring is valuable for plants and facilities that require regular maintenance checks without the infrastructure for a full-time online monitoring system or for diagnosing issues in remote or hard-to-reach places.

Deployment: Adoption of on-cloud monitoring to attain improved scalability

On-cloud motor monitoring systems utilize cloud computing resources to host and manage motor performance data. This deployment model offers scalability and flexibility, enabling businesses to adjust resources based on their requirements. On-cloud monitoring provides remote access to monitoring data from any location with internet connectivity, enhancing the convenience for maintenance teams and decision-makers. On-premise motor monitoring systems involve the deployment of hardware and software within the physical premises of the organization. This traditional approach to system deployment offers direct control over the monitoring infrastructure. This deployment grants full authority over the motor monitoring system, including data management, security protocols, and system upgrades.

End-Use: Need for effective monitoring to anticipate failures, manage peak loads and contribute to the dependable supply of electricity

In the aerospace & defense industry, motor monitoring is critical for the safety and functionality of aircraft and defense systems. These applications require highly precise and reliable motor monitoring to prevent failures that could lead to catastrophic outcomes. Motor monitoring in this sector helps maintain the peak performance of propulsion systems, onboard electronics, and actuation systems. The automotive industry utilizes motor monitoring to ensure the proper functioning of electric and hybrid vehicles. With the growth in electric vehicle (EV) technology, monitoring the condition of electric motors has become essential for vehicle performance, driving range, and battery life. In the chemicals sector, motor monitoring is employed to prevent motor failures that could cause operational disruptions or hazardous incidents. Monitoring systems track the health of motors driving pumps, mixers, and compressors, enabling proactive maintenance strategies in potentially corrosive or explosive environments. For the food & beverages industry, keeping motors running efficiently is necessary to prevent unexpected downtime and ensure food safety. Motor monitoring in this context often relates to refrigeration systems, conveyors, and processing equipment. Motors in the metals & mining industry often operate under severe conditions and heavy loads. Monitoring such motors is critical to detecting overheating, overloads, and other potential failures. By implementing motor monitoring systems, operators can enhance the safety and productivity of mining operations and reduce the costly downtime associated with motor failures. Motor monitoring in the oil & gas industry is essential for uninterrupted operations and safety. In power generation, reliable motor operation is paramount. Motor monitoring here targets the continuous operation of motors in power plants, including those used in cooling systems, fuel handling, and air pollution control systems. Effective monitoring can anticipate failures, manage peak loads, and contribute to the dependable supply of electricity.

Regional Insights:

The use of motor monitoring in the Americas is largely driven by mature industries such as manufacturing, energy, and utilities that demand high reliability and efficiency in their operations. North America, in particular, is home to several leading motor monitoring system manufacturers. These companies are known for their technological advancements and have a significant share in global markets. The Asia-Pacific region is experiencing rapid industrial growth, leading to increased adoption of motor monitoring systems, particularly in emerging economies such as China and India. The demand is also driven by a growing emphasis on energy efficiency and the need to comply with strict environmental regulations. Asia-Pacific is seeing a surge in the local production of motor monitoring systems, fueled by the booming industrial sector and local market demands. Countries such as Japan and South Korea are at the forefront of producing advanced motor monitoring technologies. In EMEA, motor monitoring is widely used across various sectors with a high focus on innovation and adherence to stringent European standards. Energy conservation directives and the Industry 4.0 movement are key drivers of motor monitoring adoption in this region. Europe is a strong hub for the production of motor monitoring systems, with German engineering often setting the standard for quality and innovation. The region's manufacturers are known for their focus on sustainable and smart technologies.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Motor Monitoring Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Motor Monitoring Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Motor Monitoring Market, highlighting leading vendors and their innovative profiles. These include AB SKF, ABB Ltd., Advantech Co., Ltd., ALS Limited, Analog Devices, Inc., Artesis, Baker Hughes Company, Balluff Inc., Banner Engineering India Pvt. Ltd., Dynapar Corporation, Eaton Corporation PLC, Emerson Electric Co., General Electric Company, Honeywell International Inc., IFM Electronic GmbH, Infoteam Group, KCF Technologies, KONČAR - Electrical Engineering Institute Ltd., Megger Baker Instruments, Mitsubishi Electric Corporation, National Instruments Corporation, Omron Corporation, PdMA Corporation, Phoenix Contact, Qualitrol Corp, Rockwell Automation, Inc., Schneider Electric SE, Siemens AG, SKF Group, and WEG Group.

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/motor-monitoring?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Motor Monitoring Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Technology, market is studied across Current Signature Analysis, Electric Discharge Current Measurement, Motor Current Monitoring, Oil Analysis, Speed & Sound Measurement, Thermal Monitoring, and Vibration Analysis. The Electric Discharge Current Measurement is projected to witness significant market share during forecast period.

Based on Monitoring Process, market is studied across Online Motor Monitoring and Portable Motor Monitoring. The Online Motor Monitoring is projected to witness significant market share during forecast period.

Based on Offering, market is studied across Hardware, Services, and Software. The Hardware is projected to witness significant market share during forecast period.

Based on Deployment, market is studied across On-Cloud and On-Premise. The On-Cloud is projected to witness significant market share during forecast period.

Based on End-Use, market is studied across Aerospace, Automotive, Energy & Power, Manufacturing, Mining, and Oil & Gas. The Mining is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Americas commanded largest market share of 42.21% in 2022, followed by Europe, Middle East & Africa.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Motor Monitoring Market, by Technology

7. Motor Monitoring Market, by Monitoring Process

8. Motor Monitoring Market, by Offering

9. Motor Monitoring Market, by Deployment

10. Motor Monitoring Market, by End-Use

11. Americas Motor Monitoring Market

12. Asia-Pacific Motor Monitoring Market

13. Europe, Middle East & Africa Motor Monitoring Market

14. Competitive Landscape

15. Competitive Portfolio

16. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Motor Monitoring Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Motor Monitoring Market?

3. What is the competitive strategic window for opportunities in the Motor Monitoring Market?

4. What are the technology trends and regulatory frameworks in the Motor Monitoring Market?

5. What is the market share of the leading vendors in the Motor Monitoring Market?

6. What modes and strategic moves are considered suitable for entering the Motor Monitoring Market?

Read More @ https://www.360iresearch.com/library/intelligence/motor-monitoring?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.