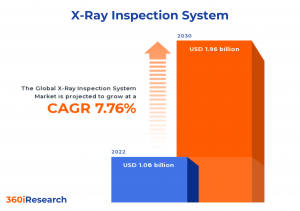

X-Ray Inspection System Market worth $1.96 billion by 2030 - Exclusive Report by 360iResearch

The Global X-Ray Inspection System Market to grow from USD 1.08 billion in 2022 to USD 1.96 billion by 2030, at a CAGR of 7.76%.

PUNE, MAHARASHTRA, INDIA , November 17, 2023 /EINPresswire.com/ -- The "X-Ray Inspection System Market by Component (Hardware, Software), Imaging Technique (Digital, Film), Dimension, Vertical - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global X-Ray Inspection System Market to grow from USD 1.08 billion in 2022 to USD 1.96 billion by 2030, at a CAGR of 7.76%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/x-ray-inspection-system?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

X-ray inspection systems are specialized equipment used across various industries for non-destructive testing and analysis. Leveraging the technologies of x-ray radiation, these systems are designed for scrutinizing the internal structure of multiple objects and materials without causing any damage or deformity. Growing awareness to analyze quality standards in the aerospace industry and rising safety concerns in industrial and security sectors are driving the market growth. Moreover, the increasing use of X-ray inspection systems in food and pharmaceutical industries for safety and security propels the market expansion. The high deployment cost of the X-ray inspection system, regulatory constraints regarding X-ray radiation safety & risk of radiation exposure to health hinder the X-ray Inspection Systems market growth. The rising use of 3D X-ray inspection systems in the automotive manufacturing industry, along with the adoption of technologically advanced X-ray systems, are expected to create significant growth opportunities in the market. In addition, Emerging trends such as the portability of X-ray systems and automation of inspection procedures have a substantial potential to expand the X-ray inspection systems market.

Dimension: Rising preference for 3D X-ray inspection system as it displays actual measurement and target point with 3D images

2D X-ray inspection systems are widely employed in various sectors, such as electronics, automobiles, construction, and more. They provide a quick and effective means for identifying internal product defects by radiating them with X-rays and producing a cross-sectional image. 3D X-ray inspection systems allow for the exploration of components in a three-dimensional space, enabling a more comprehensive and detailed inspection. It is preferable for complex products where thorough internal checking is required. Industries, including aerospace, energy, and high-end electronics, prefer 3D X-ray systems. The 2D system is preferable for quick and efficient product scanning. However, for complex products requiring detailed internal viewing, a 3D system is undoubtedly better.

Component: Expanding hardware manufacturing with advanced tools for resolution, precision, and industry-specific efficiency

The hardware for X-ray inspection systems comprises tangible components such as the X-ray tube, sensor arrays, and image processing units. These systems could range from basic set-ups to high-end, sophisticated machinery, each serving different exigencies across various industries, including automotive, food and beverage, electronic manufacturing, and more. The software component of the X-Ray inspection system is the control center that manages and manipulates the data or images captured by the hardware. It includes the operating system, user interface, image analysis software, database management, and, often, cloud-based storage options. The software component significantly affects the system's ease of use, efficiency, and, ultimately, the quality of the analysis. In comparison, hardware manufacturers have made numerous innovative strides toward providing tools that deliver resolution, precision, and efficiency under diverse industry requirements. Software providers have each contributed substantially to the efficiency and reliability of X-ray inspection data analysis.

Imaging Technique: Growing utilization of digital X-ray inspection systems as it allows for greater resolution of detail

Digital X-ray inspection systems are becoming preferred for entry-level and advanced applications due to their superior imaging quality, instantaneous display, and seamless data manipulation. Computed radiography is widely used in medical, industrial, and scientific fields. This is primarily due to its relatively low cost compared to other digital solutions, ability to use existing imaging equipment, and high-quality image resolution. Computed tomography provides a more complete view of the interior of objects by producing 2D images of a 'slice' and cross-section through the object. This ability to observe internal structures in high-resolution 3D is driving demand for CT-based systems. Direct radiography system has the ability to provide near-instant access to radiographic images, higher throughput, and superior image quality. Film-based X-ray inspection systems continue to excel in specific scenarios based on their unique advantages, including cost-effectiveness, simplicity of use, and the tactile aspect of physical films. Digital imaging provides high resolution, instant viewing, and easy data transfer, and it comes at a significantly higher cost than film-based systems. The film-based systems are affordable and simple to operate, they lack immediate image viewability, and the handling and storage of physical films can be challenging.

Vertical: Significant role of X-ray inspection system in food & pharmaceutical sector as it identify a variety of physical contaminants

The aerospace industry's demand for X-ray inspection systems has grown due to their non-destructive nature, accuracy, and the critical need for safety in aircraft components. These systems scan parts for defects, ensuring the highest quality control standards. Automotive sectors rely on X-ray inspection to assess engine parts, electronic components, tires, and airbags. X-ray inspection systems are indispensable for the electronics & semiconductors sector to detect defects like soldering faults or missing components without damaging the product. With the increasing product safety standards in the food & pharmaceuticals sector, X-ray inspection systems serve to detect contaminants, analyze products for size and shape, and verify packaged product weights. Manufacturing firms adopt X-ray inspection systems for flawless quality control. In the oil & gas industry, X-ray inspection systems are essential for assessing pipeline integrity, corrosion, and weld quality. The power generation sector uses X-ray inspection systems for turbine blade inspection, weld quality, and structural integrity of nuclear reactor components.

Regional Insights:

The developed countries in North America, particularly the United States and Canada show a high demand for X-ray inspection systems due to their technologically advanced industries and stringent safety standards. Investments in this region are primarily driven by advancements in digital technologies, improving inspection systems' efficiency and accuracy. Furthermore, growing awareness of quality assurance and enhanced productivity has increased demand. The European Union exhibits strong demand for X-ray inspection Systems, with Germany leading the market due to its robust manufacturing sector. The introduced quality assurance policies by the European Union have further bolstered the need for sophisticated inspection systems in the manufacturing industry. The X-ray inspection system market in the Middle East and Africa is growing steadily as these regions are experiencing increased industrialization. Investments in these regions are primarily directed towards oil and gas, construction, and power generation sectors, which have considerable demand for advanced inspection systems. Asia-Pacific, with its booming economies, massive population, and continuous industrialization, is expected to exhibit the fastest growth in demand for X-ray inspection systems. Especially in countries such as China and India, industrial X-ray applications, healthcare advancements, and increasing safety regulations are several significant driving factors for this surge in demand.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the X-Ray Inspection System Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the X-Ray Inspection System Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the X-Ray Inspection System Market, highlighting leading vendors and their innovative profiles. These include 3DX-RAY Ltd., A&D Co. Ltd., ANRITSU CORPORATION, CASSEL Messtechnik GmbH BY TASI Group, Comet Group, Heat and Control, Inc., Ishida Co., Ltd., Körber Pharma GmbH, LOMA SYSTEMS, Maha X-ray Equipment Private Limited, MATSUSADA PRECISION, Inc., Metrix NDT Limited, Mettler-Toledo International Inc., Minebea Intec, Nikon Metrology, Inc., Nordson Corporation, Sapphire Inspection Systems Ltd, Sesotec GmbH, Shimadzu Corporation, SYSTEM SQUARE INC., TDI Packsys, LLC, Techik Instrument Co., Ltd., The Multivac Group, Viscom AG, VisiConsult X-ray Systems & Solutions GmbH, and VJ Group, Inc..

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/x-ray-inspection-system?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the X-Ray Inspection System Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Component, market is studied across Hardware and Software. The Software is projected to witness significant market share during forecast period.

Based on Imaging Technique, market is studied across Digital and Film. The Digital is further studied across Computed Radiography (CR), Computed Tomography (CT), and Direct Radiography (DR). The Film is projected to witness significant market share during forecast period.

Based on Dimension, market is studied across 2D X-Ray and 3D X-Ray. The 2D X-Ray is projected to witness significant market share during forecast period.

Based on Vertical, market is studied across Aerospace, Automotive, Electronics & Semiconductors, Food & Pharmaceuticals, Manufacturing, Oil & Gas, and Power Generation. The Aerospace is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Americas commanded largest market share of 37.96% in 2022, followed by Europe, Middle East & Africa.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. X-Ray Inspection System Market, by Component

7. X-Ray Inspection System Market, by Imaging Technique

8. X-Ray Inspection System Market, by Dimension

9. X-Ray Inspection System Market, by Vertical

10. Americas X-Ray Inspection System Market

11. Asia-Pacific X-Ray Inspection System Market

12. Europe, Middle East & Africa X-Ray Inspection System Market

13. Competitive Landscape

14. Competitive Portfolio

15. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the X-Ray Inspection System Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the X-Ray Inspection System Market?

3. What is the competitive strategic window for opportunities in the X-Ray Inspection System Market?

4. What are the technology trends and regulatory frameworks in the X-Ray Inspection System Market?

5. What is the market share of the leading vendors in the X-Ray Inspection System Market?

6. What modes and strategic moves are considered suitable for entering the X-Ray Inspection System Market?

Read More @ https://www.360iresearch.com/library/intelligence/x-ray-inspection-system?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+ 1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.