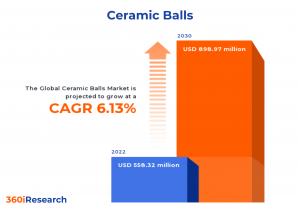

Ceramic Balls Market worth $898.97 million by 2030, growing at a CAGR of 6.13% - Exclusive Report by 360iResearch

The Global Ceramic Balls Market to grow from USD 558.32 million in 2022 to USD 898.97 million by 2030, at a CAGR of 6.13%.

PUNE, MAHARASHTRA, INDIA, November 15, 2023 /EINPresswire.com/ -- The "Ceramic Balls Market by Type (Active Ceramic Balls, Inert Ceramic Balls), Material (Alumina Based, Silicon Based, Zirconia Based), Application, End-Use - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Ceramic Balls Market to grow from USD 558.32 million in 2022 to USD 898.97 million by 2030, at a CAGR of 6.13%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/ceramic-balls?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Ceramic balls are a type of advanced precision component utilized in various industrial applications due to their unique properties and characteristics. Composed of ceramic materials such as aluminum oxide (Al2O3), silicon nitride (Si3N4), zirconium oxide (ZrO2), or silicon carbide (SiC), these spherical-shaped elements exhibit exceptional hardness, wear resistance, corrosion resistance, and dimensional stability compared to traditional ball bearing materials such as steel. In addition to their remarkable durability, ceramic balls possess low density, high elastic modulus, and low coefficients of thermal expansion, contributing to their minimal frictional losses and high-speed capabilities under varying temperature conditions. They are widely used as rolling elements in bearings to reduce friction and improve performance across various industries, including aerospace, automotive, petrochemicals, medical equipment manufacturing, and electronics processing plants. The global ceramic balls market is experiencing robust growth due to expanding demand from end-use industries focused on sustainability initiatives alongside the rising utility of ceramic balls in the chemical industry. As a result of stringent environmental regulations targeting emission reduction goals coupled with the growing adoption of electric vehicles globally, the need for lightweight components offering improved performance has surged significantly. On the other hand, high production costs resulting from intricate manufacturing processes and Strict regulations on the manufacturing process due to health and environmental concerns impede market expansion. However, collaborative research activities for the development of ceramic balls and the emerging application of ceramic balls in wind farms create an opportunity for the ceramic balls market to grow in the coming years.

End-Use: Growing utilization of ceramic balls across automotive sector for hybrid engines and transmissions

The global ceramic balls market is expanding rapidly, driven by the growing demand for high-performance materials across various end-use industries. In the aerospace industry, ceramic balls are extensively used in ball bearings and valve components as they reduce friction and wear in high-speed applications while ensuring enhanced durability and fuel efficiency. The automotive industry relies on ceramic balls for reducing friction in engine components such as fuel injectors and water pumps. They play a crucial role in electric vehicle motor bearings due to their electrical insulation properties that prevent current leakage. Ceramic balls are utilized within chemical processing plants as catalyst carriers or support media due to their inertness towards corrosive environments. They facilitate optimal performance by evenly distributing heat and mass while maintaining structural integrity under extreme conditions. The medical sector utilizes ceramic balls in orthopedic implants and dental prosthetics owing to their biocompatibility, wear resistance, and long-lasting performance. In oil & gas operations, ceramic balls are essential for withstanding high-pressure environments found in downhole equipment, pumps, and valves. Their excellent wear and corrosion resistance make them ideal for harsh operating conditions prevalent in this sector.

Material: Growing preference for silicon-based ceramic balls in semiconductor manufacturing equipment

The global ceramic balls market is segmented based on material into three primary categories: alumina-based, silicon-based, and zirconia-based. Alumina-based ceramic balls are widely used due to their excellent wear resistance, high mechanical strength, and good electrical insulation properties. These balls are commonly used in automotive, aerospace, chemical processing, and bearings manufacturing industries. Silicon-based ceramic balls offer superior wear resistance coupled with low thermal expansion properties compared to other materials. They are mainly utilized in industries requiring extreme temperatures or harsh environments, such as semiconductor manufacturing equipment and solar energy systems. Zirconia-based ceramic balls have high fracture toughness, excellent wear resistance, and low thermal conductivity properties. These features make them suitable for applications requiring high-impact resistance, such as grinding media, milling operations, and valve components. Alumina-based ceramic balls are preferred in industries requiring high mechanical strength and suitable electrical insulation properties, silicon-based ceramic balls are ideal for extreme temperature conditions and harsh environments, and zirconia-based ceramic balls excel in applications needing high impact resistance.

Application: Expanding the application of ceramic balls as grinding media in various milling processes

Ceramic balls are widely used in the bearing industry due to their exceptional properties, such as low density, high hardness, low friction coefficient, and corrosion resistance, making them an ideal option for applications that demand high performance and reliability, especially in industries, including aerospace, automotive, and medical equipment. Ceramic balls are also utilized as grinding media in various milling processes for their superior wear resistance and chemical inertness, as they offer significant advantages over traditional steel grinding media, such as they withstand higher temperatures without deformation or loss of hardness. Industries such as mining, cement, power generation, and chemical processing prefer ceramic grinding balls for improved process efficiency and extended equipment lifetimes. Ceramic balls have found application in valve components due to their exceptional wear resistance, corrosion resistance, and high-temperature tolerance. They are increasingly employed in critical fluid control systems across industries, including oil & gas refining, chemical processing plants, and power generation facilities where conventional materials fail under harsh operating conditions. The usage of ceramic balls in valve components, such as ball valves and check valves, offers advantages such as longer service life, reduced maintenance costs, and improved flow control.

Type: Increasing adoption of active ceramic balls for reducing energy consumption

Active ceramic balls are a type of ceramic ball that have catalytic properties and are widely used in the petrochemical industry, environmental protection, and other industries where chemical reactions are needed, acting as catalyst carriers or support media in various reactors, such as fluidized bed reactors and fixed-bed reactors. They offer high thermal stability and excellent mechanical strength and withstand high temperatures and pressure without losing their performance. They enhance chemical reaction rates, improve product yield, reduce energy consumption, and lower pollution levels. Inert ceramic balls serve as support media in various industrial processes such as petrochemicals, fertilizers, natural gas production, and air separation plants. They are chemically inert and do not participate in any chemical reactions within the systems they support, which makes them ideal for use in applications where chemical stability is crucial to maintaining process efficiency. They are effective in maintaining uniform temperature distribution within a reactor bed while preventing mass transfer limitations caused by channeling or hot spots. Additionally, due to their excellent mechanical strength, these balls withstand high temperatures, pressures, and corrosive environments. Active ceramic balls generally have higher costs associated with manufacturing due to their specialized catalytic properties compared to inert ceramic balls.

Regional Insights:

North America holds a considerable position in the ceramic balls industry in the Americas region due to its well-established automotive and aerospace sectors. In the United States, increased investments in oil refineries and chemical plants have boosted the demand for high-performance materials such as ceramic balls. The European Union contributes significantly to the EMEA ceramic ball landscape with robust manufacturing capabilities across various sectors. Automotive manufacturers collaborate with researchers to develop lightweight components using ceramic materials to enhance fuel efficiency while reducing environmental impact across Europe. Middle Eastern countries invest heavily in non-oil sectors, such as petrochemicals that require corrosion-resistant materials, including ceramic balls, due to harsh operating environments. In Africa, growing economies focusing on industrialization create opportunities for advanced material solutions providers catering to mining and cement manufacturing sectors. Asia-Pacific is a developed and growing market for ceramic balls, primarily fueled by robust expansion in the automotive and electronics industries. China, Japan, South Korea, and India are the leading contributors to APAC's growth due to their rapid industrialization and increased focus on energy efficiency. The adoption of ceramic balls in electric vehicles (EVs) is another key driver in this region since these materials significantly reduce friction and energy loss, optimizing battery performance.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Ceramic Balls Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Ceramic Balls Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Ceramic Balls Market, highlighting leading vendors and their innovative profiles. These include AB SKF, Accumet Materials Co., Akron Porcelain & Plastics Co., AKS Bearings Limited, ANTS Ceramics Pvt Ltd, Astro Met, Inc., Axens by IFP group, BASF SE, Carter Manufacturing Limited, Compagnie de Saint-Gobain S.A., CoorsTek, Inc. by Momentive Technologies, Devson Catalyst Private Limited, Fineway Inc., FT/F Co.,Ltd., Guangzhou Chemxin Environmental Material Co., Ltd. by Jiangxi Xintao Technology Co., Ltd, Hi-Tech Seals Inc. by Carco Group, Honeywell International Inc., Industrie Bitossi S.p.A., Madhya Bharat Ceramics, Metalball S.A.S., Ortech, Incorporated, Saint-Gobain Ceramics & Plastics, Inc., Shandong Qishuai Wear Resistant Equipment Co., Ltd., SKF Group, Sorbead India, Tipton Corp., TN United Kingdom, Ltd, Topack Ceramics Pvt. Ltd. by Vedanta Limited, Toshiba Materials Co., Ltd., Tsubaki Nakashima Co., Ltd. by The Carlyle Group, and Xiamen Innovacera Advanced Materials Co., Ltd..

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/ceramic-balls?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Ceramic Balls Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Type, market is studied across Active Ceramic Balls and Inert Ceramic Balls. The Inert Ceramic Balls is projected to witness significant market share during forecast period.

Based on Material, market is studied across Alumina Based, Silicon Based, and Zirconia Based. The Alumina Based is projected to witness significant market share during forecast period.

Based on Application, market is studied across Bearing, Grinding, and Valve. The Valve is projected to witness significant market share during forecast period.

Based on End-Use, market is studied across Aerospace, Automotive, Chemical, Medical, and Oil & Gas. The Oil & Gas is projected to witness significant market share during forecast period.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Asia-Pacific commanded largest market share of 38.81% in 2022, followed by Europe, Middle East & Africa.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Ceramic Balls Market, by Type

7. Ceramic Balls Market, by Material

8. Ceramic Balls Market, by Application

9. Ceramic Balls Market, by End-Use

10. Americas Ceramic Balls Market

11. Asia-Pacific Ceramic Balls Market

12. Europe, Middle East & Africa Ceramic Balls Market

13. Competitive Landscape

14. Competitive Portfolio

15. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Ceramic Balls Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Ceramic Balls Market?

3. What is the competitive strategic window for opportunities in the Ceramic Balls Market?

4. What are the technology trends and regulatory frameworks in the Ceramic Balls Market?

5. What is the market share of the leading vendors in the Ceramic Balls Market?

6. What modes and strategic moves are considered suitable for entering the Ceramic Balls Market?

Read More @ https://www.360iresearch.com/library/intelligence/ceramic-balls?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+ 1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.