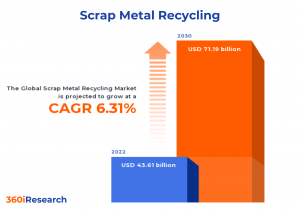

Scrap Metal Recycling Market worth $71.19 billion by 2030, growing at a CAGR of 6.31% - Exclusive Report by 360iResearch

The Global Scrap Metal Recycling Market to grow from USD 43.61 billion in 2022 to USD 71.19 billion by 2030, at a CAGR of 6.31%.

PUNE, MAHARASHTRA, INDIA, November 10, 2023 /EINPresswire.com/ -- The "Scrap Metal Recycling Market by Scrap Type (New Scrap, Old Scrap), Metal Type (Ferrous, Non-Ferrous), Equipment, Source - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Scrap Metal Recycling Market to grow from USD 43.61 billion in 2022 to USD 71.19 billion by 2030, at a CAGR of 6.31%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/scrap-metal-recycling?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

The scrap metal recycling promotes sustainability by transforming waste metal materials into valuable resources for various industrial applications. Key players in the market involve scrap collectors, brokers, processors, smelters, refiners, manufacturers, and end-users. Industries such as automotive, construction, electronics, aerospace, shipbuilding, consumer goods manufacturing, and packaging utilize recycled metals to create new products such as steel rebar or structural beams for infrastructure projects. Massive growth in electronic waste generation and disposal and increasing use of recycled metal products by automotive and aerospace applications drive the demand for scrap metal recycling. Growing awareness of environmental conservation and resource efficiency has increased the demand for recycled metals. Government regulations on waste management encourage industries to adopt sustainable approaches and contribute to the circular economy. High costs associated with scrap metal recycling equipment and separation procedures and inappropriate infrastructure availability for scrap collection and separation in emerging economies may restrict the growth potential of the market. Increasing investments in recycling for facility expansion worldwide and ongoing technological advancements in scrap metal recycling equipment and procedures boost potential opportunities within the market.

Source: High availability of scrap metal from the automotive and building & construction industry

The aerospace industry prioritizes high-quality recycled metals such as titanium, aluminum, and nickel-based alloys for their strength-to-weight ratio and resistance to extreme temperatures. Cost reduction and sustainability drive the demand for steel and aluminum scrap in the automotive sector. Building and construction activities heavily consume recycled copper, iron, stainless steel, and aluminum in various applications. E-waste recycling is essential within the electronics appliances sector due to rapid technological advancements. Equipment manufacturing relies on durable recycled metals such as steel and cast iron for heavy machinery components production. Shipbuilding primarily uses recycled steel for economic and environmental benefits without compromising quality or durability. The scrap metal recycling industry is crucial for meeting the unique requirements of diverse sectors while promoting sustainability and cost-effectiveness.

Equipment: Growing adoption of briquetting machines in industries that generate a large volume of metal waste

Briquetting machines consolidate metal shavings into compact briquettes for convenient handling and transportation. Granulating machines crush scrap metal into small granules for separation or melting processes. Metal analyzers accurately identify the composition of various metal alloys in scrap materials to ensure proper recycling procedures. Shears cut large scrap metal pieces into manageable sizes for processing. Shredders reduce mixed scrap metal volumes into smaller fragments for easier sorting and recycling. The scrap metal recycling industry relies on specialized equipment for efficient and precise processing. Selecting suitable machinery depends on the specific needs and preferences of manufacturers while focusing on recent developments as they continue to innovate and enhance their offerings.

Metal Type: Significant use of ferrous metals for heavy-duty applications

Ferrous metals, including carbon steel, stainless steel, cast iron, and wrought iron, contain iron and are magnetic in nature. Industries such as construction, automotive, and heavy machinery utilize these metals for their strength and durability. Carbon steel is an alloy mainly composed of iron and carbon. Carbon steel accounts for around 90% of global steel production, and its recyclability makes it highly valued in the scrap metal recycling industry. Cast iron is a set of iron-carbon alloys with carbon content generally higher than 2%. It exhibits excellent castability and relatively high wear resistance and is widely used in automotive components, pipes, machinery parts, and cookware. Engineering steels are specialized ferrous alloys with specific properties designed for demanding applications such as aerospace components, automotive parts, heavy machinery gears, bearings, springs, and more. Stainless steel is an alloy comprising at least 10.5% chromium by weight, which offers superior corrosion resistance compared to other types of steel due to the accumulation of a protective chromium oxide layer. Non-ferrous metals, including aluminum, copper, lead, zinc, nickel, titanium, gold, silver, brass, and bronze, lack significant iron content and exhibit non-magnetic properties. They are more corrosion-resistant than ferrous metals and find applications in electronics components, piping systems, the aerospace industry, automotive components, and the renewable energy sector. Aluminum is a lightweight, non-ferrous metal with excellent corrosion resistance and conductivity properties. Aluminum is one of the most recycled metals globally and is widely used in the transportation, packaging, construction, and electrical industries. Brass is an alloy primarily formed of copper and zinc, exhibiting good corrosion resistance and high thermal and electrical conductivity. Copper is a reddish, non-ferrous metal known for its high electrical conductivity, malleability, and ductility. This makes it highly sought after in electrical wiring systems, plumbing fixtures, roofing materials, and electronic components. Nickel is a silver-white metal with high tensile strength and excellent corrosion resistance properties under various conditions. In recycling processes, ferrous metals benefit from well-established infrastructures employing shredding, sorting, and melting, while non-ferrous recycling involves complex pyrometallurgical or hydrometallurgical treatments, resulting in higher costs. Ferrous and non-ferrous metal recycling plays a crucial role in reducing greenhouse gas emissions, conserving natural resources, and promoting sustainable growth across various industries.

Scrap Type: Old scrap offers significant opportunities for resource conservation and landfill diversion

New scrap, referred to as prompt or industrial scrap, is produced during manufacturing processes and the fabrication of new metal products. Its high-quality properties make it desirable for manufacturers due to its consistency in quality, high-metal content, and ease of processing without extensive purification. Old scrap remains an essential raw material source that helps conserve resources while diverting waste from landfills. Choosing between new scrap and old scrap depends on factors such as cost-effectiveness, availability, environmental considerations, and specific industry needs. Companies must closely monitor market trends and regulatory developments to optimize their involvement with either or both types of scrap materials accordingly.

Regional Insights:

Industrialization has increased the adoption of scrap metal recycling services in the United States and Canada. The North American automotive and construction industries generate significant amounts of ferrous and non-ferrous metals as waste products that require recycling. The European Union's circular economy initiative aims at reducing waste generation by encouraging resource efficiency through recycling efforts. Stringent regulations regarding waste management and material recovery efforts bind EU countries. Germany and Turkey are major importers of ferrous scrap materials within Europe, with a combined import volume exceeding 30 million metric tons in 2022. The Middle East is experiencing increased adoption rates for scrap metal recycling services due to rapid urbanization and infrastructure development projects. Asia-Pacific countries such as China, Japan, and India are major steel producers. Rapid urbanization and industrial development have expanded the steel demand, leading to significant investment in efficient recycling processes.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Scrap Metal Recycling Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Scrap Metal Recycling Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Scrap Metal Recycling Market, highlighting leading vendors and their innovative profiles. These include Al Habari Engineering, Alcoa Corporation, Andritz AG, ArcelorMittal S.A., Arfin India Limited, Audubon Metals LLC by Koch Industries, Inc., Aurubis AG, Baosteel Co., Ltd., CASS, Inc., Commercial Metals Company, Constellium SE, Crestwood Metal Corp., European Metal Recycling Limited, Ferrous Processing & Trading, Great Lakes Electronics Corporation, Hindalco Industries Limited, Hulamin Limited, Kuusakoski Oy, Matalco Inc., Metalico, Inc. by Ye Chiu Metal Recycling (China) Ltd., Norsk Hydro ASA, Nucor Corporation, Nupur Recyclers Limited, OmniSource, LLC, Palco Recycle Industries Limited, Prime Materials Recovery Inc., Radius Recycling, Real Alloy Recycling, LLC, Remondis SE & Co. KG, Rio Tinto PLC, Scepter, Inc., Sims Limited, Tom Martin & Company Ltd., Tri-Arrows Aluminum, Inc., and TRIMET SE.

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/scrap-metal-recycling?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Scrap Metal Recycling Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Scrap Type, market is studied across New Scrap and Old Scrap. The New Scrap commanded largest market share of 67.43% in 2022, followed by Old Scrap.

Based on Metal Type, market is studied across Ferrous and Non-Ferrous. The Ferrous is further studied across Carbon Steel, Cast Iron, Engineering Steel, and Stainless Steel. The Non-Ferrous is further studied across Aluminum, Brass, Copper, and Nickel. The Non-Ferrous commanded largest market share of 72.67% in 2022, followed by Ferrous.

Based on Equipment, market is studied across Briquetting Machines, Granulating Machines, Metal Analysers, Shears, and Shredders. The Briquetting Machines commanded largest market share of 27.70% in 2022, followed by Granulating Machines.

Based on Source, market is studied across Aerospace, Automotive, Building & Construction, Electronics Appliances, Equipment Manufacturing, and Shipbuilding. The Automotive commanded largest market share of 21.12% in 2022, followed by Building & Construction.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Georgia, Illinois, Massachusetts, New Jersey, New York, North Carolina, Ohio, Pennsylvania, Texas, and Washington. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Asia-Pacific commanded largest market share of 40.12% in 2022, followed by Europe, Middle East & Africa.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Scrap Metal Recycling Market, by Scrap Type

7. Scrap Metal Recycling Market, by Metal Type

8. Scrap Metal Recycling Market, by Equipment

9. Scrap Metal Recycling Market, by Source

10. Americas Scrap Metal Recycling Market

11. Asia-Pacific Scrap Metal Recycling Market

12. Europe, Middle East & Africa Scrap Metal Recycling Market

13. Competitive Landscape

14. Competitive Portfolio

15. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Scrap Metal Recycling Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Scrap Metal Recycling Market?

3. What is the competitive strategic window for opportunities in the Scrap Metal Recycling Market?

4. What are the technology trends and regulatory frameworks in the Scrap Metal Recycling Market?

5. What is the market share of the leading vendors in the Scrap Metal Recycling Market?

6. What modes and strategic moves are considered suitable for entering the Scrap Metal Recycling Market?

Read More @ https://www.360iresearch.com/library/intelligence/scrap-metal-recycling?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.