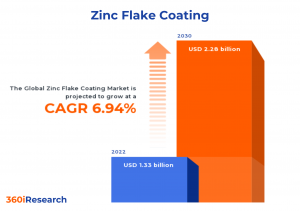

Zinc Flake Coating Market worth $2.28 billion by 2030, growing at a CAGR of 6.94% - Exclusive Report by 360iResearch

The Global Zinc Flake Coating Market to grow from USD 1.33 billion in 2022 to USD 2.28 billion by 2030, at a CAGR of 6.94%.

PUNE, MAHARASHTRA, INDIA, November 10, 2023 /EINPresswire.com/ -- The "Zinc Flake Coating Market by Type (Solvent-Based, Water-Based), Coating Type (Inorganic Coats, Organic Coats), Coating Technique, End-Use Industry - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Zinc Flake Coating Market to grow from USD 1.33 billion in 2022 to USD 2.28 billion by 2030, at a CAGR of 6.94%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/zinc-flake-coating?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Zinc flake coating is a corrosion-resistant coating that effectively protects various metal surfaces. Zinc flake coating is primarily used to prevent rust and corrosion on steel and other ferrous substrates. Rapid industrialization and infrastructure development activities increase the demand for corrosion-resistant coatings, including zinc flake coatings. The continuous expansion of the automotive industry is elevating the usage of zinc flake coatings on various automotive components, including fasteners, springs, chassis, and body parts, to provide corrosion protection and improve durability. However, developing alternative coating technologies and materials, such as nano-coatings and advanced polymers, challenges the growth of the zinc flake coating market. Developing self-healing and smart coatings that can repair minor damage and provide additional functionalities that enhance the value proposition of zinc flake coatings is expected to create opportunities for market growth.

Coating Technique: Widespread adoption of automated spraying technique attributed to precise control

Spraying is a widely used coating technique for zinc flake coatings, which involves using spray guns and automated spraying systems to apply the coating onto the surface evenly. This technique allows for precise control over the coating thickness and coverage. Spraying is used for large or complex surfaces, such as automotive body parts, requiring an even and uniform coating. Dip-spinning is a technique in which parts are immersed in a tank or container filled with the zinc flake coating solution, requiring coating. The parts are then spun at high speeds, causing the excess coating solution to be flung off by centrifugal force. Rack-mounted dip-spinning is a variation of the dip-spinning technique where the parts are mounted on racks or fixtures before immersion in the coating solution. This technique is commonly used for larger or irregularly shaped parts that cannot be immersed individually. The dip-drain coating is a technique where the parts are dipped into the coating solution and lifted to allow excess coating to drain off.

End-Use Industry: Higher consumption of zinc flake coatings in rapidly growing automotive and electronics industries

The automotive industry extensively uses zinc flake coatings for corrosion protection of automotive components, such as fasteners, springs, brake systems, chassis, and body parts. In the construction industry, zinc flake coatings protect structural elements, steel reinforcements, and fasteners in buildings, bridges, and infrastructure projects. These coatings provide a barrier against corrosion, extending the lifespan of the construction materials. Zinc flake coatings are applied to components of industrial machinery exposed to harsh environments, such as pumps, valves, turbines, and machine parts. Zinc flake coatings are used to protect pipelines, offshore structures, storage tanks, valves, and other equipment from corrosion. These coatings provide effective corrosion resistance, even in aggressive environments, reducing maintenance costs and enhancing safety. Additionally, zinc flake coatings are used in the electrical & electronics industry to protect metal components from corrosion. They are applied to electrical connectors, enclosures, terminals, and other metal parts.

Coating Type: Significant benefits of organic zinc flake coats in maintaining corrosion protection.

Organic zinc flake coats are formulated using organic binders, resins, zinc flakes, and other additives. These coatings provide excellent corrosion protection and offer additional benefits such as flexibility, impact resistance, and color options. Inorganic zinc flake coats are formulated using inorganic binders based on silicate or phosphate chemistry, zinc flakes, and other additives. Inorganic zinc flake coats are used in industries such as oil & gas, marine, and heavy machinery, where superior corrosion resistance is critical.

Type: Growing demand for solvent-based zinc flake coatings owing to their faster drying times

Solvent-based zinc flake coatings offer superior protection against corrosion, salts, and UV rays, making them an ideal choice for applications exposed to harsh environmental conditions. Solvent-based zinc flake coatings are formulated using organic solvents that contain a blend of zinc flakes, binders, pigments, and other additives. The solvent easily evaporates during the curing process, leaving a protective layer of zinc on the surface. Water-based zinc flake coatings, also known as aqueous or waterborne zinc flake coatings, utilize water as the primary solvent for the coating formulation. These coatings consist of zinc flakes, binders, pigments, and additives dispersed in water.

Regional Insights:

Significant infrastructure development activities, such as the construction of roads, bridges, and airports across Asia-Pacific and South America, drive the demand for zinc flake coatings. The growing focus on renewable energy sources across India, Japan, China, and Australia is expected to expand the application of zinc flake coatings to protect components used in renewable energy infrastructure, such as wind turbine towers, solar panel frames, and support structures. The presence of well-established automotive manufacturers focused on increasing the production of vehicles across the U.S., Canada, the UK, and Germany is expanding the adoption of zinc flake coatings for corrosion protection of various automotive components, including fasteners, springs, chassis, and body parts. The increasing maintenance and repair activities in industries, including oil & gas and chemical processing in EMEA, are raising the demand for zinc flake coatings for recoating and repairing existing surfaces and providing corrosion protection in these industries.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Zinc Flake Coating Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Zinc Flake Coating Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Zinc Flake Coating Market, highlighting leading vendors and their innovative profiles. These include Aalberts N.V., ALTANA AG, ALU - FIN, American Elements, Anochrome Group, Atotech Deutschland GmbH & Co. KG by MKS Instruments, Inc., Aum Dacro Coatings, AVL METAL POWDERS n.v., EJOT Holding GmbH & Co. KG, Ewald Dörken AG, Fabory Nederland B.V., Forplan AG, Holder GmbH, Hunan Jinhao New Material Technology Co., Ltd, Huster Oberflächentechnik GmbH, Kansai Helios Coatings GmbH by Kansai Paint Co.,Ltd., Keys & Clamps, Klimas sp. z o. o., Licco Group, Noelson Chemicals, NOF CORPORATION, Novamet Specialty Products Corporation, Otto Chemie Pvt. Ltd., PPG Industries, Inc., Progressive Surface Systems, RIE Coatings, ROTOVER Lackiertechnik GmbH, Shiva co., Shree Balaji Industries LLP, Sika AG, Thai Parkerizing Co., Ltd., The DECC Company, The Magni Group, Inc., Varun Advance Coatings, Wellcoat Tech, Yuken Industrial Co., Ltd., and Zincotec Co.,Ltd.

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/zinc-flake-coating?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Zinc Flake Coating Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Type, market is studied across Solvent-Based and Water-Based. The Solvent-Based commanded largest market share of 67.88% in 2022, followed by Water-Based.

Based on Coating Type, market is studied across Inorganic Coats and Organic Coats. The Inorganic Coats commanded largest market share of 74.88% in 2022, followed by Organic Coats.

Based on Coating Technique, market is studied across Dip-drain Coating, Dip-spinning, Rack-mounted Dip-spinning, and Spraying. The Dip-drain Coating commanded largest market share of 40.54% in 2022, followed by Rack-mounted Dip-spinning.

Based on End-Use Industry, market is studied across Automotive, Construction, Electrical & Electronics, Industrial Machinery, and Oil & Gas. The Automotive commanded largest market share of 38.12% in 2022, followed by Construction.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across California, Florida, Illinois, New York, Ohio, Pennsylvania, and Texas. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Europe, Middle East & Africa commanded largest market share of 40.87% in 2022, followed by Asia-Pacific.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Zinc Flake Coating Market, by Type

7. Zinc Flake Coating Market, by Coating Type

8. Zinc Flake Coating Market, by Coating Technique

9. Zinc Flake Coating Market, by End-Use Industry

10. Americas Zinc Flake Coating Market

11. Asia-Pacific Zinc Flake Coating Market

12. Europe, Middle East & Africa Zinc Flake Coating Market

13. Competitive Landscape

14. Competitive Portfolio

15. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Zinc Flake Coating Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Zinc Flake Coating Market?

3. What is the competitive strategic window for opportunities in the Zinc Flake Coating Market?

4. What are the technology trends and regulatory frameworks in the Zinc Flake Coating Market?

5. What is the market share of the leading vendors in the Zinc Flake Coating Market?

6. What modes and strategic moves are considered suitable for entering the Zinc Flake Coating Market?

Read More @ https://www.360iresearch.com/library/intelligence/zinc-flake-coating?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+ +1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.