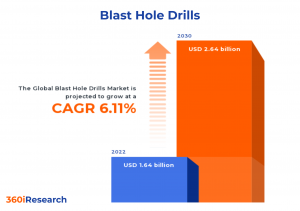

Blast Hole Drills Market worth $2.64 billion by 2030, growing at a CAGR of 6.11% - Exclusive Report by 360iResearch

The Global Blast Hole Drills Market to grow from USD 1.64 billion in 2022 to USD 2.64 billion by 2030, at a CAGR of 6.11%.

PUNE, MAHARASHTRA, INDIA, November 8, 2023 /EINPresswire.com/ -- The "Blast Hole Drills Market by Type (Large-range Drilling Rig, Mid-range Drilling Rig), Mode of Operation (Automatic, Manual), Power Transmission, Drilling Methods, Application - Global Forecast 2023-2030" report has been added to 360iResearch.com's offering.The Global Blast Hole Drills Market to grow from USD 1.64 billion in 2022 to USD 2.64 billion by 2030, at a CAGR of 6.11%.

Request a Free Sample Report @ https://www.360iresearch.com/library/intelligence/blast-hole-drills?utm_source=einpresswire&utm_medium=referral&utm_campaign=sample

Blast hole drills play a critical role in the mining and construction industries, as they are specifically designed for drilling precise and efficient holes into the earth's surface. These holes are subsequently filled with explosives to break and fragment the targeted rock or ground material, enabling the extraction of valuable minerals or preparing a site for construction projects. Key factors influencing blast hole drill performance include the drill's penetration rate, accuracy, and overall productivity. In recent years, the number of mineral and metal exploration projects increased across countries, creating demand for blast hole drills. However, technical limitations associated with blast hole drills can impact their adoption. Technological advancements have improved the operational efficiency of navigation systems and automation capabilities that optimize drilling patterns and reduce human error while ensuring worker safety. With an increasing demand for minerals and infrastructure development projects across the globe, blast hole drills are an indispensable tool for economic growth.

Power Transmission: Different advantages of power transmission based on requirements of drilling applications

Electrical power transmission systems for blast hole drills utilize electric motors as the primary power source to drive the drilling equipment. Electric power transmission systems are preferred for their efficiency, reduced operating costs, and environmental friendliness due to less dependency on fossil fuels. Hydraulic power transmissions rely on the pressurized flow of fluids to convert engine power into motion for operating blast hole drills making them suitable for handling tough drilling conditions. Mechanical power transmissions use gears, chains, or belts to transfer engine power to the drilling equipment and are relatively simple, cost-effective, and easier to maintain than electrical or hydraulic systems.

Type: Significance of drilling range for drilling applications

The large-range drilling rig is designed for high-capacity drilling operations in the mining, quarrying, and construction industries. Large-range drilling rigs are preferred when there is a need for high production rates, greater depth penetration, and extreme durability in the mining industry. Mid-range drilling rigs are versatile machines suitable for various industrial applications featuring smaller footprints compared to large-range rigs and provide sufficient power and stability for medium-depth drilling operations.

Drilling Method: high penetration rates and drilling accuracy based on drilling methods.

Down-The-Hole (DTH) drilling is a versatile and efficient method used predominantly in mineral exploration, water well drilling, and blasting holes for construction purposes. Rotary drilling rotates a drill bit while applying pressure to break through rock formations for industries such as oil & gas exploration and geothermal energy production. Top hammer drilling is commonly employed in quarrying operations, blast hole production for civil construction, and surface mining. Top hammer drilling is preferred in applications where rapid drilling rates are required in moderately hard and non-abrasive rock formations.

Application: Introduction of advanced drilling solutions across end-use industries

In the construction and infrastructure sector, blast hole drills are essential for various tasks, including excavation, foundation work, and tunneling. The rapid urbanization and expansion of transportation networks globally drive the need for high-performance drilling machines in the construction and infrastructure sectors. The open-pit mining industry relies heavily on blast hole drills to extract valuable minerals from the earth. Efficiency and productivity gains are crucial in open-pit mining as mining operators strive to optimize their operations while minimizing environmental impact.

Mode of Operation: Operation types to meet diverse project requirements.

Automatic blast hole drills are technologically advanced equipment that allow operators to automate drilling operations, resulting in increased efficiency and reduced human intervention. Automatic blast hole drills are preferred in large-scale mining operations where high production rates and accuracy are required. The automation features help minimize the impact of human error and increase the overall safety of the drilling process. Manual blast hole drills are operated directly by an operator controlling the drilling process based on visual cues and experience. Manual blast hole drills are more suitable for small-scale mining or construction projects due to their lower initial cost and simpler operation than automatic drills.

Regional Insights:

In the Americas, factors such as the development of infrastructure projects and a surge in mining activities contribute to the increase in demand for blast hole drills. Market players such as Caterpillar and Epiroc offer advanced drilling solutions that improve operational efficiency and reduce costs, contributing to the region's market growth. Rapid industrialization and urbanization drive significant investments in the construction and mining sectors in the APAC region. Countries including China, India, and Australia are witnessing a high demand for blast hole drills due to large-scale mining operations targeting base metals, coal, and precious metals. In addition, government initiatives promoting sustainable mining practices result in technological advancements in blast hole drill manufacturing in this region. The blast hole drills market has been steadily growing in EMEA due to expanding construction activities in developing countries of Eastern Europe and Africa. The Middle East also provides substantial opportunities for market growth, with its rich mineral reserves requiring advanced drilling equipment.

FPNV Positioning Matrix:

The FPNV Positioning Matrix is essential for assessing the Blast Hole Drills Market. It provides a comprehensive evaluation of vendors by examining key metrics within Business Strategy and Product Satisfaction, allowing users to make informed decisions based on their specific needs. This advanced analysis then organizes these vendors into four distinct quadrants, which represent varying levels of success: Forefront (F), Pathfinder (P), Niche (N), or Vital(V).

Market Share Analysis:

The Market Share Analysis offers an insightful look at the current state of vendors in the Blast Hole Drills Market. By comparing vendor contributions to overall revenue, customer base, and other key metrics, we can give companies a greater understanding of their performance and what they are up against when competing for market share. The analysis also sheds light on just how competitive any given sector is about accumulation, fragmentation dominance, and amalgamation traits over the base year period studied.

Key Company Profiles:

The report delves into recent significant developments in the Blast Hole Drills Market, highlighting leading vendors and their innovative profiles. These include Atlas Copco AB, BAUER Maschinen GmbH, Beijing Jincheng Mining Technology Co., Ltd., Blast Hole Bit Company, LLC, Boart Longyear Company, Caterpillar Inc., Center Rock, Inc., Doofor Inc., Doosan Corporation, Epiroc AB, Furukawa Rock Drill Co.,Ltd., Gaode Equipment Co., Ltd., Gill Rock Drill Company Inc., Herrenknecht AG, Hitachi Construction Machinery Co. Ltd., KGR Group, KLR Industries Limited, Komatsu Ltd., Mincon Group plc, Mine Master Spółka z o.o., NANCHANG KAMACH MINING CO., LTD., Naugra, Numa Tool Company, Parker Hannifin Corporation, Revathi Equipment Limited, Robit PLC, ROCKMORE International, Inc., Sandvik AB, Schramm Inc., Sinosteel Equipment & Engineering (S.A) Co., Ltd., and ThyssenKrupp AG.

Inquire Before Buying @ https://www.360iresearch.com/library/intelligence/blast-hole-drills?utm_source=einpresswire&utm_medium=referral&utm_campaign=inquire

Market Segmentation & Coverage:

This research report categorizes the Blast Hole Drills Market in order to forecast the revenues and analyze trends in each of following sub-markets:

Based on Type, market is studied across Large-range Drilling Rig and Mid-range Drilling Rig. The Large-range Drilling Rig commanded largest market share of 57.35% in 2022, followed by Mid-range Drilling Rig.

Based on Mode of Operation, market is studied across Automatic and Manual. The Manual commanded largest market share of 77.65% in 2022, followed by Automatic.

Based on Power Transmission, market is studied across Electrical, Hydraulic, and Mechanical. The Hydraulic commanded largest market share of 46.65% in 2022, followed by Mechanical.

Based on Drilling Methods, market is studied across DTH Drilling, Rotary Drilling, and Top Hammer Drill. The DTH Drilling commanded largest market share of 44.81% in 2022, followed by Rotary Drilling.

Based on Application, market is studied across Construction & Infrastructure and Open-Pit Mining. The Open-Pit Mining commanded largest market share of 53.65% in 2022, followed by Construction & Infrastructure.

Based on Region, market is studied across Americas, Asia-Pacific, and Europe, Middle East & Africa. The Americas is further studied across Argentina, Brazil, Canada, Mexico, and United States. The United States is further studied across Alaska, Arizona, California, Georgia, Michigan, Missouri, Montana, Nevada, North Dakota, West Virginia, and Wyoming. The Asia-Pacific is further studied across Australia, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Taiwan, Thailand, and Vietnam. The Europe, Middle East & Africa is further studied across Denmark, Egypt, Finland, France, Germany, Israel, Italy, Netherlands, Nigeria, Norway, Poland, Qatar, Russia, Saudi Arabia, South Africa, Spain, Sweden, Switzerland, Turkey, United Arab Emirates, and United Kingdom. The Europe, Middle East & Africa commanded largest market share of 44.45% in 2022, followed by Asia-Pacific.

Key Topics Covered:

1. Preface

2. Research Methodology

3. Executive Summary

4. Market Overview

5. Market Insights

6. Blast Hole Drills Market, by Type

7. Blast Hole Drills Market, by Mode of Operation

8. Blast Hole Drills Market, by Power Transmission

9. Blast Hole Drills Market, by Drilling Methods

10. Blast Hole Drills Market, by Application

11. Americas Blast Hole Drills Market

12. Asia-Pacific Blast Hole Drills Market

13. Europe, Middle East & Africa Blast Hole Drills Market

14. Competitive Landscape

15. Competitive Portfolio

16. Appendix

The report provides insights on the following pointers:

1. Market Penetration: Provides comprehensive information on the market offered by the key players

2. Market Development: Provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets

3. Market Diversification: Provides detailed information about new product launches, untapped geographies, recent developments, and investments

4. Competitive Assessment & Intelligence: Provides an exhaustive assessment of market shares, strategies, products, certification, regulatory approvals, patent landscape, and manufacturing capabilities of the leading players

5. Product Development & Innovation: Provides intelligent insights on future technologies, R&D activities, and breakthrough product developments

The report answers questions such as:

1. What is the market size and forecast of the Blast Hole Drills Market?

2. Which are the products/segments/applications/areas to invest in over the forecast period in the Blast Hole Drills Market?

3. What is the competitive strategic window for opportunities in the Blast Hole Drills Market?

4. What are the technology trends and regulatory frameworks in the Blast Hole Drills Market?

5. What is the market share of the leading vendors in the Blast Hole Drills Market?

6. What modes and strategic moves are considered suitable for entering the Blast Hole Drills Market?

Read More @ https://www.360iresearch.com/library/intelligence/blast-hole-drills?utm_source=einpresswire&utm_medium=referral&utm_campaign=analyst

Mr. Ketan Rohom

360iResearch

+1 530-264-8485

ketan@360iresearch.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.