The Rise of Off-Site Building Solutions Revolutionizing North America Construction

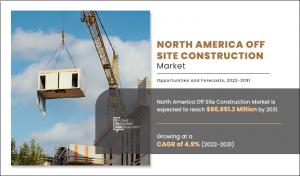

North America Off Site Construction Market Expected to Reach $80.8 Billion by 2031

PORTLAND, OR, UNITED STATES, June 1, 2023/EINPresswire.com/ -- Off-site construction, also known as modular construction or prefabrication, is a construction method that involves the manufacturing and assembly of building components or entire structures in a controlled factory environment, away from the actual construction site. These components are then transported to the site and installed to complete the construction process.

Commonly materials used in off-site construction include steel, wood, concrete, and others. Among these, the steel segment accounted for the highest market share in 2021, owing to its easy fabrication and ease in installation. In addition, the market is analyzed across different end-user industries of off-site construction including residential, data center, renewable energy, manufacturing, and commercial. The market is mainly driven by rise in advantageous features of off-site construction including reduction of waste, possibilities for circular economy, superior product quality and better health, and safety for workers. However, high initial cost involved in setting-up of off-site construction fabrication facilities and structural limitations of prefabricated modules constrain growth of the market.

Download Sample Report: https://www.alliedmarketresearch.com/request-sample/32155

In the context of North America, off-site construction has gained significant attention and popularity in recent years due to its numerous advantages. Some key benefits of off-site construction in North America include:

Time and Cost Efficiency: Off-site construction can significantly reduce project timelines since various building components are fabricated simultaneously, allowing for parallel construction processes. Additionally, the controlled factory environment minimizes the impact of weather delays, further speeding up construction. The time saved translates into cost savings, as labor and financing expenses are reduced.

Improved Quality Control: Factory-based construction ensures consistent quality control measures and adherence to predetermined standards. The controlled environment allows for rigorous inspections and testing, resulting in higher-quality building components. Off-site construction also reduces the risk of on-site errors and rework, enhancing overall construction quality.

Sustainability: Off-site construction promotes sustainability through reduced waste generation, enhanced resource efficiency, and improved energy performance. The factory environment enables better management of construction materials, minimizing waste generation and optimizing material usage. Additionally, the controlled environment facilitates the integration of sustainable design principles and technologies into building components.

Reduced Disruption: Off-site construction reduces on-site disruption, noise, and inconvenience to the surrounding community. Since the majority of construction activities occur in a factory setting, noise, dust, and traffic congestion associated with traditional construction are significantly reduced.

Design Flexibility: Off-site construction allows for design flexibility and customization. Building components can be engineered and manufactured to meet specific design requirements, allowing architects and designers to incorporate innovative and unique elements into their projects.

Addressing Skilled Labor Shortages: The construction industry in North America has been facing a shortage of skilled labor. Off-site construction mitigates this challenge to some extent by relying on factory workers who possess specialized skills and can be trained more efficiently than on-site construction workers. This can help alleviate the burden on traditional on-site construction crews.

Adaptability and Repurposing: Modular construction lends itself to adaptability and repurposing. The ability to manufacture building components that can be easily disassembled, relocated, or repurposed provides flexibility for future modifications or expansion of structures.

Purchase Inquiry: https://www.alliedmarketresearch.com/connect-to-analyst/32155

Top Players:

Key companies profiled in the North America off-site construction market report include Blokable Inc., Blu Homes, Emagispace, Falcon Structures, FullStack Modular, Modus Structures Inc, Nomodic, Plant Prefab, Inc., Project Frog, and SG Blocks Inc.

However, various businesses in the North America off-site construction market had to stop their business during the pandemic. This break directly impacted sales of companies involved in the North America off-site construction market. In addition, lack of manpower and raw materials constricted supply of raw materials for manufacturing various off-site construction components; and negatively influenced growth of the market. However, after two years of COVID-19 outbreak and introduction of vaccinations, severity of the pandemic has significantly reduced and key players in the market are recovering rapidly.

In North America, off-site construction has been applied to various building types, including residential homes, commercial buildings, schools, healthcare facilities, hotels, and even multi-story structures. The adoption of off-site construction methods continues to grow as more stakeholders recognize its benefits and seek innovative solutions to address construction challenges.

Buy This Research Report @ https://www.alliedmarketresearch.com/checkout-final/9d9bfeff862d02fe99acf9ab0d543ec1

David Correa

Allied Analytics LLP

+ 1-800-792-5285

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.