RASIRC Study Shows Hydrogen Plasma Damage Minimized by Hydrogen Peroxide Gas

Use of Hydrogen Plasma in Area Selective Deposition Now Possible

Secondary chemistries like hydrogen peroxide and hydrazine gas help simplify recipes when used along with precursors and plasmas for selective deposition and etch processes.”

SAN DIEGO, CA, UNITED STATES, April 13, 2022 /EINPresswire.com/ -- A recent study by RASIRC shows that H2O2 doping during hydrogen plasma exposure substantially protected oxide layers while metal or organic layers were processed. This finding supports the use of hydrogen plasma and hydrogen peroxide gas in area selective deposition applications that otherwise risked oxide layer damage. This could reduce step count, cleaning, and process variables. Results of the study will be presented at ASD 2022 in San Francisco.— Jeffrey Spiegelman, RASIRC Founder and CEO

Hydrogen Plasma is used to create energy and a reducing environment for growth of ALD metals, nitrides, and selective removal of surface species. Use in area selective deposition applications has been problematic due to oxide layer damage caused by hydrogen plasma and associate hydrogen radicals. Process engineers must provide a masking layer for adjacent oxide surfaces to prevent damage. This adds steps, costs, and risk of contamination and structure damage.

“Process recipes are increasingly complicated, moving from simple ALD recipes to intermediate steps to protect layers or otherwise modify the process,” said RASIRC Founder and CEO Jeffrey Spiegelman. “Secondary chemistries like hydrogen peroxide and hydrazine gas help simplify recipes when used along with precursors and plasmas for selective deposition and etch processes.”

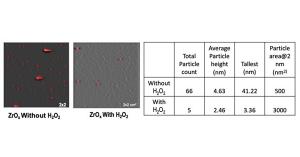

The RASIRC study shows that H2O2 doping in hydrogen plasma resulted: in 90 percent reduction in particle count and largest particle size; reduced rates of both particle agglomeration; and reduced surface roughing. H2O2 doping also prevented base Si wafer exposure.

Details on the research will be presented at ASD 2022, held April 20-22, 2022 in San Francisco, CA.

About RASIRC

RASIRC transforms liquids into dynamic gases that power process innovation in semiconductor and adjacent markets. By commercializing molecules for lower temperature processes, RASIRC patented technology enables the manufacture of atomic-scale oxides, nitrides, and metals. Innovative products such as BRUTE® Peroxide, BRUTE Hydrazine, the Peroxidizer®, and Rainmaker® Humidification Systems are being used to develop solutions for 5G, AI, IOT, and advanced automation.

What makes RASIRC a unique industry leader is our technical expertise and commitment to solving complex industry challenges for our customers. Our team of industry experts has a proven track record of being first to market by efficiently delivering state of the art technology that reduces cost, improves quality, and dramatically improves safety. With our customers at the forefront of all we do, we continue to research, develop, and design innovative products that purify and deliver ultra-pure gas from liquids for the semiconductor and related markets. Contact RASIRC to help solve your complex problems.

Jeffrey Spiegelman

RASIRC

+1 858-259-1220

jeff@rasirc.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.