RASIRC Study Shows Nitride Film Growth at 225°C with Hydrazine

Hydrazine outperforms Ammonia and demonstrates viability of TMS as aluminum source

Hydrazine overcomes the thermal limitations of ammonia without detrimental oxygen incorporation. This will enable both barrier layers and thermally conductive films.”

SAN DIEGO, CA, UNITED STATES, March 15, 2022 /EINPresswire.com/ -- RASIRC research shows that aluminum nitride can be grown thermally at 225°C without detrimental oxygen incorporation. The resulting paper is one of the first published demonstrating this ability, which will be useful for memory and logic devices as well as future semiconductor manufacturing. The research was conducted in conjunction with Professor Jiyoung Kim and the University of Texas—Dallas (UTD), which is at the forefront of ALD for next generation device process development.— Jeffrey Spiegelman, RASIRC Founder and CEO

This paper is the first of a series of papers looking at growth of Aluminum Nitride with hydrazine at low temperature. Further studies at University of California San Diego (UCSD) and UTD show how thermal ALD films can be further improved by adding a plasma step within the ALD process to create an ALA or atomic layer anneal to generate films that are superior to both ALD and PEALD for conformality and WER (wet etch rate).

“Hydrazine overcomes the thermal limitations of ammonia without detrimental oxygen incorporation,” said RASIRC Founder and CEO Jeffrey Spiegelman. “This will enable both barrier layers and thermally conductive films.”

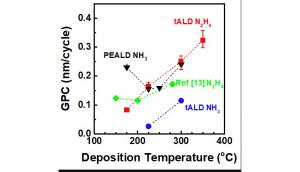

Research results showed that a high growth rate can be achieved compared to NH3 as the nitrogen source due to the high reactivity of N2H4. XPS results showed an Al:N ratio of 1:1.1 and few impurities in the films. Stable AlN thin films were successfully grown while the material parameters were comparable to those of aluminum nitride films deposited using NH3. In addition, the rapid deposition rate at low temperatures demonstrates the potential of the nitrogen source to replace NH3.

The paper “Low Temperature Thermal Atomic Layer Deposition of Aluminum Nitride Using Hydrazine as the Nitrogen Source” is available as part of the “Atomic Layer Deposition Technique in Material Science” special issue.

BRUTE Hydrazine

BRUTE Hydrazine enables uniform nitride deposition for titanium and early transition metals at low temperature. BRUTE Hydrazine may also be used as an atomic hydrogen source, where metals such as Ru, Cu, and Co may be cleaned and reduced. BRUTE Hydrazine has been formulated with a higher flash point for safer handling.

About RASIRC

RASIRC transforms liquids into dynamic gases that power process innovation in semiconductor and adjacent markets. By commercializing molecules for lower temperature processes, RASIRC patented technology enables the manufacture of atomic-scale oxides, nitrides, and metals. Innovative products such as BRUTE Peroxide, BRUTE Hydrazine, the Peroxidizer®, and Rainmaker® Humidification Systems are being used to develop solutions for 5G, AI, IOT, and advanced automation.

What makes RASIRC a unique industry leader is our technical expertise and commitment to solving complex industry challenges for our customers. Our team of industry experts has a proven track record of being first to market by efficiently delivering state of the art technology that reduces cost, improves quality, and dramatically improves safety. With our customers at the forefront of all we do, we continue to research, develop, and design innovative products that purify and deliver ultra-pure gas from liquids for the semiconductor and related markets. Contact RASIRC to help solve your complex problems.

Jeffrey Spiegelman

RASIRC

+1 858-259-1220

jeff@rasirc.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.