Modix Announces new add-ons: New Print Head, Firmware & Improved User Experience

TEL AVIV, ISRAEL, March 1, 2022 /EINPresswire.com/ -- Modix (https://modix3d.com), a leading global developer of large format 3D printers announces the availability of new add-ons to its line of large format 3d printers. These add-ons will improve the core performance and capabilities of its full line of 3D printers. The new add-ons are available for pre-orders for both new and existing owners of Modix 3D printers. Pricing and lead time details are available at: https://www.modix3d.com/add-ons-february-2022

The add-ons include:

New Print-Head

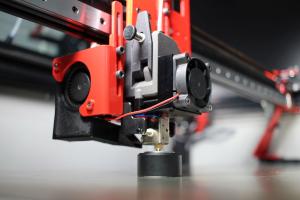

Modix is proud to announce its new print-head design, “Griffin”. The new print-head consists of a custom extruder made by Bondtech (based on the BMG model) and of a new hotend designed by Modix. The new design consists of the following improvements:

• Higher flow rate & higher printing temperatures: The new and more powerful extruder provides a double drive-gear system that grabs the filament from both sides. The heat-block is made of nickel coated copper, for a faster heat transfer and compatibility with higher printing temperatures. The design includes the advanced Slice Engineering Bi-Metal heat-break that extends the melting zone inside the heat-block by being mostly made of copper as well. In addition, an upgraded PT-1000 temperature sensor will enable printing in higher temperatures of up to 500°c. An optional water based hot-end cooler will also enhance the capability of printing in hot environments (will be available at a later stage).

• Higher reliability: Large scale 3D printing usually involves the risk of the print-head scratching or crashing into the thick layer models resulting in bent or broken heat-breaks. The new print-head provides a rigid mounting of the heat-block, so it’s naturally more reliable and reduces these situations. The main reason for this is that the heat-block is now mounted on three faces instead of only one. It can withstand a much stronger impact thanks to this additional bracing. The longer-type E3D SuperVolcano can also be attached to the rigid mounting as well, using a dedicated adapter.

• Improved User Experience: The new print-head design makes nozzle replacements much easier, and even allows a quick swapping of the entire filament melting subsystem. The rigid mounting of the heat-block allows one handed nozzle replacement, making it even easier to test different nozzle diameters.

• Easy Swap: The design of the mounting bracket and the D shaft style of the Slice Engineering heat-break gives users the ability to slide the entire filament melting subsystem in and out with ease. This will allow users to dedicate a complete setup for a specific filament type. i.e. keeping one setup for abrasive carbon filled filament and another one for prototyping with PLA.

• Compact Design: The new design maintains the previous design benefits of compact design that preserves the generous Z-axis travel and is compatible with the vast offering of E3D Volcano nozzles coming in numerous sizes and materials.

• Smart: The new print-head allows automatic Z off-set calibration between the nozzle and the BL Touch probe. This is by far easier and more precise than the manual procedure. A dedicated sensor allows the BLTouc h and the nozzle to touch the surface, consequently. The precise relative distance (the "offset") is saved automatically to the printer.

The new print head demo video: https://www.youtube.com/watch?v=gdyH43QjHdM

Video of the smart Z-offset calibration: https://www.youtube.com/watch?v=gvwfQ_r7xoU

New firmware

Modix also announces the availability of the next generation firmware – RepRap Firmware Version 3 (RRF3) Made by the Duet team. This firmware update provides a whole new level of smart capabilities. The conditional G-code based macros plus the real time monitoring engine enhance both reliability and user experience. The printers can now react to complex dynamic situations during calibration and printing scenarios. In addition, it presents a new level of connectivity and expandability.

Tilt Screen

The tilt screen is a 'convenience' improvement, mainly in our tallest machines: Modix BIG-Meter and Modix-120Z.

Emergency Reset Button

Together with the tilt screen update, a new emergency reset (software reset) button is now located on the front of the machine. This control and safety feature will allow you to immediately stop prints whenever needed.

Heavy Spools Mounting Shelf

A refreshed design of the spool mounting shelf will now enable mounting 8KG spools instead of only 5KG spools. No need for frequent filament handling.

Mr. Shachar Gafni, Modix CEO: "Modix continues its journey to become a market leader by presenting both high-end technology and convenient user experiences. Only three months after we have presented six new important add-ons we are proud to present additional fruits of our dedicated R&D efforts made throughout 2021.“

About Modix:

Modix is a Tel-Aviv based developer of large format 3D printers. Modix 3D printers are based on cherry-picked, heavy duty premium components providing reliability and high-quality prints for end users.

For sales inquiries please contact: sales@modix3d.com

The add-ons include:

New Print-Head

Modix is proud to announce its new print-head design, “Griffin”. The new print-head consists of a custom extruder made by Bondtech (based on the BMG model) and of a new hotend designed by Modix. The new design consists of the following improvements:

• Higher flow rate & higher printing temperatures: The new and more powerful extruder provides a double drive-gear system that grabs the filament from both sides. The heat-block is made of nickel coated copper, for a faster heat transfer and compatibility with higher printing temperatures. The design includes the advanced Slice Engineering Bi-Metal heat-break that extends the melting zone inside the heat-block by being mostly made of copper as well. In addition, an upgraded PT-1000 temperature sensor will enable printing in higher temperatures of up to 500°c. An optional water based hot-end cooler will also enhance the capability of printing in hot environments (will be available at a later stage).

• Higher reliability: Large scale 3D printing usually involves the risk of the print-head scratching or crashing into the thick layer models resulting in bent or broken heat-breaks. The new print-head provides a rigid mounting of the heat-block, so it’s naturally more reliable and reduces these situations. The main reason for this is that the heat-block is now mounted on three faces instead of only one. It can withstand a much stronger impact thanks to this additional bracing. The longer-type E3D SuperVolcano can also be attached to the rigid mounting as well, using a dedicated adapter.

• Improved User Experience: The new print-head design makes nozzle replacements much easier, and even allows a quick swapping of the entire filament melting subsystem. The rigid mounting of the heat-block allows one handed nozzle replacement, making it even easier to test different nozzle diameters.

• Easy Swap: The design of the mounting bracket and the D shaft style of the Slice Engineering heat-break gives users the ability to slide the entire filament melting subsystem in and out with ease. This will allow users to dedicate a complete setup for a specific filament type. i.e. keeping one setup for abrasive carbon filled filament and another one for prototyping with PLA.

• Compact Design: The new design maintains the previous design benefits of compact design that preserves the generous Z-axis travel and is compatible with the vast offering of E3D Volcano nozzles coming in numerous sizes and materials.

• Smart: The new print-head allows automatic Z off-set calibration between the nozzle and the BL Touch probe. This is by far easier and more precise than the manual procedure. A dedicated sensor allows the BLTouc h and the nozzle to touch the surface, consequently. The precise relative distance (the "offset") is saved automatically to the printer.

The new print head demo video: https://www.youtube.com/watch?v=gdyH43QjHdM

Video of the smart Z-offset calibration: https://www.youtube.com/watch?v=gvwfQ_r7xoU

New firmware

Modix also announces the availability of the next generation firmware – RepRap Firmware Version 3 (RRF3) Made by the Duet team. This firmware update provides a whole new level of smart capabilities. The conditional G-code based macros plus the real time monitoring engine enhance both reliability and user experience. The printers can now react to complex dynamic situations during calibration and printing scenarios. In addition, it presents a new level of connectivity and expandability.

Tilt Screen

The tilt screen is a 'convenience' improvement, mainly in our tallest machines: Modix BIG-Meter and Modix-120Z.

Emergency Reset Button

Together with the tilt screen update, a new emergency reset (software reset) button is now located on the front of the machine. This control and safety feature will allow you to immediately stop prints whenever needed.

Heavy Spools Mounting Shelf

A refreshed design of the spool mounting shelf will now enable mounting 8KG spools instead of only 5KG spools. No need for frequent filament handling.

Mr. Shachar Gafni, Modix CEO: "Modix continues its journey to become a market leader by presenting both high-end technology and convenient user experiences. Only three months after we have presented six new important add-ons we are proud to present additional fruits of our dedicated R&D efforts made throughout 2021.“

About Modix:

Modix is a Tel-Aviv based developer of large format 3D printers. Modix 3D printers are based on cherry-picked, heavy duty premium components providing reliability and high-quality prints for end users.

For sales inquiries please contact: sales@modix3d.com

Media Relations

Modix

+972-584-486-725

info@modix3d.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.