RASIRC Survey of Hydrazine (N2H4) in Semiconductor Applications Shows Growing Activity in Thin Films at Low Temperature

Hydrazine Addresses Increasing Need for More Reactive Nitrogen Sources

This survey paper provides references for process engineers and scientists looking for information on how different nitride films can be grown with hydrazine in low temperature applications.”

SAN DIEGO, CA, UNITED STATES, February 23, 2022 /EINPresswire.com/ -- RASIRC today published a survey of semiconductor and related applications that use hydrazine gas. The growing interest in hydrazine is driven by a need for new metals and metal nitride films that meet lower thermal budgets and shrinking 3-dimensional structures. These were previously met by films grown with ammonia, but no longer meet today’s requirements for metal-nitride films. A new formulation of hydrazine meets these requirements for semiconductor manufacturing, driving renewed interest in early studies and new research activities in low temperature thin film growth.— Jeffrey Spiegelman, RASIRC Founder and CEO

“Hydrazine is emerging as a replacement for ammonia and nitride plasma in low temperature applications,” said RASIRC Founder and CEO Jeffrey Spiegelman. “This survey paper provides references for process engineers and scientists looking for information on how different nitride films can be grown with hydrazine.”

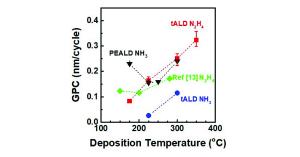

Many applications now require more reactive nitrogen sources. Each application has different materials, metals, thicknesses, electrical requirements, temperature constraints, purity needs, and economic targets. Emerging devices such as Logic and Advanced Memory require high quality thin (5-20 Å) electrode and barrier films, creating difficult thermal budget constraints. III-V Nitride devices require lower deposition temperatures and compositional stability. Several late transition-metals also benefit from hydrazine as a reducing agent where hydrazine can act as a surface cleaning agent or a co-reactant for metal ALD.

The RASIRC survey includes primary references for areas of hydrazine ALD/CVD relevant to Semiconductor device applications as well as related films. More in-depth discussion is provided for specific films—Titanium Nitride (TiN), Silicon Nitride (SiN), Gallium Nitride (GaN), and Indium Gallium Nitride (InGaN). In addition, there is discussion of Copper, Cobalt, and Ruthenium reduction in situ by hydrazine.

The survey paper “The Emergence of Hydrazine (N2H4) in Semiconductor Applications” is available on the RASIRC website.

BRUTE Hydrazine

BRUTE Hydrazine® enables uniform nitride deposition for titanium and early transition metals at low temperature. BRUTE Hydrazine may also be used as an atomic hydrogen source, where metals such as Ru, Cu, and Co may be cleaned and reduced. Brute Hydrazine has been formulated with a higher flash point for safer handling.

About RASIRC

RASIRC transforms liquids into dynamic gases that power process innovation in semiconductor and adjacent markets. By commercializing molecules for lower temperature processes, RASIRC patented technology enables the manufacture of atomic-scale oxides, nitrides, and metals. Innovative products such as BRUTE Peroxide, Brute Hydrazine, the Peroxidizer®, and Rainmaker® Humidification Systems are being used to develop solutions for 5G, AI, IOT, and advanced automation.

What makes RASIRC a unique industry leader is our technical expertise and commitment to solving complex industry challenges for our customers. Our team of industry experts has a proven track record of being first to market by efficiently delivering state of the art technology that reduces cost, improves quality, and dramatically improves safety. With our customers at the forefront of all we do, we continue to research, develop, and design innovative products that purify and deliver ultra-pure gas from liquids for the semiconductor and related markets. Contact RASIRC to help solve your complex problems.

Jeffrey Spiegelman

RASIRC

858 259 1220

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.