How Tesla and Boron Improves Performance

Tesla improves performance using strategic minerals - lithium in batteries, boron in neodymium magnets, and boron for lighter, stronger frames.

HONG KONG, January 2, 2022 /EINPresswire.com/ -- Tesla manufactures electric cars and battery energy storage from home to grid-scale, solar panels, solar roof tiles, and other related products and services. With a market capitalization of almost $1 trillion, Tesla is one of the most valuable automobile manufacturers globally. It uses lithium – battery – and boron – neodymium magnets – to deliver alternative energy sources and boron to provide a lighter, more muscular frame.Tesla’s work revolves around automotive, energy generation, and storage in the industry sector. Tesla uses lithium and boron to power its cars. Tesla does not use traditional methods to get energy. Lithium-ion batteries are lighter than other battery types for electric vehicles. The neodymium magnets in its powertrain contain boron. In Addition, Tesla manufactures battery energy storage from home to grid-scale, solar panels, and solar roof tiles.

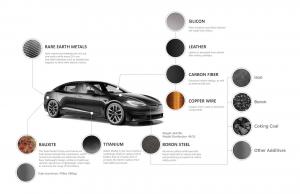

Tesla Relies on Extraordinary Materials - image sources: adapted from https://www.visualcapitalist.com/extraordinary-raw-materials-in-a-tesla-model-S -. Critics have praised the car’s safety rating, range, and design. However, it is also worth considering that the incredible materials used in the Tesla Model S help make all things possible.

The Tesla battery pack weighs 1,200 lbs (540 kg), equal to about 26% of the car’s total weight. At 44.5 centimeters off the ground, the car’s center of gravity is at its lowest point ever. The battery itself contains 7,104 lithium-ion battery cells.

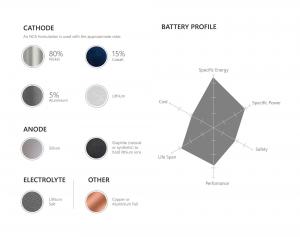

Model S batteries are made of NCA cathodes, with a nickel/cobalt/aluminum ratio of about 80% nickel, 15% cobalt, and 5% aluminum. The cathode also contains a small amount of lithium. Graphite is used as an anode to hold lithium ions. Silicon is also used in the anode in small amounts. Lithium salt is the electrolyte. In addition to copper, aluminum foil is used in the battery.

The two materials, NCA and NMC, have related structures with similar electrochemical behaviour and identical performance. Witness the relatively high energy densities and relatively high performance. It is estimated that the NCA battery of Model 3 contains between 4.5 and 9.5 kg of cobalt and 11.6 kg of lithium.

The powertrain uses Boron-powered Neodymium Magnets. A Neodymium magnet is a type of permanent magnet that uses the power of neodymium (NdfeB), one of the strongest substances known. Neodymium magnets act as the stator or part of a traditional electric motor that does not move. These magnets have more advantages than other types of magnets, especially in high-performance motors or where reducing size is a crucial factor. Bearing in mind that all new technologies aim at reducing the overall size of the product, it is likely that these engines will soon take over the whole market.

Neodymium magnets are increasingly used in the automotive industry, and have become the preferred option for designing new magnetic applications for this sector. In electric motors, neodymium magnets perform better when the motors are smaller and lighter.

From the engine that spins a DVD to the wheels of a hybrid car, neodymium magnets are used throughout the vehicle. A neodymium magnet with a low degree of coercivity may lose strength if heated to more than 80°C. High coercivity neodymium magnets have been developed to operate at temperatures up to 220°C, with slight irreversible loss. The need for a low-temperature coefficient in neodymium magnet applications has led to several grades to meet specific operational requirements.

Tesla focuses on research and development. Its critical engineering and design activities help support its new product development. The organization uses intense research and development to produce fresh and innovative products in powertrain technology. Tesla also has the upper hand in vehicle engineering, innovative manufacturing, and energy storage. Its powertrain and battery pack feature a modular design. This helps the vehicles from the future generation to integrate with this technology.

Tesla Model S’s body and chassis are made from aluminum. We get aluminum mostly from bauxite ore. The lightweight aluminum helps increase the battery’s range much more than the other electric vehicles. Boron plays a critical role in reinforcing the aluminum here. High-strength boron steel is also required at critical points of safety. Iron, boron, coking coal, and other additives are the main components of boron steel.

In Tesla Model 3 and Tesla Model X, we can find LiNi, Lithium Nickel. With a few exceptions, current electric cars, as of 2019, use either NCA or lithium nickel manganese cobalt oxides.

Silicon is used in Glass windows and other features in the Tesla EV Cars. Silicon, otherwise known in its chemical form as Silicon dioxide, is the second most abundant element on the surface of the Earth and is used in a lot of modern-day electric cars. Silicon is cheaper than similar products such as Indium and Gallium.

There is a focus in the industry on redesigning cars, buses, and HGVs using lithium-ion batteries as part of a Road to Zero strategy. Conversations centre on whether there are sufficient lithium and cobalt resources to replace the two billion vehicles running on petrol/diesel. However, there may also be a better solution using boron and hydrogen.

Boron is plentiful with billion tonnes of reserves in Turkey alone, in comparison to 15 million tonnes of lithium worldwide. And there is no shortage of hydrogen. Boron-hydrogen fusion is the new open secret. It has become a possibility in recent times with the invention of the Chirped Pulse Amplification laser in 2018.

Musk says that Tesla was founded to accelerate the transition to sustainable transport and energy. This can be achieved through solar power and electric vehicles.Lithium-ion batteries also have more storage capacity than the lead-acid batteries used by other manufacturers. Tesla’s design enables them to perform at high speeds while maintaining safety standards.

Two main features work in favour of boron. Initially, it does not release any radioactive waste. Secondly, it can produce electricity directly. The vehicles need electrons to neutralize their change. Electric current is pushed via a circuit similar to the drive motors of a vehicle. Even though the technology seems far away, we may see cars using boron hydrogen fusion on the road in the next decade.

Brendan McMahon

BORATES TODAY

hello@borates.today

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.