Electro Scan Announces Results for 14-Mile Gravity Sewer Main Benchmark Comparing CCTV v. FELL Inspection

Wondering why CCTV is not providing you actionable intelligence to reduce or eliminate infiltration? Read results from the just released study.

Pinpoint leak detection allows 3/8" (1cm) locational accuracy with each defect expressed in Gallons per Minute or Liters per Second.

Inspection By Same National Pipeline Contractor Shows Dramatic Differences Assessing Cured-In-Place Pipe (CIPP) & Tap Connections, Including CCTV Operator Bias

SACRAMENTO, CALIFORNIA, USA, November 18, 2020 /EINPresswire.com/ -- Electro Scan Inc. announced results today for a 14-mile (22.5-kilometer) North American pipeline benchmark leakage study, comparing Closed-Circuit Television (CCTV) inspection against Focused Electrode Leak Location (FELL) inspection.CCTV results used the National Association of Sewer Service Companies (NASSCO) Pipe Assessment Certification Program (PACP) codes to identify pipeline defects.

FELL inspection results were completed in accordance with ASTM F2550, Standard Practice for Locating Leaks in Sewer Pipes By Measuring the Variation of Electric Current Flow Through the Pipe Wall.

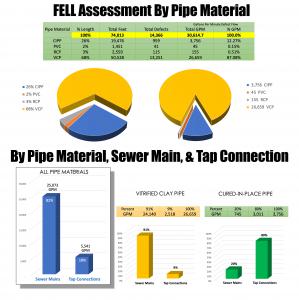

The project was conducted between August 2019 and March 2020, which assessed 322 gravity sewer mains, totaling 74,000 linear feet (LF), and included over 1,800 customer tap connections to the sewer mains.

Pipe diameters ranged from 8 to 12 inches for nearly 90% of the study area, while the remaining sewer main sizes varied up to 27 inches in diameter.

The study's primary purpose was to directly compare CCTV and FELL inspection results with respect to documenting infiltration sources in sewers mains for this utility that is operating under an Environmental Protection Agency Consent Decree.

The company notes that this study is the first major evaluation of its kind to identify infiltration sources by comparing the more conventional CCTV inspection results to the innovative FELL technique.

Importantly, FELL inspection quantified potential infiltration flow rates in Gallons per Minute (GPM) for all sewer mains defects, as well as at each tap connection. This is not true of CCTV inspection which, except for making estimates by operators from infiltration only if visible at the time of inspection, cannot quantify infiltration flow rates.

Municipal engineers and consultants that would like to read the Key Findings and Executive Summary of the study should visit the Case Study here. Additional details of this CCTV-FELL North American benchmark study may be requested by contacting Electro Scan Inc.

ABOUT ELECTRO SCAN INC.

Electro Scan Inc., a leading supplier of machine-intelligent pipeline assessment products and services for the water & wastewater market. Named to Government Technology’s esteemed 2020 GovTech 100 list for the second straight year, Electro Scan develops proprietary pipe condition assessment equipment, capable of delivering on module mobile electronic in-pipe platforms, supporting a cloud-based architecture that automatically locates, measures, and reports defects in new and existing sewer, water, and natural gas pipelines, typically not found by legacy inspection methods.

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.