American & British Water Utilities Adopt Electro Scan to Test New & Existing Trenchless Cured-In-Place Pipe (CIPP)

Hours apart, Electro Scan field crew members Mackenzie App in the United States and Brad Weston in the United Kingdom test Cured-In-Place Pipe (CIPP) showing the growing demand for machine-intelligent technology to test the watertightness of new and existing pipes.

Outdated Visual Inspection of Widely Used CIPP Being Replaced By Machine-Based Technology to Locate & Quantify Leaks Missed by CCTV Cameras

A few hours later in the United States, Mackenzie App, Field Services Manager, Electro Scan Inc., began scanning Cured-In-Place Pipe (CIPP), representing a trenchless method of pipe rehabilitation, demonstrating the growing demand for quality assurance testing of a widely used repair technique.

CIPP has enjoyed a long history in the municipal and utility construction industry without much quality assurance testing once the new pipe is installed underground.

In 1971, Eric Wood first implemented cured-in-place pipe technology in London, England, calling the process 'insitu form' derived from the Latin meaning "form in place". Granted a patent in 1977 the process entered the public domain in 1994, with the majority of lining contractors and suppliers only required to submit CCTV inspections without the requirement to test full-length 360-degree liners for watertightness.

Both UK and US Electro Scan CIPP surveys were performed in accordance with strict COVID-19 health & safety requirements finding and measuring leaks in Liters per Second and Gallons per Minute, respectively, with worldwide testing performed throughout the pandemic.

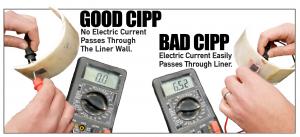

Missed by high resolution Closed-Circuit Television (CCTV) cameras, Electro Scan's patented and patent-pending technology provides truth-testing of lined pipes, including all pipe materials for gravity sewer mains, pressurized water mains, and force mains, called sewer rising mains outside of the United States.

While U.S. sewer and water utilities are adding Electro Scan's Focused Electrode Leak Location (FELL) into CIPP specifications as an acceptance requirement, UK water utilities just starting AMP7 are realizing the need to conduct quality assurance testing to provide environmentally resilient and sustainable piping networks.

Despite over a dozen start-ups looking to apply artificial intelligence and machine learning to help municipal utilities and consulting engineers to properly review hours of CCTV videos, the inability for CCTV cameras to tell superficial cracks from cracks that go through a pipe wall, evaluate inside the bell & spigot of joints, or evaluate the permeability of CIPP liners, created the need for a machine-intelligent solution that could give cost-effective unambiguous, unbiased, and uncontested test results.

"It's the dirty little secret of the industry that poorly cured or badly installed CIPP liners can leak," states Chuck Hansen, Chairman and Founder, Electro Scan Inc. "And, pipes can actually leak more after CIPP, if customer services are not properly restored."

In 2019, Electro Scan inspected over 110,000 LF of CIPP liners using its low voltage conductivity technology, locating over 14,000 leaks in trenchless liners, or approximately one leak every 8 feet.

More alarming, for the twelve months ending December 31, 2019, over 80% of CIPP liners inspected had measurable defects contributing to unwanted inflow and infiltration (I/I).

These results are up from 78% in the company's 2018 survey, with 44% of liners having leaks of more than 20 Gallons per Minute.

Electro Scan’s Focused Electrode Leak Location (FELL) technology has tested CIPP lining materials from over thirty (30) suppliers, worldwide.

Based on a recent online poll conducted as part of its Electro Scan’s Trenchless Technology Webinar held in March 2020, 35% of municipal agencies have had disputes with CIPP Contractors or issues with their liner after warranty expiration.

In addition to assessing newly lined sewer mains, directly after CIPP installation, Electro Scan's new multi-sensor probe for pressurized water mains and force mains is able to assess pressurized CIPP liners while in service and without customer interruption.

Problems with CIPP and the limitations for CCTV to accurately test liners have been well-documented.

In 2012, the USEPA published its 'Study Report Evaluation of CIPP In Municipal Gravity Sewers' (EPA 600 R-12 004_R), stating that municipal utilities could only identify deterioration or defects that were easily identified visually and that liner distortions were difficult to identify.

The USEPA also found significant differences testing CIPP liner coupons. In one city a CIPP liner reported a finished thickness of 7.5mm, while the EPA-funded study showed an average measured liner thickness of 5.72mm.

Last year, a paper presented at the 2019 North American Trenchless Technology conference, titled 'Addressing the Shortcomings of a Sampling Strategy in CIPP Quality Assurance Programs' stated "while CIPP technologies have improved, the ability of contractors to obtain more consistent quality installations has not yet been demonstrated."

"The impact of the coronavirus global pandemic has provided an unexpected pause for municipal governments to reassess their capital programs and make sure that necessary 'checks & balances' are in place to deliver the biggest bang-for-the-buck for constituents," states Carissa Boudwin, Vice President, Marketing.

According to co-authors Tony Araujo and Bruce Yao of Paragon Systems Testing (Concord, Ontario, Canada), "100% inspection reveals, that even with a very rigorous quality control regime, a significant percentage of CIPP liners will fail to meet specification requirements."

"We absolutely believe that trenchless rehabilitation and CIPP is an important tool for smart cities to maximize capital investments to deliver resilient and sustainable infrastructure programs," states Mike Condran, PE, Vice President, Electro Scan Inc.

"Unfortunately, legacy pipe inspection technologies have not offered unbiased and repeatable methods to assess full-length 360-degrees of pipelines for leaks," continues Condran.

Recently, a large metropolitan utility contracted with Electro Scan to conduct a detailed assessment of various pipe materials in areas known to have significant infiltration, with little to no defects identified by CCTV.

Not only did the company find significant defects in pre- and post-rehabilitated pipes, but Electro Scan was able to evaluate its recent CIPP liners showing defect patterns that were similar to liner defects at nine (9) other cities using CIPP from the same supplier.

Common defects found in CIPP liners include, but are not limited to:

- Accelerant Burns

- Accidental Cuts

- Bad Service Reconnections

- Bad Lateral Liners

- Blisters

- Delamination

- Defective Epoxy

- Equipment Damage

- Foreign Objects

- Lowered Resin to Felt Ratios

- Pinholes

- Poor, Incomplete, or Uneven Curing

- Overcooking

- Stretching

- Top-Hat Defects

- Wet-Out Failures

- Wrinkles, including Buckling, Fins, Folds, Lifts, & Ridges

Industry experts agree that a high percentage of liners are installed without curing them completely and cannot be validated for 50 year performance.

However, given Electro Scan's technology, owners and engineering consultants can identify defects within minutes of completing CIPP installation and restoring customer service laterals or taps.

Last year, Electro Scan updated its flow computations for pipe defects to more accurately document potential I/I by including pinhole leaks observed during inspection.

Revision to its industry standard leak detection technology was based on recommendations from German-based Institut für Unterirdische Infrastruktur (IKT), the world’s leading research organization specializing in wastewater pipes and trenchless rehabilitation.

Guided by both the American Society of Testing and Materials (ASTM) and the American Water Works Association (AWWA) standards, Electro Scan’s low voltage technology is the only approach to precisely locate pipe defects and quantify flow rates.

In fact, the AWWA M77 Manual of Practice for Condition Assessment of Water Mains identifies low voltage conductivity inspection as the only technology able to assess CIPP lined water mains for leaks.

ABOUT ELECTRO SCAN

Headquartered in Sacramento, Calif., the company designs, develops, and markets proprietary pipe condition assessment equipment, delivers field services, and offers cloud-based data processing and reporting applications that automatically locate, measure, and report defects typically not found using legacy inspection methods. In 2020, the company was named to Government Technology’s esteemed GovTech 100 list for the second year in row.

#cctv #cipp #conductivity #electroscan #fell #forcemain #insitu #leaklocation #nassco #rehabilitation #repairs #risingmain #sewer #trenchless #water #wrc

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Electro Scan's Multi-Sensor Probe for Finding Leaks in Pressurized Water Pipes and Sewer Force Mains

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.