Electro Scan Surpasses 1,500 Cured-In-Place Pipe (CIPP) Surveys Worldwide

Founded in 2011 by municipal software entrepreneur Chuck Hansen, Electro Scan Inc.'s worldwide headquarters are located in Sacramento, California, USA.

Attend a free webinar on April 29, 2020 at 10am Pacific, titled 'From Sewer Infiltration to Asset Rehabilitation – An End-to-End Roadmap for Action' hosted by Innovyze & Electro Scan. Inc.

Use of Low Voltage Electric Current & Cloud Reporting Allows Trenchless Pipe Installations to be Tested for Watertightness Within Minutes After Installation

Cured-In-Place Pipe (CIPP) is a trenchless rehabilitation method used to repair or replace existing sewer & water pipelines.

Used by municipal & investor-owned utilities for over 40 years, without requiring excavation to rehabilitate pipes, defects in these liners and customer re-connections have traditionally not been properly documented due to inherent limitations of visual inspection using Closed-Circuit Television (CCTV) cameras.

“We are proud to serve the worldwide water industry to provide governance & stewardship to help water utility owners achieve & maintain resilient infrastructure,” stated Chuck Hansen, Chairman & Founder, Electro Scan Inc.

Developed over six years ago to consolidate and analyze CIPP test results, Electro Scan Inc., in association with Hansen Analytics, LLC, maintains one of the largest databases of CIPP performance, tracked by agency, lining supplier, installation contractor, curing method, and lining material.

In 2019, Electro Scan inspected over 110,000 LF of CIPP liners using its patented low voltage conductivity technology, finding over 14,000 leaks in trenchless liners.

For the year ending December 31, 2019, over 80% of CIPP liners inspected had measurable defects contributing to unwanted inflow and infiltration (I/I).

These results are up from 78% in the company's 2018 survey, with 44% of liners having leaks of more than 20 Gallons per Minute.

Electro Scan’s Focused Electrode Leak Location (FELL) technology has tested CIPP lining materials from over thirty (30) suppliers, worldwide.

Last year, Electro Scan updated its flow computations for pipe defects to more accurately document potential I/I by including pinhole leaks observed during inspection.

Revision to its industry standard leak detection technology was based on recommendations from German-based Institut für Unterirdische Infrastruktur (IKT), the world’s leading research organization specializing in wastewater pipes and trenchless rehabilitation.

Guided by both the American Society of Testing and Materials (ASTM) and the American Water Works Association (AWWA) standards, Electro Scan’s low voltage technology is the only approach to precisely locate pipe defects and quantify flow rates.

In fact, the AWWA M77 Manual of Practice identifies this low voltage inspection as the only technology to assess CIPP lined water mains for leaks.

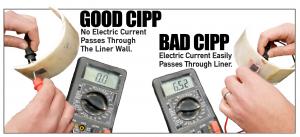

Providing accurate, fast, and repeatable test results, Electro Scan’s technology creates an electric circuit between the inside of a pipe and its surface-located base station.

If a leak exists, Electro Scan’s machine-intelligent probe measure the precise size of each pipe defect, and correlates the measurement to an estimated flow rate, reported in Gallons per Minute or Liters Per Second.

Electro Scan's first CIPP project resulting in the removal and relining of a project was in March 2014 in Williamsburg, Virginia.

Based on a recent online poll conducted as part of its Electro Scan’s Trenchless Technology Webinar held in March, 35% of municipal agencies have had disputes with CIPP Contractors or issues with their liner after warranty expiration.

Many Electro Scan surveys now are required before and after rehabilitation to quantify rehabilitation effectiveness.

While CIPP has been an effective tool to eliminate leaks at cracks and joints, some post-CIPP liners register higher defect flows after rehabilitation.

For instance, many customer tap connections (i.e. where a residential service laterals connects to the sewer main), do not have any leaks before rehabilitation; however, since lining a pipe will temporarily cover a customer’s lateral, the rotating blade used to cut through the liner and re-connect a customer’s pipe to the main, may accidentally damage the wall of the host pipe, making large defects or leaks where none existed, prior to rehabilitation.

Since Electro Scan’s FELL technology is able to provide defect flows before and after rehabilitation, agencies owning their own equipment or authorized service providers can provide percent reductions in flow, within minutes after completing repairs or renewals.

In contrast, municipalities traditionally must wait 1-3 years after rehabilitation, waiting for one or more similar-sized wet-weather events, that are neither specific to individual sewer mains or may not accurately measure infiltration levels due to equipment malfunctions, remote power or battery issues, or data errors.

On Wednesday, April 29, 2020, at 10:00AM Pacific Time, Innovyze & Electro Scan Inc. will co-host an online webinar titled 'From Sewer Infiltration to Asset Rehabilitation – An End-to-End Roadmap for Action,' discussing how Innovyze users worldwide can now access Electro Scan data, before and after pipeline rehabilitation projects to provide unparalleled quality assurance and quality control over CIPP lining and capital expenditure programs. Registration is free of charge.

Problems with CIPP and the limitations for CCTV to accurately test liners have been well-documented.

In 2012, the USEPA published its 'Study Report Evaluation of CIPP In Municipal Gravity Sewers' (EPA 600 R-12 004_R), stating that municipal utilities could only identify deterioration or defects that were easily identified visually and that liner distortions were difficult to identify.

The USEPA also found significant differences testing CIPP liner coupons. In one city a CIPP liner reported a finished thickness of 7.5mm, while the EPA-funded study showed an average measured liner thickness of 5.72mm.

Last year, a paper presented at the 2019 North American Trenchless Technology conference, titled 'Addressing the Shortcomings of a Sampling Strategy in CIPP Quality Assurance Programs' stated "while CIPP technologies have improved, the ability of contractors to obtain more consistent quality installations has not yet been demonstrated."

"The impact of the coronavirus global pandemic has provided an unexpected pause for municipal governments to reassess their capital programs and make sure that necessary 'checks & balances' are in place to deliver the biggest bang-for-the-buck for constituents," states Carissa Boudwin, Vice President, Marketing.

According to co-authors Tony Araujo and Bruce Yao of Paragon Systems Testing (Concord, Ontario, Canada), "100% inspection reveals, that even with a very rigorous quality control regime, a significant percentage of CIPP liners will fail to meet specification requirements."

"We absolutely believe that trenchless rehabilitation and CIPP is an important tool for smart cities to maximize capital investments to deliver resilient and sustainable infrastructure programs," states Mike Condran, PE, Vice President, Electro Scan Inc.

"Unfortunately, legacy pipe inspection technologies have not offered unbiased and repeatable methods to assess full-length 360-degrees of pipelines for leaks," continues Condran.

Recently, a large metropolitan utility contracted with Electro Scan to conduct a detailed assessment of various pipe materials in areas known to have significant infiltration, with little to no defects identified by CCTV.

Not only did the company find significant defects in pre- and post-rehabilitated pipes, but Electro Scan was able to evaluate its recent CIPP liners showing defect patterns that were similar to liner defects at nine (9) other cities using CIPP from the same supplier.

ABOUT ELECTRO SCAN

Headquartered in Sacramento, Calif., the company designs, develops, and markets proprietary pipe condition assessment equipment, delivers field services, and offers cloud-based data processing and reporting applications that automatically locate, measure, and report defects typically not found using legacy inspection methods. In 2020, the company was named to Government Technology’s esteemed GovTech 100 list for the second year in row.

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.