Trenchless Technology Webinar Announced To Review New Standards for Testing & Accepting Cured-In-Place Pipe (CIPP)

Chuck Hansen peers through an exhumed section of CIPP with leaks identified by FELL & confirmed by eye-dropper dye testing, but missed by CCTV. New standards & utility best practices for testing Cured-In-Place Pipe will be discussed in the company's upcoming webinar.

Electro Scan Inc. provides municipal and investor-owned utilities a new level of governance and stewardship over their water & sewer infrastructure.

Use of Cured-In-Place Pipe (CIPP) for trenchless rehabilitation resulted in increase demand for early warning QA/QC of leaks, pinholes, and liner permeability.

New Standards Help Utilities Locate & Measure Leaks in Pre- and Post-Rehabilitation Projects Typically Approved By Less Accurate CCTV Camera Inspection

Registration to attend this FREE webinar is now open.

As a pipe rehabilitation technique invented in the early 1970s, most CIPP projects typically rely on guidelines contained in ASTM 1216, where acceptance of CIPP is based on Closed Circuit Television (CCTV) visual inspection only.

Today, nearly 50% of pipe repairs use CIPP as the preferred approach for trenchless rehabilitation to renew underground sewer & water pipes. Yet, the inability of CCTV to determine watertightness of newly installed CIPP and inability to determine if customer service restorations are watertight, have resulted in widely variable CIPP quality delivered to pipeline owners.

Where correctly installed CIPP lining may eliminate most leaks at joints and cracks, post-rehabilitation defect flows can often exceed pre-rehabilitation levels due to poor or uneven curing, contractor damage, and poor quality customer lateral reconnections.

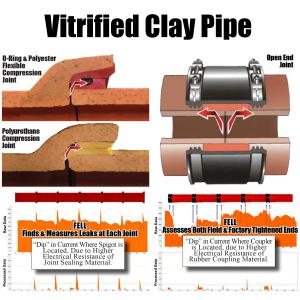

Electro Scan's Trenchless Technology Webinar will discuss how utilities are adopting ASTM F2550 and machine-intelligent Focused Electrode Leak Location (FELL) technology to automatically locate & measure defects from pinholes to major leaks, and verify watertightness of customer service connections, before and after CIPP installation and curing.

Key learning objectives of the Trenchless Technology Webinar, include:

• How FELL technology works, and why it is reliable and repeatable.

• How Agencies are maximizing rehabilitation budgets by setting targeted priorities.

• Advantages of measuring rehabilitation effectiveness the same day, without waiting for a wet-weather event.

• Lessons Learned from informative Case Studies around the country.

In 2019, Electro Scan's Annual CIPP FELL Testing Report evaluated over 110,000 linear feet of CIPP, an increase of 15% from 2018, locating over 14,450 individual defects ranging from pinholes to large defects as defined by ASTM F2550.

Reaction from pipeline owners has been positive, while suppliers have been reluctant to change from less demanding pipe rehabilitation approval using CCTV visual inspection.

Several factors are driving the adoption of using the FELL standard for pre- and post-rehabilitation condition assessments.

First, many senior utility officials wish to position their utility for the future and to leave a significant legacy. Secondly, few academics or industry thought-leaders trusted results from CCTV, especially when projects were 'inspected' by the same contractors responsible for making repairs. Thirdly, small & large, domestic & international, and urban & rural utilities are now fully adopting FELL to show proper stewardship of underground assets and fast-track the reporting of rehabilitation effectiveness.

Additionally, rising sea levels in coastal communities and more severe weather events away from the coast due to climate change have shown engineers that conventional assessment and rehabilitation cycles have been less effective than anticipated.

Peer-reviewed standards published by ASTM (F2550), AWWA (M77), and JASCOMA (No. 12), in addition to benchmark testing by the USEPA, IKT, and numerous municipal utilities, have provided new guidelines and best practices for condition assessment. Especially to accurately test trenchless rehabilitation materials, such as CIPP, Spray-In-Place Pipes, and Spiral Wrap lining methods.

The new standards can also be used to assess common gravity & pressurized pipe materials, including Asbestos Cement, Brick, Cement-Mortar Lined Ductile Iron, Plastic, Reinforced Concrete, and Vitrified Clay Pipe, to establish baseline defect flow levels.

Electro Scan's Trenchless Technology Webinar is scheduled for Wednesday, March 11, 2020, at 1:00 PM US Eastern, 10:00 AM US Pacific, 6:00 PM London (GMT), and Sydney, Australia 5:00 AM (GMT+11).

Guest Webinar Speaker & Case Study

• Rich Cummings, Operations Manager, Hillsborough County, Florida, USA

Additional Webinar Participants and. Case Studies

• Chuck Hansen, Hansen Analytics, LLC, Founder & CEO

• Michael Condran, PE, Electro Scan Inc. Vice President, Southeast

• Carissa Boudwin, Vice President, Marketing

Locating and reducing leaks in our infrastructure is a common challenge facing wastewater collection and water distribution systems, yet effective identification of has been challenging using legacy Acoustic Sensors, CCTV, Ground Penetrating Radar, Laser, Sonar, Smoke Testing, Dye Flood Testing, and Pressure Test results.

Too often agencies only learn that flow reduction goals were missed after having to wait for multi-year flow monitoring comparisons.

Ineffective prioritization, poor contractor performance, and inability to reliably certify repairs as watertight, especially after service restoration, are key factors responsible for ineffective rehabilitation outcomes.

Today, agencies are adopting machine-intelligent FELL, in accordance with ASTM F2550, to identify I/I and test rehabilitation as watertight.

Independent machine-generated results are replacing legacy ambiguous & subjective testing to (1) prioritize pipes with the highest infiltration, (2) test the watertightness of repairs & that rehabilitation meets contract requirements, and (3) compare before and after leakage results to get ‘same day’ estimated percent reductions in flow.

The need for enhanced quality assurance testing of CIPP was first published by Ken Kerri, PhD, PE, in 2015 as part of the 7th Edition, Volume 1, Operations & Maintenance of Wastewater Collection Systems, ISBN 978-1-59371-066-8, referenced by the US EPA to evaluate Capacity, Operation, and Maintenance (CMOM) program activities.

In the past, utilities and consulting engineers would display CCTV inspection results, combining Asset Management & Geographic Information Systems to help prioritize capital expenditure plans; however, missed visual defects often resulted in under-reporting of defects that can contribute to misguided condition assessments.

Combined with the inability to 'visually' assess the watertightness of repairs, replacements, and relining projects, FELL represents a new level of field accuracy and decision support.

Recently, Hansen Analytics LLC benchmarked CCTV and FELL inspections for 33,000 linear feet of pipe, assessing 429 customer service laterals where homes are connected to the agency's sewer main. In this benchmark, a certified CCTV operator identified five (5) defective customer tap locations, while Electro Scan's FELL technology identified 324, or 75%, of service connections with quantified leaks.

Last week, Electro Scan Inc. announced its global partnership with Innovyze Inc. to provide an end-to-end condition assessment & rehabilitation QA/QC solution.

Early adopters of FELL pipe testing are now able to re-test earlier surveyed CIPP liners to re-confirm leak locations and measure changes in leak severity. By measuring how leaks in CIPP get larger over time, surveyed at 1-to-3 year intervals, utilities can compute Remaining Useful Life (RUL) designations, by Supplier, Curing method, and Contractor, which is useful for capital planning and replacement and repair programs.

Electro Scan's webinar announcement coincides with the opening of the Water & Wastewater Equipment, Treatment & Transport (WWETT) conference in Indianapolis, Indiana, the industry's preeminent trade show attended by 14,000 attendees and 600 Exhibitors from 50 countries.

"Legacy CCTV inspection is still appropriate to locate service laterals and obstructions, including construction debris, fats, oil, & grease, crossbores, and roots. However, its inability to locate or quantify leaks, especially in new or relined pipes, indicates that machine-intelligent FELL technology from Electro Scan is best suited to assess pipe conditions and rehabilitation effectiveness," stated Chuck Hansen, Founder & CEO, Hansen Analytics, and investor in Electro Scan Inc.

A leading subject matter expert on pipe condition assessment and former Chair, ASTM Subcommittee F36.20 Committee on Inspection and Renewal of Water and Wastewater Infrastructure, Hansen developed the nation’s first widely used CCTV coding system adopted by nearly 1,000 agencies. In 1989, the City of Houston used Hansen’s CCTV codes and companion software to inspect all 5,000 miles of sanitary sewer with data collected by 250 CCTV trucks. At the time his company was sold in 2007, Hansen customers were storing over 1 million CCTV reports that included nearly 7 million defects.

ABOUT ELECTRO SCAN

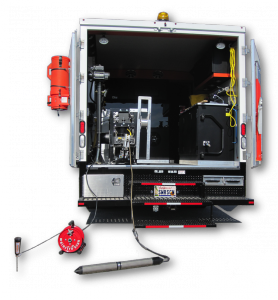

Electro Scan Inc., a leading supplier of machine-intelligent pipeline assessment products and services for the water & wastewater pipeline market. In 2020, the company was named to Government Technology’s esteemed GovTech 100 list for the second year in row. Electro Scan Inc. develops proprietary pipe condition assessment equipment, delivers field services, and offers cloud-based data processing and reporting applications that automatically locate, measure, and report defects typically not found using legacy inspection methods.

ABOUT HANSEN ANALYTICS

Hansen Analytics, LLC, is a leading public sector artificial intelligence (AI) data analytics and data mining company dedicated to supporting asset stewardship and governance of capital assets. The company designs, develops, and supports real-time management dashboards to manage the program management of capital plans.

HASHTAGS

#cctv #cipp #cmom #electroscan #epa #f1216 #f2550

#fell #leakdetection #leaks #m77 #sewer #sewerbackups

#sipp #srp #sso #trenchless #water #wrc #wsaa

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.