Chuck Hansen to Speak at 15th Pipeline Technology Conference in Berlin on Watertightness Testing of Cured-In-Place Pipe

Machine-Intelligent Technology Digitally Delivers New Level of Infrastructure Governance & Stewardship to Ensure Water Asset Resiliency

PTC is Europe’s leading conference on pipeline systems with more than 900 delegates expected to participate. Hansen will present his paper Wednesday, April 1, 2020, titled "Use of Low Voltage Conductivity to Conduct a 10km Inspection of Legacy Cured-In-Place Pipe (CIPP) for a Leak Assessment Project."

A leading subject matter expert on pipeline condition assessment, Hansen is former Chair of ASTM Subcommittee F36.20 Inspection and Renewal of Water and Wastewater Infrastructure. Hansen also developed the first widely-used Closed-Circuit Television (CCTV) coding system for sewer condition assessments in the U.S., used by nearly 1,000 agencies worldwide.

Prior to founding Electro Scan Inc., Hansen was CEO & Founder of Hansen Information Technologies Inc., a leading provider of sewer & water asset management and condition assessment solutions. Founded in 1983, Hansen sold the company to Infor Global in 2007 for US$100 million.

Now, an impact investor supporting measurable environmental and clean tech investments, Hansen is also an investment adviser to a leading California-based venture capital firm.

"Utilities are facing a trillion-dollar price tag to fix and upgrade critical sewer & water infrastructure, but a majority of engineers and contractors typically perform construction reviews using inherently limited visual inspection techniques to 'test' and 'accept' projects," stated Hansen.

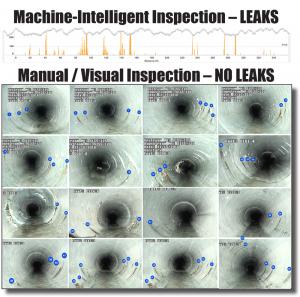

Academics, engineers, and industry consultants have long recognized the limitation of using CCTV cameras to inspect the condition of existing, recently rehabilitated, and newly installed pipelines.

Today, sophisticated robotic cameras are still unable to tell the difference between superficial cracks and cracks that go through a pipe wall. And, Artificial Intelligence (AI) and Machine-Learning (ML) add little to finding leaks that can't be seen due to drawbacks of visual inspection.

Given the impact of climate change and associated rising sea levels, utility managers must address the consequences related to more frequent and severe flooding, sewer overflows, and sewer back-ups due to leaking infrastructure.

Salt water infiltration now causes billions of dollars in damage to water pipeline infrastructure and costly delays in deploying badly needed wastewater reuse programs, as well as significantly impacting treatment plant performance and operational burdens in key coastal areas.

As the gap widens between 'what' utilities expect from their CAPEX investments and 'how' the market delivers CAPEX projects, the industry is calling for unbiased, unambiguous, accurate, and repeatable pipe leakage reporting to ensure resilient and sustainable improvements to infrastructure.

Technologies, like those offered by Electro Scan, play a key role in the digitization of water sector assets, connecting homes & businesses to sources of clean drinking water and the effective collection, treatment, and reuse of wastewater effluent.

Electro Scan's Focused Electrode Leak Location (FELL) technology represents a machine-intelligent, non-destructive, pipe assessment technology that uses a low-voltage, high-frequency electric current to precisely locate leaks, within 3/8th of an inch (1cm), and quantifies defect severity in gallons per minute or liters per second.

While sonar technology has been used to map underwater debris and lasers have been used to measure pipe ovality, sometimes marketed together as a 'multi-sensor' solution, neither technology has been effective in finding or quantifying leak locations or severities.

Similar to holiday testing of protective coatings, FELL is unique in its ability to test a wide variety of full length 360-degree pipe materials, whether empty or fully surcharged.

Data is transmitted to its proprietary SaaS cloud application via Amazon Web Services (AWS) with leak locations and severity data available within minutes.

Hansen has observed that many utilities and engineers are stuck in a 'subjectivity trap' using legacy inspection techniques that overly rely on biased and inherently limited technologies that visually 'see' or acoustically 'hear' leaks.

By using techniques that don't provide a complete assessment of pipes being tested, repair and rehabilitation plans may incorrectly rank and prioritize capital, resulting in ineffective use of capital resources.

Once repairs or renewals are completed, the use of the same techniques to test & accept construction and installations may result in utilities accepting pipelines with major leaks.

"Oftentimes, CIPP materials will line over bad joints and cracks," commented Hansen. "If customer connections are not properly reinstated, larger defects than were not present before rehabilitation may occur; transferring the same amount of water leakage to different locations, without lowering flow rates. With larger defects at laterals that didn't exist before, larger sources of infiltration or exfiltration can easily happen."

"Customer connections that don't leak before rehabilitation, shouldn't leak after rehabilitation," stated Hansen. "If CCTV inspection is used, reliability of rehabilitation projects can't be assured."

Electro Scan's technology was first introduced in 2006, operating in accordance as ASTM F2550, 'Standard Practice for Locating Leaks in Sewer Pipes By Measuring the Variation of Electric Current Flow Through the Pipe Wall.'

Later, ASTM Standard F2550 was reaccredited in 2013 and again in 2018.

In 2017, the company's technology was awarded Certificate No. 12 for 'Water Tightness Investigation Technology' by the Japan Sewer Collection System Maintenance Association (JASCOMA).

Later that year, Electro Scan in partnership with WRc plc, supplied leak detection testing services for a government-sponsors CIPP assessment project undertaken by the world's leading authority in pipe rehabilitation, Institut für Unterirdische Infrastruktur gGmbH (IKT), Gelsenkirchen, Germany.

As a result of its work with IKT, Electro Scan expanded its software to calculate individual quantities for pinhole leaks found in CIPP liners, now a standard feature of its SaaS-based Critical Sewers® cloud application.

In 2019, the company's technology was featured in AWWA's Manual of Water Supply Practices M77, 'Condition Assessment of Water Mains,' where it is the only recommended technology to assess CIPP pipes, in addition to other pipe materials.

International water utilities are now adopting FELL technology for testing & acceptance of trenchless rehabilitation, including CIPP, Spray-In-Place Pipe (SIPP), Spiral Wound Pipe, composite materials, and grout materials.

Test results were recently presented by BKP Berolina Polyester GmbH & Co. KG as part of their Conference Paper at the 37th International No-Dig in Florence, Italy, describing how the company's FELL technology successfully assessed the company's UV-cured CIPP. Minor defects were repaired with the client eliminating 100% of tidal infiltration.

Electro Scan company executives will be attending this year's IFAT Exposition in Messe München, Hall C3, Booth 429, May 4–8, 2020.

Leading sewer & water utilities, consulting engineers, and business partners attending IFAT can meet Michael Condran, P.E., Vice President, Electro Scan Inc., Mike App, Vice President, Electro Scan Inc., and Brad Weston, Director, Electro Scan (UK) Limited.

Held every two years, IFAT 2020 is expected to attract 150,000 attendees from 162 countries and regions. In addition to featuring its suite of machine-intelligent probes for pipe diameters ranging from 3-inch to 60-inch (176mm to 1500mm), Electro Scan staff will also be showcasing its integration with Innovyze® InfoAsset Planner® for risk modeling and rehabilitation decision support.

Hansen will also speak at the Innovyze UK and European Conference in Birmingham, England, March 4, 2020.

Legacy CCTV inspection is still useful, but not for rehabilitation selection or certifying repairs as watertight. In addition to identifying service laterals locations, CCTV is a good solution to observe obstructions, including construction debris, fats, oil, grease, and roots, and to manage ongoing cleaning activities.

CCTV's inability to locate or quantify leaks, especially in existing, newly installed, or relined pipes, especially at service lateral or junction connections, indicates that machine-intelligent FELL technology from Electro Scan is better suited to assess pipe conditions and rehabilitation effectiveness.

ABOUT ELECTRO SCAN INC.

Electro Scan Inc., a leading supplier of machine-intelligent pipeline assessment products and services for the water & wastewater pipeline market, named to Government Technology’s esteemed 2020 GovTech 100 list for the second year in a row. The company develops proprietary pipe condition assessment equipment, delivers field services, and offers a SaaS-based cloud platform for data analytics, online executive dashboards, and reporting applications. The company is also a key supplier to the global Water Infrastructure and Repair Technology (WIRT) market.

HASHTAGS

#ai #astmf2550 #awwam77 #capex #cctv #cipp #cleantech #cleantech #esg #fell #ifat #govtech100 #ikt #impactinvesting #innovzye #leakdetection #m77 #mi #ml #sewer #sipp #srp #sso #sustainability. #trenchless #water #wirt

Carissa Boudwin

Electro Scan Inc.

+1 916-779-0660

email us here

Visit us on social media:

Facebook

Twitter

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.