Cleaner Air Now: Diesel Marine and Rail Repowers Deliver the Greatest, Fastest Air Quality Improvements for the Lowest Cost

Case studies from the Port of Tacoma and the Puget Sound demonstrate the real-world impacts of the latest diesel engines in these largest applications

SACRAMENTO, Calif., Oct. 18, 2018 (GLOBE NEWSWIRE) -- The new generation of advanced diesel technology offers significant emissions reductions and greenhouse gas benefits, and is key to meeting West Coast states clean air and climate objectives. Large engine upgrades to the newest generation diesel technologies deliver the most cost-effective emission reductions when compared to other approaches, and have the biggest positive impact on local communities.

These are sentiments shared today by Ezra Finkin, the Diesel Technology Forum’s Director of Policy and External Affairs, as he addressed air quality managers, fleet operators, researchers and scientists from across the nation at the West Coast Collaborative Partners Meeting. Finkin spoke alongside representatives from the California Air Resources Board, Volvo Construction Equipment, DANNAR and Caterpillar about the best strategies to deliver emissions reductions in non-road applications.

“Diesel engines are the technology of choice and the prime mover for waterborne and rail commerce in the U.S. and around the world,” said Finkin. “Upgrading to the newest diesel technologies offer port and rail operators and the communities they are located in a fast, cost-effective path to cleaner air. The return investment on a dollar-per-ton of emissions reduced makes these projects a compelling choice that cannot be ignored.”

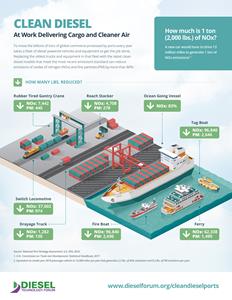

Starting in 2015, new diesel engines used in marine applications and switcher locomotives in the United States achieve dramatic emissions reductions in nitrogen oxides (NOx) and fine particle emissions on the order of 88 and 95 percent compared to older models. These fourth-generation advanced diesels – “Tier 4” engines – are available and being deployed today to reduce emissions. By various estimates, upgrading the largest of these engines could save as much as 30 tons of NOx and 2,000 pounds of fine particle emissions per year. The opportunity for transitioning to new generation of technology in the marine and locomotive fleet is substantial as the U.S. Environmental Protection Agency estimates that, by 2020, only 5 percent of the switch locomotive and 3 percent of the marine workboat fleets will have transitioned to the latest generation of near-zero emission diesel technologies.

“Case studies from the Port of Tacoma and the Puget Sound demonstrate the real-world impacts of the latest diesel engines in these largest applications,” said Finkin. “Upgrading the engine of one switcher locomotive in the Port of Tacoma reduced 34 tons of NOx emissions and almost 2,000 pounds of fine particles from the Port of Tacoma, and saved the rail operator 19,000 gallons of fuel. In the Puget Sound, upgrading three engines on one workboat saves more than 1,000 tons of greenhouse gas emissions every year, as well as eliminates 3.2 tons of NOx and 400 pounds of fine particles, and saves the operator 45,000 gallons of fuel.”

Joint research conducted by the Diesel Technology Forum and the Environmental Defense Fund (EDF) documents the significant emission reduction benefits that can be gained by replacing older engines in tug boats and switcher locomotives with the latest clean diesel models. According to the study, clean diesel technology upgrades for large tug and switcher locomotive engines cost only $4,379 to $15,201 per ton of NOx, compared to more than $30,000 per ton of NOx for many other emission reduction projects.

“Port and rail operators should ask this question: Is it better to invest in one new alternative power demonstration unit that is a so called ‘zero emission’ option at a great cost, while leaving 10 other older and higher-emitting engines in operation,” said Finkin. “The smarter choice is to use those same funds to upgrade all 11 engines to the newest near-zero emissions diesel technology, thus allowing more communities near ports and rail yards to reap the benefits of the substantial reductions possible with clean diesel upgrades?”

Case Study: 34 tons of NOx Reduced for Tacoma Residents

- With $2 million coming to the State of Washington through a federal Diesel Emission Reduction Act (DERA) grant from the U.S. Environmental Protection Agency (EPA), the Washington Department of Ecology and the Port of Tacoma had to decide how to most effectively spend the funds.

- After careful evaluation, it was decided the funds should go to improve the air quality in the Port of Tacoma’s railyard. The project selected was to upgrade the engine of a switcher locomotive so as to meet the latest Tier 3 standards.

- The particular engine selected for upgrading had been in continuous use at the Port of Tacoma since the 1950s, manufactured prior to the current generation of modern engine emissions control technologies.

- Upgrading this single switcher locomotive to a new, Tier 3 diesel engine immediately removed 34 tons of NOx emissions, eliminated almost 2,000 pounds of fine particles, and saved the rail operator 19,000 gallons of fuel.

Case Study: 3.2 tons of NOx Reduced in the Puget Sound

- The Puget Sound Clean Air Agency and the U.S. Maritime Administration determined that the “Island Chief” workboat required an update to continue operating.

- This tugboat was operating with two unregulated propulsion engines and one unregulated auxiliary engine. These engines were considered “unregulated” due to their age; they were manufactured before the present emissions control requirements were put into effect.

- For $225,000, these old engines were replaced with new diesel technologies – two Tier 3 propulsion engines and one Tier 4 auxiliary engine.

- Adding new diesel engines on this one workboat eliminates 3.2 tons of NOx and 400 pounds of fine particles, and saves the operator 45,000 gallons of fuel – which consequently saves 1,000 tons in greenhouse gas emissions – every year.

Learn more:

https://www.dieselforum.org/largeengineupgrades

https://www.dieselforum.org/about-clean-diesel/port-and-marine

https://www.dieselforum.org/about-clean-diesel/rail

# # #

About The Diesel Technology Forum

The Diesel Technology Forum is a non-profit organization dedicated to raising awareness about the importance of Diesel engines, fuel and technology. Forum members are leaders in clean Diesel technology and represent the three key elements of the modern clean Diesel system: advanced engines, vehicles and equipment, cleaner Diesel fuel and emissions-control systems. For more information, visit http://www.dieselforum.org.

Attachment

Sarah Dirndorfer Diesel Technology Forum 301-668-7230 sdirndorfer@dieselforum.org

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.