Automated Material Handling Equipment Market to Hit USD 152 Billion by 2035, Driven by Warehouse Automation and Robotics

Automated Material Handling Equipment Market to reach USD 152 Billion by 2035 at 7.0% CAGR, fueled by robotics, e-commerce, and global logistics automation.

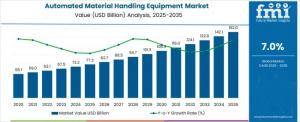

NEWARK, DE, UNITED STATES, November 10, 2025 /EINPresswire.com/ -- The Automated Material Handling Equipment Market is entering a transformative decade. Estimated at USD 77.3 billion in 2025, the market is projected to reach USD 152.0 billion by 2035, expanding at a 7.0% CAGR, according to the latest industry analysis. This growth trajectory reflects the rapid digitization of supply chains, accelerated e-commerce adoption, and rising investments in smart factories and automated warehouses worldwide.

From USD 55.1 billion in 2020 to USD 72.2 billion in 2025, the first phase of expansion is being fueled by the surge in automated guided vehicles (AGVs), conveyor systems, and sortation technologies designed to optimize warehouse efficiency and reduce manual dependency. Between 2026 and 2030, the market is forecast to advance to USD 101.3 billion, supported by the integration of robotics, predictive analytics, and industrial IoT in logistics operations. By 2035, automation and AI-enabled intralogistics systems will push the market to USD 152.0 billion, cementing AMHE’s role at the core of next-generation industrial ecosystems.

Automation Defines the New Era of Supply Chain Efficiency

The global AMHE market’s momentum is being powered by the growing demand for accuracy, speed, and flexibility in distribution and manufacturing. As warehouse footprints expand and labor costs climb, companies are increasingly deploying AI-based vision systems, robotics, and IoT sensors to streamline material movement, improve order fulfillment accuracy, and lower operational expenses.

“Automation has evolved from being a productivity enhancer to a strategic imperative,” said a senior industry analyst. “From global retailers to 3PL providers, automated handling systems are now the backbone of efficient logistics and competitive manufacturing.”

E-commerce growth and omnichannel retailing have also accelerated this shift. High-volume order management, same-day delivery expectations, and seasonal surges have led to the widespread adoption of conveyors, automated storage and retrieval systems (ASRS), and mobile robotics for faster and more accurate throughput.

Key Market Statistics

- Market Value (2025): USD 77.3 Billion

- Forecast Value (2035): USD 152.0 Billion

- Forecast CAGR (2025–2035): 7.0%

- Leading Product Segment (2025): Automated Guided Vehicles (AGV) – 38.1% Share

- Top Growth Regions: North America, Asia-Pacific, Europe

Segmental Insights

Automated Guided Vehicles (AGV) Lead the Product Segment

The AGV segment, accounting for 38.1% of the total market share in 2025, represents the largest and fastest-growing category. Modern AGVs are equipped with advanced sensors, real-time data synchronization, and flexible navigation systems, enabling seamless material transport in high-density warehouses. Their adaptability to changing workflows without infrastructure modification has made them indispensable across logistics and manufacturing facilities.

3PL Remains the Largest Application Area

Third-party logistics (3PL) providers are set to hold 44.3% of the market share by 2025. Automation within 3PL environments supports the management of dynamic inventories, high order volumes, and real-time delivery tracking. The integration of autonomous mobile robots (AMRs) and intelligent storage systems has allowed logistics operators to maintain scalability and meet evolving client expectations across sectors such as retail, automotive, and pharmaceuticals.

Manufacturers Drive End-Use Adoption

The manufacturing sector, contributing 39.5% of the market in 2025, is leveraging automated handling systems to support just-in-time delivery, reduce human error, and ensure continuous production flows. Industries such as automotive, electronics, and consumer goods are adopting connected handling systems integrated with ERP and digital twin technologies to enhance production visibility and resilience.

Regional Outlook — Asia-Pacific Leads Global Expansion

The AMHE market’s regional dynamics highlight Asia-Pacific as the most dynamic hub, driven by industrial modernization and e-commerce growth.

- China is projected to record a 9.5% CAGR (2025–2035), supported by smart logistics investments, component localization, and large-scale adoption of ASRS and shuttle-based systems.

- India follows with 8.8% CAGR, driven by rapid warehouse automation, 3PL expansions, and government-backed industrial corridors.

- Europe continues strong, with France (7.4%) and the United Kingdom (6.7%) emphasizing automation in grocery and retail logistics.

- The United States posts steady 6.0% CAGR, with modernization focused on brownfield retrofits, predictive maintenance, and high-speed case handling in cold chain networks.

Explore the full market insights and future trends—read the complete Market Report today! https://www.futuremarketinsights.com/reports/sample/rep-gb-24264

Buy Now Report Here: https://www.futuremarketinsights.com/checkout/24264

Competitive Landscape — Innovation at the Core

The global AMHE market is marked by intense competition among leading players such as Toyota Industries Corporation, Honeywell International Inc., KION SSI SCHAEFER Group, Jungheinrich AG, KUKA AG, Murata Machinery Ltd., Hanwha Corporation, Hyster-Yale Materials Handling, TGW Logistics, KNAPP, and Viastore.

These companies are investing in robotics-driven automation, AI-based warehouse management software, and energy-efficient modular systems to enhance scalability and reduce commissioning timelines. Strategic partnerships between automation providers and logistics operators are redefining how intralogistics ecosystems function—turning automation into a service model.

Future Outlook

As global supply chains become increasingly digital and demand patterns evolve, automated material handling equipment will serve as a strategic enabler of operational agility. By 2035, the convergence of AI, robotics, IoT, and predictive analytics will redefine warehouse operations, making intelligent automation the cornerstone of resilient and cost-efficient logistics.

In summary, the Automated Material Handling Equipment Market is poised for sustained double-digit expansion across emerging and developed economies. With growing investments in smart logistics and automation-led manufacturing, the next decade will mark the rise of a fully integrated, data-driven supply chain landscape.

Related Reports:

Industrial Robotic Motors Market- https://www.futuremarketinsights.com/reports/industrial-robotic-motors-market

Condition Monitoring Service Market- https://www.futuremarketinsights.com/reports/condition-monitoring-service-market

Domestic Booster Pumps Market- https://www.futuremarketinsights.com/reports/domestic-booster-pumps-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.