Sparking curiosity in the future semiconductor workforce

The United States semiconductor industry is projected to have between 60,000 and 100,000 unfilled jobs by 2030. As the need for semiconductor technicians, engineers and scientists continues to increase, there is also a growing demand for innovative ways to train this anticipated workforce. But such training typically requires expensive clean rooms and advanced equipment, resources that many schools don't have access to.

A team of researchers, which included high school and community college students, found a solution to this challenge by using artificial intelligence-powered virtual reality (VR) to create simulations as a cost-effective alternative for people to learn about the process of semiconductor fabrication. The results of their research, which is supported by the U.S. National Science Foundation Advanced Technological Education Micro Nano Technology Education Center at Pasadena City College (PCC), in collaboration with the University of California, Irvine (UCI), are available in the Journal of Advanced Technological Education.

"Many students, especially those at underfunded schools, never get to see or touch the real semiconductor fabrication tools," said Kristal Hong, a member of the research team and a computer science major at UCI. "I, myself, was a community college student without access to a cleanroom, so I know how that gap can dampen student enthusiasm."

By using AI-powered VR to create cleanroom simulations, the team is offering a learning channel outside of traditional classrooms and labs for students who don't have in-person access to semiconductor fabrications and for others who might never have considered the semiconductor field. This flexibility is crucial to growing the much-needed semiconductor workforce, Hong said. "If a student learns best by doing, VR can bridge the gap to help them grow and succeed, even when physical resources are scarce."

Credit: Kristal Hong

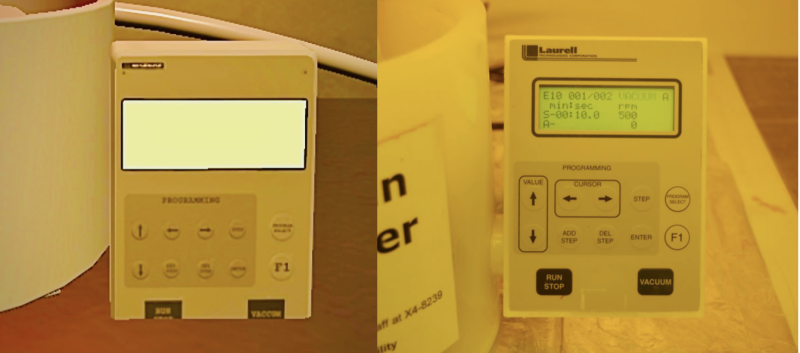

To create the virtual simulations, the researchers regularly toured the UCI Integrated Nanosystems Research Facility, taking pictures and videos, interacting with equipment, and learning from educators, including Guann Pyng "G.P." Li, electrical engineering and computer science professor at UCI.

From this experience, the team manually generated a digital twin of the UCI cleanroom — a virtual representation of the real-world environment — by translating the semiconductor manufacturing process from the in-person lab into a simulation using VR, which has a similar feel to a video game. They then guided users step-by-step through the virtual semiconductor fabrication process. From there, the 29 study participants evaluated the simulation's effectiveness.

Credit: Ishan Jha

"This was a peer-to-peer learning experience, where the researchers created and consumed the content with the goal of making engaging simulations for their peers," Li said. "With these virtual experiences, more learners will have a chance to understand how the semiconductor process takes place."

Importantly, the researchers used the off-the-shelf GPT 4 application from OpenAI – a large language model used for natural language processing – to personalize the VR learning experience and increase the effectiveness of the virtual semiconductor training.

"If someone has a question, they can ask the AI and get an instant answer, just as if an instructor were standing beside them," Hong said. "We plan to continue studying AI use in the lab and in VR to refine and improve the training experience over time."

By using AI-powered VR, the team not only removed the physical and financial barriers to accessing semiconductor equipment, but they also found that this method provided an engaging format that kept students motivated and interested in the semiconductor field.

"Their excitement was palpable," said Hong. "Study participants cheered when a process worked, and they would collaborate to troubleshoot virtual errors. It was eye‐opening to watch how quickly VR could transform a student's perception of an otherwise abstract topic into something tangible and engaging."

Credit: Ishan Jha

By taking a fabrication environment and transporting it into a virtual environment, "it becomes much more accessible to younger students who have already been exposed to videogame-like scenarios," said Ishan Jha, a high school student and member of the research team. "Participating in this research gives us [high schoolers] a taste of what's happening in these industries [AI/VR and semiconductors], because a lot of us plan to attend college, and we want that prior exposure that will prepare us for success later on."

The team sees the potential for scaling this cost-effective experience to more learners across the country. Mercer County Community College (MCCC) approached the PCC/UCI team with interest in creating similar AI-powered VR simulations. MCCC is now working with Princeton University to facilitate this effort.

Looking ahead, the team plans to replicate the project at additional institutions, expand partnerships to other universities and gather data from new participants with the goal to better understand if early VR exposure makes learners more likely to pursue semiconductor‐related internships or jobs, and how prepared they feel compared to peers without VR experience. And as AI capabilities continue to evolve, the team is considering additional ways to use generative AI to assist with their VR training simulations.

While observing the researchers in his lab, Li said it gave him great hope for the future of the AI and semiconductor workforce. "These students are the future of our nation," Li said. "When they see something that inspires them, they want to really explore it. And even if they have no prior knowledge or experience in a semiconductor manufacturing room or if they have minimal knowledge of AI or VR, when they are engaged, they are motivated, and they can make a difference."

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.