Olaroz Mineral Resource Update, and Stage 1 & 2 Operations Update

BRISBANE, Australia, Sept. 25, 2023 (GLOBE NEWSWIRE) -- Allkem Limited (ASX|TSX: AKE) (“Allkem” or “the Company”) is pleased to announce an update to the Olaroz lithium brine operation located in Jujuy Province in Argentina. Allkem has reviewed and updated the Mineral Resources and economics for the Olaroz Lithium Facility (“Olaroz”) including Stage 1 and Stage 2. In April 2022, Allkem released a Technical Report updating key economic metrics for Olaroz Stage 2 and in March 2023, Allkem released a Technical Report (“previous study”) updating Mineral Resources.

HIGHLIGHTS

Stage 1 and 2 (42,500 lithium carbonate equivalent tonnes per annum)

Financial Metrics

- Pre-tax Net Present Value (“NPV”) of US$7.01 billion at a 10% discount rate and a Post-tax NPV of US$4.56 billion

- Long term operating costs for the combined Stage 1 and Stage 2 operation are estimated at US$4,149 per tonne lithium carbonate equivalent (“LCE”) over the life-of-mine considering operational synergies from the joint operation of Stage 1 and 2

Mineral Resource

- Total Mineral Resource Estimate of 22.63 million tonnes (“Mt”) LCE, a 10% increase from the previous estimate in March 2023 with a 52% increase in Measured Mineral Resources

- The Mineral Resource now comprises 11.54 Mt of LCE, as Measured, and 3.83 Mt as Indicated for a combined 15.38 Mt of Measured & Indicated Mineral Resource. There is an additional 7.25 Mt of Inferred Resources for a total resource of 22.6Mt (Measured, Indicated and Inferred)

- The improvement in Mineral Resource categorisation results from reclassification of Indicated Mineral Resources between 200 and 650 m depth as Measured Mineral Resources in the pumping field area, reflecting the greater amount of information available from pumping performance since installation of the Stage 2 wells and the addition of Maria Victoria tenements

- Olaroz's life of mine (“LOM”) production represents ~8.5% of the Measured and Indicated Mineral Resources, further confirming the Tier 1 status of the basin, and its potential to support additional expansions

Stage 2 (25,000 lithium carbonate equivalent tonnes per annum)

Schedule Update

- The expansion achieved the first wet lithium carbonate production in July 2023. Commissioning activities are ongoing and production is scheduled for H2 CY23, with ramp-up expected to take 1 year

Managing Director and Chief Executive Officer, Martin Perez de Solay commented:

“We have recently concluded a review of the company’s resource base. The improvements in Mineral Resource classification for the project are built on our long-term commitment to understand the hydrology of the Olaroz-Cauchari basin to the best extent possible and to manage extraction from the basin in a responsible manner. This Mineral Resource base will support future studies focusing on maximising the productive capacity of this Tier 1 resource.”

PROJECT BACKGROUND

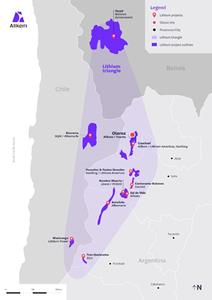

Allkem is the operator and majority owner of Olaroz, located in the Jujuy Province, in northwest Argentina (Figure 1).

Figure 1: Olaroz Project Location

https://www.globenewswire.com/NewsRoom/AttachmentNg/614945e5-ea1f-4d1a-8014-5cf8bd2bb65a

Allkem Limited holds 66.5% of Olaroz through its local subsidiary Sales de Jujuy S.A. (“SDJ”), with the remaining project ownership held by Toyota Tsusho (25%) and the Jujuy Energía y Minería Sociedad del Estado (JEMSE) (8.5%). This Joint Venture holds mineral properties that cover the majority of the Salar de Olaroz, including tenements covering 47,615 hectares and two exploration properties (“cateos”) consisting of 33 mining concessions.

Olaroz is fully permitted by the provincial mining authorities and has provincial and federal permits, to allow operations for an initial 40 year mine life with renewable options to extend beyond 2053. Olaroz Stage 1 is the original project which commenced operation between 2013 and 2015 during the production ramp-up, with a maximum production capacity of 17,500 tpa of lithium carbonate.

The Olaroz Stage 2 expansion, targeting an additional 25,000 tpa of lithium carbonate, produced first wet concentrate in July 2023, and is scheduled to commence production in H2 CY2023. Olaroz Stage 1 and Stage 2’s cumulative site lithium carbonate production capacity is 42,500 tpa.

GEOLOGY & MINERALISATION

The Olaroz salar is located in the elevated Altiplano-Puna plateau of the Central Andes. The Puna plateau of north-western Argentina comprises a series of dominantly NNW to NNE trending reverse fault-bounded ranges up to 5,000-6,000 m high, with intervening internally drained basins at an average elevation of 3,700 m. High evaporation rates, together with reduced precipitation, have led to the deposition of evaporites in many of the Puna basins since 15 Ma, with borate deposition occurring for the past 8 Myr. Precipitation of salts and evaporites has occurred in the centre of basins where evaporation is the only means of water escaping from the hydrological system.

Mineralization in the Olaroz salar consists of lithium dissolved in a hyper-saline brine, which is about eight times more concentrated than seawater. The lithium concentration is the product of the solar evaporation of brackish water which flows into the salar as groundwater and occasional surface water flows. The concentrated brine with lithium is distributed throughout the salar in pore spaces between grains of sediment. The brine also extends a considerable distance away from the salar, beneath alluvial gravel fans around the edges of the salar. These areas are largely unexplored by the company to date. In addition to lithium, there are other elements, such as sodium, magnesium, and boron, which constitute impurities that are removed in the ponds and processing plant.

MINERAL RESOURCE UPDATE

Olaroz wellfield update

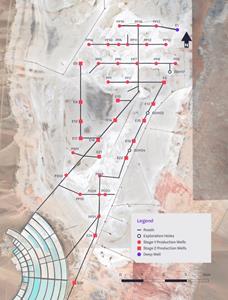

Following installation of the Stage 1 production wellfield at Olaroz, several deeper wells were installed in 2014 below 200 m in depth and subsequently utilised for Stage 1 production. This deeper drilling intersected high porosity and permeability sand units, with flow rates of over 30 litres per second (l/s). This discovery initiated evaluation of the deeper resource potential of the basin.

Since 2011, material amounts of new information have been obtained from exploration and production activities at Olaroz. This included geological and production data from Stage 1 production and monitoring holes generally drilled to 200m, with some to 350m and 450 m; and the Stage 2 expansion production and monitoring holes to depths of between 450 and 650 metres. Additional information has also come from drilling in Cauchari, a 1,408 m deep exploration hole north of the production holes in Olaroz and geophysical surveys over the whole basin.

Olaroz Stage 2 involved an expansion of facilities and production capacity to reach a total production capacity of 42,500 tpa LCE. This involved the installation of additional wells for brine extraction and for industrial water extraction, pipelines for brine and fresh water, additional brine collection ponds, lime plants, significantly expanded evaporation ponds (adjacent to the existing ponds), a new plant facility, stores, power generation facilities, reverse osmosis plant, production plant and accommodation camp.

The last of the 15 new wells for Stage 2 production (Figures 2 and 4) was completed late in 2022. These production wells are now installed to depths between 450 m and 650 m (with one hole to 751 m), and most of the brine production comes from these deeper levels in the Salar on a 1 km grid spacing in the central to eastern area of the Salar, between the original Northern and Southern wellfields. In addition to the production wells, a number of diamond drill holes provide core and brine samples and allowed the installation of monitoring wells. The Stage 2 production wells are producing a combined flow of approximately 396 l/s, at an average per well of 28 l/s, since beginning operation. This is considerably higher than the Stage 1 wells, which have averaged 11 l/s per hole since the beginning of 2017.

Samples from the wells were sent to external and internal laboratories for chemical analysis. This information and downhole geophysics (from a borehole magnetic resonance tool, part of a broader suite of geophysical tools) were used to update the geological model.

The newly completed wells reached depths between 390 m and 751 m (E15). The lithium concentrations recorded an average lithium grade of 643 mg/L and varied from 544 mg/L to 789 mg/L. Further drilling information and analytical results are displayed in the Annexures.

Wellfield operation started August 2013 with the ramp-up of stage 1 wells and then in CY21 wellfield production increased again with the ramp-up of stage 2 wells as seen in Figure 2.

Figure 2: Production Wellfield Pumping and Extracted Lithium in Brine to ponds (August 2013 to June 2023)

https://www.globenewswire.com/NewsRoom/AttachmentNg/61bee127-e443-4d18-8d1b-68efc13ac3bd

The historical well production from start of wellfield operation to 30 June 30 2023, is ~291kt of LCE. 286kt thousand tonnes of LCE was depleted from measured resources and 5kt of LCE was depleted from indicated resource over this period.

Brine Mineral Resource Estimate

Hydrominex Geoscience was engaged to estimate the lithium Mineral Resources in brine for various areas within the Salar de Olaroz basin in accordance with the 2012 edition of the JORC code (“JORC 2012”). Although the JORC 2012 standards do not address lithium brines specifically in the guidance documents, the QP has taken into account the Australian Association of Mining and Exploration Companies (AMEC) brine guidelines and the NI 43-101 guidelines for lithium brines set forth by the Canadian Institute of Mining, Metallurgy and Petroleum (CIM 2014). Hydrominex Geoscience considers these complies the intent of the JORC 2012 guidelines with respect to providing reliable and accurate information for the lithium brine deposit in the Salar de Olaroz.

Figure 3: Location map of Measured, Indicated and Inferred Lithium Mineral Resources

https://www.globenewswire.com/NewsRoom/AttachmentNg/271fb3cf-5d48-45a6-82ef-5323ca43e98c

The 2023 Mineral Resource estimate is outlined in the following Table 1 and 1a presenting the lithium and lithium carbonate tonnages. The previous estimate at March 2023 is also presented in Table 2.

A lithium cut-off grade of 300 mg/L was utilized based on a projected LCE price of US$20,000 per tonne over the entirety of the LOM. The total revised Mineral Resource estimate of 22.63 Mt LCE (detailed in Table 1) reflects a 10 % total increase to the prior Mineral Resource of 20.65 Mt LCE (detailed in Table 2).

Table 1: Olaroz Mineral Resource Estimate at August 20231

| Category | Brine volume | Average Li | In Situ Li |

Li2CO3 Equivalent |

Li2CO3 Variance to March 2023 |

| m3 | mg/l | tonnes | Tonnes | % | |

| Measured | 3.3 x 109 | 659 | 2,170,000 | 11,540,000 | 53% |

| Indicated | 1.2 x 109 | 592 | 720,000 | 3,840,000 | -46% |

| Measured & Indicated | 4.5 x 109 | 641 | 2,890,000 | 15,380,000 | 5% |

| Inferred | 2.2 x 109 | 609 | 1,360,000 | 7,250,000 | 21% |

| Total | 6.7 x 109 | 636 | 4,250,000 | 22,630,000 | 10% |

| |||||

Table 1a: Olaroz Mineral Resource Estimate at August 2023 by company

|

Category |

Brine volume |

Average Li |

In Situ Li |

Li2CO3 | Li2CO3 |

| Equivalent | Variance to March 2023 | ||||

| m3 | mg/l | tonnes | Tonnes | % | |

| Measured | 3.3 x 109 | 659 | 2,170,000 | 11,540,000 | 53% |

| SDJ JV (66.5% AKE) | 2.7 x 109 | 664 | 1,796,000 | 9,561,000 | |

| Olaroz Lithium (100% AKE) | 2.0 x 108 | 700 | 142,000 | 756,000 | |

| La Frontera Minerals (100% AKE) | 3.8 x 108 | 595 | 229,000 | 1,219,000 | |

| Indicated | 1.2 x x109 | 592 | 720,000 | 3,840,000 | -46% |

| SDJ JV (66.5% AKE) | 1.1 x 109 | 591 | 659,000 | 3,508,000 | |

| Olaroz Lithium (100% AKE) | 4.2 x 107 | 645 | 27,000 | 144,000 | |

| La Frontera Minerals (100% AKE) | 5.9 x 107 | 573 | 34,000 | 181,000 | |

| Measured & Indicated | 4.5 x 109 | 641 | 2,890,000 | 15,380,000 | 5% |

| SDJ JV (66.5% AKE) | 3.8 x 109 | 645 | 2,455,000 | 13,069,000 | |

| Olaroz Lithium (100% AKE) | 2.4 x 108 | 691 | 169,000 | 900,000 | |

| La Frontera Minerals (100% AKE) | 4.4 x 108 | 592 | 263,000 | 1,400,000 | |

| Inferred | 2.2 x 109 | 609 | 1,360,000 | 7,250,000 | 21% |

| SDJ JV (66.5% AKE) | 1.2 x 109 | 623 | 764,000 | 4,067,000 | |

| Olaroz Lithium (100% AKE) | 2.4 x 108 | 650 | 154,000 | 820,000 | |

| La Frontera Minerals (100% AKE) | 7.3 x 108 | 608 | 443,000 | 2,358,000 | |

| Total | 6.7 x 109 | 636 | 4,250,000 | 22,630,000 | 10% |

| SDJ JV (66.5% AKE) | 5.0 x 109 | 640 | 3,219,000 | 17,136,000 | |

| Olaroz Lithium (100% AKE) | 4.8 x 108 | 671 | 323,000 | 1,720,000 | |

| La Frontera Minerals (100% AKE) | 1.2 x 109 | 602 | 706,000 | 3,758,000 |

Mineral Resource categories were assigned based on available data and confidence in the interpolation and extrapolation possible given reasonable assumptions of both geologic and hydrogeologic conditions.

Table 2: Olaroz Mineral Resource Estimate at March 2023

| Category | Brine volume | Average Li | In Situ Li |

Li2CO3 Equivalent |

| m3 | mg/l | tonnes | tonnes | |

| Measured | 2.2 x 109 | 657 | 1,420,000 | 7,550,000 |

| Indicated | 2.2 x 109 | 612 | 1,340,000 | 7,130,000 |

| Measured & Indicated | 4.4 x 109 | 634 | 2,760,000 | 14,680,000 |

| Inferred | 1.8 x 109 | 606 | 1,120,000 | 5,970,000 |

| Total | 6.2 x 109 | 625 | 3,880,000 | 20,650,000 |

| The reader is cautioned that Mineral Resources are not Ore Reserves and do not have demonstrated economic viability. | ||||

Additional information for the resource estimation can be found in the Annexures.

Olaroz basin geology

Exploration activities, since Allkem acquired the properties in 2008, have consisted of extensive geophysical programs and drilling over the Olaroz basin. Geophysical programs have included AMT (Audio-Magnetotellurics) electrical surveying, and vertical electrical soundings to define the lateral extents of the brine beneath alluvial sediments, around the margins of the salar. This is important in order to constrain the geological and hydrogeological models and assess areas for brine prospectivity off the salar. The northern SDJ and 100% Allkem properties have been subject to minimal exploration to date. However, electrical geophysics indicates prospectivity for brine beneath alluvial and deltaic sediments north of the Olaroz salar in the exploration mining right, Cateo 498, and other properties.

Additional geophysics has included an extensive gravity and magnetic survey across the basin, that provided information on the basin depth and corroborated the early geophysical interpretation which indicated the basin is more than 1 km deep.

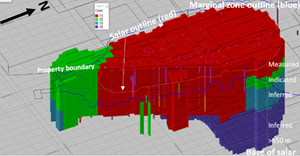

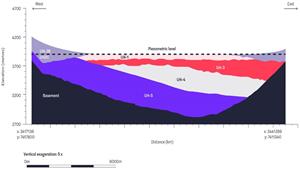

Since the exploration drilling for the 2011 Mineral Resource estimation, conducted between 2008 to 2011, more extensive drilling undertaken for exploration and production well installation has provided information to depths of 751 m in Olaroz (generally 400 to 650 m) and better defined the basin geology. Additionally, one deep exploration hole has been drilled at the north end of the production area to a depth of over 1400 m, without intersecting basement rocks. This drilling led to development of a mixed salar basin model, with five separate geological and hydrogeological (hydrostratigraphic) units above the basement, defined by geological and geophysical logging of holes (refer to Figure 4 and 5).

- UH1 - Upper evaporite deposits, porous halite, clay, sand and silt

- UH2 - Alluvial fans on the western and eastern margins of the Salar, which contain brine beneath brackish water off the Salar (as defined by production well E26)

- UH3 - Mixed sediments with clay and sand intervals

- UH4 - Evaporite deposits, principally halite, with clay, silt and sand interbeds

- UH5 - Sand units, interbedded with clay and silt. Sandy material is sourced from the historical western margin of the basin and becomes progressively deeper in the east of the basin

Drilling has not intersected the basement rocks beneath the Salar and it is possible that additional units will be intersected in future deeper drilling. In the central eastern part of the salar unit UH4 is thicker, reflecting the nucleus of the Salar in this area.

The geological interpretation across Olaroz is also consistent with the independent interpretations on adjacent projects based on drilling conducted by Allkem and Advantage Lithium in Cauchari, and the work conducted by Minera Exar in Cauchari, being the southern continuation of the Olaroz structural basin.

Figure 4: Geological model of the Olaroz salar looking north through the northern part of the basin

https://www.globenewswire.com/NewsRoom/AttachmentNg/cf882adf-f7a5-4663-a8ff-5aa775b5959f

Figure 5 – Olaroz production well locations

https://www.globenewswire.com/NewsRoom/AttachmentNg/d41b90c7-f924-4a8d-94e6-d9a1399a2919

Resource estimate data sources

Average production well brine chemistry values, from throughout pumping of the wells, have been used as inputs for the resource estimation, in addition to the interval samples historically collected in the upper 200 m. This is considered an acceptable approach in this situation, given the level of information available in the Olaroz salar, hydrogeological continuity between drill holes, comparison between historical interval samples and pumped brine concentrations and the history of pumping data available. Additional diamond drilling is recommended for future resource evaluations and to allow installation of additional deep monitoring wells.

Geophysical logging in the deeper holes has confirmed generally consistent drainable porosity and permeability characteristics throughout the clastic sediments with higher porosities and permeabilities associated with more sand dominated intervals.

Mineral resource estimation

Estimation of a brine resource requires definition of:

- The aquifer distribution (in this case restricted to the Salar outline, except around hole E26 in the south)

- The distribution of drainable porosity (specific yield) values

- The distribution of lithium and other elements in the brine defined by drilling

- The external limits (geological or property boundaries) of the resource area

The resource grade is a combination of the aquifer volume, the drainable porosity (portion of the aquifer volume that is filled by brine that can potentially be extracted) and the concentration of lithium in the brine.

The Olaroz aquifer system is not a conventional water supply style aquifer, based on a discrete geological unit, but rather a layered sequence of sediments that contributes brine flow to production wells. More permeable sand and gravel units provide relatively higher flows. The surface outline of the Salar is used to delimit the area of the resource estimate (except for the off-salar extension around E26). The 2023 resource covers 147.9 km2, larger than the original 2011 Resource area (93 km2).

The expanded area reflects inclusion of the Olaroz Lithium and la Frontera (Maria Victoria) properties, which were not part of the original property holdings. The resource has been further expanded by the drilling of hole E26 south of the Salar, allowing definition of resources beneath the alluvial gravels south of the Salar (Figure 5). Brine saturated sediments are known to extend beneath alluvial sediments surrounding the Salar and this was confirmed in drilling of hole E26 on the edge of the gravels beside the Salar, which continued to 510 m in sandy and gravel material.

The resource estimate is limited laterally by the boundaries (Figure 3) with adjacent property owner Exar, in the salar to the east and north of the properties owned by Allkem subsidiaries (Olaroz Lithium and La Frontera Minerals) and SDJ entities. The resource estimate is limited at depth by the sediment-basement contact interpreted from the gravity geophysical survey conducted over the basin. Drilling suggests this interpretation underestimates the basin depth.

Within the Salar the three-dimensional distribution of the different hydrostratigraphic units was defined using Leapfrog 3D software, with these units based on geological and geophysical logging observations. The resource is entirely within the Salar, except in the gravel area extending west from production hole E26. This is the only location where brackish water overlies brine within the resource estimate. Lower lithium concentration blocks have been excluded from the resource by the 300 mg/l cut-off grade. In all other areas within the resource brine begins from within several metres of the salar surface.

The porosity data set consisted of interval porosity samples analysed in an independent laboratory for the upper 200 m and the BMR downhole geophysics from 200 to 650 m. These were used to generate a block model across the salar area, applying ordinary kriging to the composited drainable porosity data.

The distribution of lithium and other elements was estimated from point sampling data from the upper 200 m of the model, where samples are typically spaced every 6 m in the 200 m holes and 3 m or less in the 54 m holes. Below the upper 200 m the resource was estimated based on the pumped samples from the production wells, with a single value per hole representing the average pumped lithium value, assigned to the areas with screens in the production wells.

The block model was constructed with 500 by 500 m blocks, with a 20 m vertical extent (Figure 6 and Figure 7). Only the portion of the block inside the salar outline is reported in the resource (with the exception of the area around E26). The resource estimate was undertaken using Datamine software, with variograms developed for the point samples from the upper 200 m. Estimation was undertaken using ordinary kriging. The ordinary kriging method is the most commonly used kriging method. In areas of sparse data around the model edges Nearest Neighbour estimation was used.

The Mineral Resource was estimated using four passes in the search strategy. The results of the first two passes are nominally equated to blocks classified as Measured and Indicated, with the latter two passes equating to blocks classified as Inferred. The resources were defined across the salar outline and extension around E26, defined over different depths, reflecting drilling density and confidence. Future drilling on the salar may bring additional Mineral Resources into the Indicated and Measured classification.

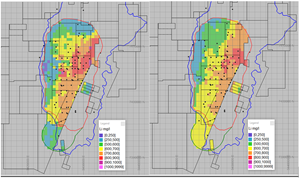

Figure 6: Lithium grades (mg/L) at 100 m (left) and 250 m below surface (right.)

https://www.globenewswire.com/NewsRoom/AttachmentNg/d066869c-a33c-4487-8620-aa6578dd8a23

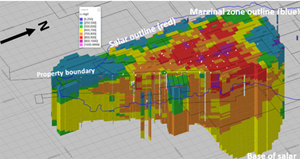

Figure 7: Resource blocks in lithium mg/l, showing the salar edge (red), alluvial zone (green) in the south and the muddy marginal zone outline (between red and blue outlines).

https://www.globenewswire.com/NewsRoom/AttachmentNg/0f61b68a-de50-4f54-b482-6514fd58dae0

Mineral Resources classification

Measured Mineral Resources

The Measured classification is based on reliable geological correlation between drill holes, which show gradual changes in lithology laterally and with depth. Measured Resources were previously defined to cover the entire salar area to 200 m depth, as exploration drilling was previously conducted across the salar area to 54 m and 200 m depth. The deeper extension of the Measured Resource in this estimate is defined based on the drill hole depth in the pumping field, with the resource to 650 m depth in the east of the salar and 450 m deep in the west, where drill holes are shallower. Measured Resources are defined to 350 m depth around holes drilled in the Maria Victoria property, in the north of Olaroz, extending below the 200 m depth defined elsewhere in the north of the salar.

Classification is supported by ongoing extraction by pumping of brine from production wells installed to 200 m since 2013, 300 m since 2014 and 650 m since 2021, with 1 km spaced production wells and a drilling density of approximately 1 hole per 2 km2.

Indicated Mineral Resources

Geological continuity established by deeper drilling below 200 m, geophysical logging of holes, and gradual changes in lithium concentration provide the basis for classifying the brine below 200 and 350 metres below surface in the north of the salar (with lesser drilling density) and south of the salar around hole E26, to the base of the salar in that area as Indicated. Mineral Resources below this depth are defined as Inferred.

Laboratory porosity samples are relatively limited below 200 metres, however similar sediment intervals are present above 200 metres at Olaroz, where porosity characteristics have been established from hundreds of laboratory analyses. Extensive porosity samples from similar sediments are also available from the Allkem Cauchari properties. Ongoing extraction by pumping of brine from wells up to 450 metres deep since 2014 and from 650 metres depth for up to 3 years, provides confidence as to the extractability of brine from the resource to this depth.

BMR porosity data was collected below 200 metres depth, providing extensive porosity data in the Stage 2 holes. Future drilling below 200 metres provides the opportunity to upgrade Indicated Mineral Resources to Measured Mineral Resources status.

Inferred Mineral Resources

The Inferred Mineral Resource is defined between 200 or 350 metres and 650 metres in the north of the salar and below 650 metres to the base of the basin. The base of the basin is defined by the gravity geophysical survey, with areas significantly deeper than 650 m defined. There are currently 19 production wells installed to 350 metres or below, with production wells for Olaroz Stage 2 installed between 400 and 751 metres deep between the existing northern and southern wellfields. The deep hole drilled in the north of the salar confirms locally the salar sediments extend to below 1400 metres depth. Drilling has not intersected the base of the salar sediments, where the geophysical estimated basement depth has been reached, suggesting the basin may be deeper than estimated from the gravity survey. Limited brine samples were collected in this deep hole.

Taking account of the distribution of brine grade and porosity to date (as determined by BMR geophysics) there is a sufficient level of confidence to classify the Mineral Resources extending to the bottom of the basin as Inferred Mineral Resources. It is likely that additional drilling could convert these to a higher confidence Mineral Resource classification.

Mineral Resource classification table and cut-off grade

Since publication of the updated Mineral Resource on 27 March 2023, Allkem has undertaken a company-wide review of Mineral Resources. This has led to the reclassification of a large portion of the Olaroz Indicated Mineral Resources to Measured Mineral Resources.

The Olaroz brine project is a very large salar which hosts lithium dissolved in hypersaline brine present in pore spaces between sediment grains. The brine mineralisation in the resource covers an area of 147.9 km2, within a larger area also known to contain lithium-mineralised brine.

The lithium concentration is highly homogeneous compared to most mineral deposits, as the lithium concentration process results in a relatively homogeneous brine concentration. The lithium concentration varies slowly laterally and vertically across the salar. There is no internal waste (uneconomic lithium concentrations) within the Mineral Resource. Stage 1 and Stage 2 of the project have been developed with conventional evaporation pond technology. Future additional developments may utilise direct extraction technologies.

The Mineral Resource was previously stated with no cut-off grade, considering its large homogeneous nature and location almost entirely on the Salar. As an outcome of internal peer review the Mineral Resource is now stated at a lithium cut-off grade of 300 mg/L, applied based on a breakeven cut-off grade for a projected LCE price of US$20,000 per tonne) over the entirety of the life of mine (there are no areas within the resource below this).

BRINE EXTRACTION AND PROCESSING

A groundwater model has been developed for Allkem by Napa consultants of Barcelona, Spain, covering the Olaroz and Cauchari basins. The model was developed in FeFlow groundwater modelling software, based on the exploration and production holes drilled to date and calibrated with the pre-production water levels and the results of production pumping.

The Steady State model was calibrated to 49 wells and the Transient model was calibrated to 32 wells with 12,921 data points from production pumping since 2013, providing extensive information on brine levels and response to pumping. Geochemical data was available from 107 monitoring points having 33,640 geochemical data points. The model was calibrated in a steady state configuration and also calibrated with the results of pumping from the period from 2013 to 2018 in a Transient mode. The effects of industrial water extraction from the existing water source in the Archibarca area, south of the plant, was also simulated in the evaluation.

The model was subsequently used for a number of model simulations of future production scenarios, including Stage 2 development, with coincident pumping and operation of the adjacent Exar project in Cauchari-Olaroz, to simulate the results of combined pumping and long term extraction of brine from the large brine body present in the salt lake.

The model will be used to evaluate different scenarios for the development of Stage 3 of the project, and will be updated to incorporate results from additional drilling in the Olaroz basin, particularly in the north of the Salar and south of the ponds and plant, where there is little current information available. With this information the model will be used to simulate future combined production in the basin and to develop an Ore Reserve estimation for the different stages of the project. Brine is extracted from the host sediments from wells at different depths, depending on the age of the wells. There is no mining of the sediments. All extraction of lithium is via brine.

Audits and reviews

An independent assessment of the groundwater model that will be used to derive Ore Reserves has been undertaken and observations and recommendations are being reviewed and implemented.

Operations and Stage 2 Status

The Olaroz project was subject to an initial definitive feasibility study in 2011 with engineering company SKM which was the basis for Stage 1 project design and construction. A subsequent study was undertaken to support the development of Stage 2 of the project, the results of which were published in April 2022 in a JORC compliant announcement and NI 43-101 technical report. The Stage 2 project has now been constructed, achieved first wet production in July 2023, and is in the commissioning stage with operations ramp-up starting H2 CY23.

The Olaroz project borefield and ponds have been operating successfully from 2013 and site based lithium processing and sale of lithium carbonate product from 2015 as part of the Stage 1 project development. The Stage 2 development is designed with a substantial increase in the evaporation pond area with the addition of 9 km2 of new ponds. A second processing plant has been built to increase annual production capacity to 42,500 ktpa LCE from the combined Stages 1 and 2. The new plant design is based upon the original Stage 1 plant but with improved equipment selection and processing strategy based on that experience.

Mining Factors

Mining is undertaken by the installation of large diameter (12 inch installed casing) wells into the salt lake sediments. Once installed and developed the wells are pumped to provide a continuous supply of brine to the project evaporation ponds. The wells provide an average lithium concentration that is derived from the sediments where production wells are installed.

Only a portion of the project resource can be extracted, due to the limitations of extraction by widely spaced wells. This amount was simulated in the groundwater model which will be the basis for the future project Ore Reserve, which will take account of salar’s environmental factors during extraction. The extraction from wells was simulated using calibration data from actual pumping operations since 2013, providing an extensive dataset for model calibration and prediction.

Extraction using bores is the appropriate extraction choice in salars, as the lithium is dissolved in brine (fluid) and mining of unconsolidated sediments is not contemplated. There are no minimum mining widths, as brine mining is not a selective mining method.

Geotechnical parametres for brine extraction are different to hard rock mining, and consider issues such as compaction and settlement of sediments over time as brine is extracted.

Inferred Mineral Resources are present beneath and laterally to the volumes of Measured and Indicated Mineral Resources. The Inferred Mineral Resources are not included in current mining studies but are considered a possible source of future brine extraction, when further drilling is completed.

Brine mining requires the provision of electricity and pipelines to the sites of wells from which brine is extracted. The pipelines pump brine to centralised collection ponds, from where it is pumped to the evaporation pond network. The brine is subject to the addition of lime in the evaporation ponds. Pumps are required to move brine between ponds and pump brine into the plant, where lithium carbonate product is produced. A gas pipeline provides the energy source for onsite electricity and heat generation.

Brine is liquid and flows in response to operation of pumps installed in wells, with pumping inducing radial flow towards the well and extraction of brine to evaporation ponds. The location of some of the Stage 2 production wells in proximity to the eastern boundary of the Olaroz SDJ properties will result in a portion of the brine from these wells being extracted from adjacent properties. This is a small portion of the overall brine extraction.

The lithium concentration in brine is forecast based on the groundwater flow and transport model. This predicts a minor decline in the lithium concentration over time, from 650 mg/L in 2023 to an overall concentration of approximately 570 mg/l in 2053.

Metallurgical factors

The metallurgical process utilised for the production of lithium carbonate is based on solar evaporation of brine prior to reacting lithium with soda ash in the plant to produce lithium carbonate. In this way much of the energy required for the process is provided naturally by the sun. Lithium remains soluble in the brine, and other elements precipitate in response to their increasing concentration and saturation in the brine. Lime is added to the ponds to facilitate the precipitation of magnesium from the brine. Although more recent direct extraction processing techniques are now more widely available pond evaporation provides a cost-effective and low risk processing method for Olaroz brine.

The metallurgical process is based on the well-established Silver Peak process, which was adapted for use at the Olaroz project. The project has been producing lithium using the Olaroz process since 2015, with optimisation of the process undertaken during this period.

Extensive test work was undertaken on the Olaroz brine prior to finalisation of the process and development of the project. Deleterious elements were characterised during the exploration of the project and evaluated extensively during the process development. Pilot scale testing was undertaken at the site in real environmental conditions. The actual processing plant has now been operating since 2015.

Lithium Carbonate is sold as both technical (>99.3% Li) and battery grade (>99.5% Li) product, depending on the concentration of impurities. The project produces both grades of product.

The Olaroz Stage 2 process plant has been designed primarily based on the experience gained from 5 years of operating development and data analysis from the Stage 1 process plant. Some equipment specific testing was also conducted, mostly on new solid liquid separation steps in the polishing area.

The Olaroz 2 plant is similar in its general process flowsheet and chemistry to the Stage 1 plant, however it has been designed to provide higher quality technical grade product and improved recovery in the primary carbonation circuit. This is achieved by:

- Washing of solid precipitates in the polishing circuit to minimise lithium loss

- Inclusion of improved ultra-fine filtration technology in the polishing circuit which will contribute to product quality

- Removal of trace Ca and Mg by ion exchange (“IX”) processing of carbonation reactor feed which will contribute to product quality and an anticipated improvement from technical to battery grade

- Improved control of washing and filtration of final product using air blown plate and frame filters, also contributing to improved quality by minimizing entrained impurities in the cake moisture

- Improved process control by enhanced instrumentation and increased process buffer storage

It should be notes that Stage 2 does not include a purification circuit as installed in Stage 1.

A gas fired rotary drying kiln has been used in the Olaroz Stage 2 drying plant, along with additional micronising capacity. A new soda ash bag storage area and mixing plant with the capability to convert to bulk delivery has been designed. Additional raw water wells in the Archibarca alluvial field and downstream reverse osmosis plant capacity are provided to meet the increased clean water requirements. Extended water supply rights have been obtained in the northern Rosario River alluvial sediments. The required increase in power generating capacity is provided by expansion of the stage 1 gas fired generators and additional boiler capacity for solution heating.

INFRASTRUCTURE

The project is well served by infrastructure, being located adjacent to a paved international highway between Argentina and Chile that leads to major import and export ports in Northern Chile.

The project is supplied by a spur line from a gas pipeline which passes to the north of the project. Electricity and heat are generated on site for the project process and camp.

Water for industrial processes is obtained from groundwater that is treated by reverse osmosis.

Accommodation is provided by purpose-built accommodation at the project, with additional accommodation provided in nearby villages and towns.

FINANCIAL PERFORMANCE

Olaroz Stage 2 reached substantial Mechanical Completion in June 2023 with first wet production achieved in July 2023.

Capital investment for Olaroz Project Stage 2, including equipment, materials, indirect costs, and contingencies and pre-commissioning activities during the construction period was estimated to be US$425 million, excluding VAT and working capital.

The operating costs estimate for Olaroz was updated by Allkem’s management team. Most of the operating costs are based on labour and consumables which are currently in use at the operation.

Table 3 provides a summary of the estimated cost by category for a nominal year of operation.

Table 3: Stage 1 and 2 - Summary of Operating Cost

| Operating Cost | Units | Total | |

| Reagents | US$/t LCE | 2,280 | |

| Labour | US$/t LCE | 816 | |

| Energy | US$/t LCE | 98 | |

| General and Administration | US$/t LCE | 687 | |

| Consumables and Materials | US$/t LCE | 240 | |

| Transport and Port | US$/t LCE | 28 | |

| TOTAL OPERATING COST | US$/ t LCE | 4,149 | |

| Minor discrepancies may occur due to rounding | |||

Lithium carbonate price forecast

Lithium has diverse applications including ceramic glazes, enamels, lubricating greases, and as a catalyst. Demand in traditional sectors grew by approximately 4% CAGR from 2020 to 2022. Dominating lithium usage is in rechargeable batteries, which accounted for 80% in 2022, with 58% attributed to automotive applications. Industry consultant, Wood Mackenzie (“Woodmac") estimates growth in the lithium market of 11% CAGR between 2023-2033 for total lithium demand, 13% for automotive, and 7% for other applications.

Historical underinvestment and strong EV demand have created a supply deficit, influencing prices and investment in additional supply. Market balance remains uncertain due to project delays and cost overruns. The market is forecast to be in deficit in 2024, have a fragile surplus in 2025, and a sustained deficit from 2033.

Prices have fluctuated in 2022-2023, in response to EV sales, Chinese production, and supply chain destocking trends. Woodmac notes that battery grade carbonate prices are linked to demand growth for LFP cathode batteries and are expected to decline but rebound by 2031. Lithium Hydroxide’s growth supports a strong demand outlook, with long-term prices between US$25,000 and US$35,000 per tonne (real US$ 2023 terms).

PROJECT ECONOMICS

An economic analysis was developed using the discounted cash flow method and was based on the data and assumptions for capital and operating costs detailed in this report for brine extraction, processing and associated infrastructure. The evaluation was undertaken on a 100% equity basis.

The lithium price used in the economic analysis is weighted on the basis of the proportion of the various products produced. The basis of forecast lithium carbonate pricing was provided by Woodmac who expect prices to settle between US$26,000/ t and US$31,000/ t (real US$ 2023 terms) over the longer term.

There is a 3 percent mine mouth (boca de mina) royalty on the value of production to the provincial Jujuy government, considered the value of the product after the deduction of the costs of extraction, processing and transportation. There is an export duty of 4.5% on the FOB price, as regulated by Argentinian Government Decree Nr. 1060/20.

Olaroz Stage 1 and 2 production is expected to reach nominal capacity of 42,500 metric tonnes per year of lithium carbonate for an estimated operational life of approximately 32 years. This would result in the production of approximately 543,030 dry metric tonnes (“dmt”) of saleable lithium carbonate. When considering both Stage 1 and 2, the total saleable product is estimated to be 1,310,670 dmt of lithium carbonate for the LOM.

The saleable product for Stage 2 is expected to be of technical grade (>99.3% Li). However, it's important to note that Stage 1 includes both Technical and Battery Grade (>99.5% Li) lithium carbonate.

The key assumptions and results of the economic evaluation are displayed in Table 4 below.

Table 4: Key assumptions utilised in the project economics

| Assumption | Units | Stage 1 and 2 |

| Project Life Estimate | Years | 32 |

| Discount Rate (real) | % | 10 |

| Provincial Royalties 1,2 | % of LOM net revenue | 3.0 |

| Corporate Tax2 | % | 35 |

| Annual Production3 | tonnes LCE | 42,500 |

| CAPEX (Olaroz Stage 2) | US$M | 425 |

| Operating Cost | US$/tonne LCE | 4,149 |

| Average Selling Price4 | FOB US$/tonne LCE | 24,798 |

|

1 Provincial royalty agreement at 3.0%, export duties, incentives and other taxes are not shown. JEMSE, the Jujuy provincial mining body, holds an 8.5% interest in SDJ 2 There is a risk that the Argentina Government may, from time to time, adjust corporate tax rates, export duties and incentives that could impact the Project economics 3 Based on 100% technical grade lithium carbonate coming out of Olaroz Stage 2 4 Based on price forecast provided from Wood Mackenzie and targeted production grades stated in Footnote 3 above | ||

The project economics of Olaroz Stage 1 and 2 demonstrates strong results, with substantial net present values and robust projected revenue and operating cash flow figures.

Pre-Tax NPV@10% is estimated to be US$7,012 million. Post-Tax NPV@10% is estimated to be US$4,562 million.

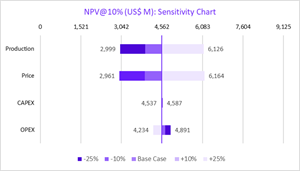

Sensitivity Analysis

As displayed in Table 4 above, the Olaroz operations update for Stage 1 and 2 demonstrates strong financial outcomes with a post-tax NPV at 10% discount rate of US$4,652 million. Figure 8 analyses the impact on post-tax NPV when pricing, operating cash costs and development CAPEX fluctuate between +/- 25 %.

Figure 8: NPV Sensitivity Analysis

https://www.globenewswire.com/NewsRoom/AttachmentNg/38ae641b-15d6-4e22-babf-7a8d164122aa

Environmental

The Environmental Monitoring and Follow-up Plan (“PMSA”) of SDJ contains the procedures and methodologies to evaluate the environmental components of the project area and to measure and monitor their variations during operation. Olaroz Stage 2 is permitted under 2016 and 2018 authorisations, with additional authorisations from March 2021.

Environmental Monitoring aims to obtain data on periodic and seasonal environmental parametres, running quarterly campaigns, in the months of February, May, August and November. The objectives are to verify that environment conditions in the area of influence by the operation remain unchanged or that changes produced are within the approved permissible limits as part of the project operations.

This work includes extensive studies of flora, fauna, hydrogeology, hydrology, climate, air quality, noise, limnology, landscape characteristics and ecosystem characterisation. This is supported by social economic and cultural studies, surveys and support programs.

SDJ has received the relevant permissions from 2009 through 2021 for the Olaroz Project development and operating activities from provincial and federal agencies, such as the provincial Jujuy Mining Directorate and the UGAMP scientific committee of Jujuy (which reviews lithium project developments), provincial water resource authority and environmental authorities.

The project is located in the Olaroz Cauchari Fauna and Flora Reserve (La Reserva de Fauna y Flora Olaroz-Cauchari). The reserve was created in 1981, under provincial law 3820. The reserve is a multi-use area that allows for agricultural and mining activities and scientific investigation programs. The operation of the Olaroz project is consistent with the multi-use reserve status.

Social and Community Relations

SDJ has been very actively involved in community relations since the properties were acquired in 2008. Although there is minimal habitation in the area of the Salar, SDJ has consulted extensively with the local aboriginal communities.

SDJ has agreements with communities in the territory where the Olaroz brine operation is developed, which are the communities of Olaroz Chico and El Toro (the northern area around the Rosario River) and provides assistance to the local community, by providing services to community members and employing a significant number of people from the surrounding communities in the current operations.

As part of the SDJ community and social performance policy, SDJ has a commitment to six communities to provide an Internet connection and a commitment to nine communities so that every two years SDJ makes an investment in the construction of infrastructure for community use. Ten communities in the surrounding area are beneficiaries of the Community Relations Plan programs. Olaroz Stage 2 will provide new employment opportunities and investment in the region, which is expected to be positive. Currently, 40% of the project workforce is from surrounding towns and 75% is sourced from within the province of Jujuy.

This release was authorised by Mr Martin Perez de Solay, CEO and Managing Director of Allkem Limited.

|

Allkem Limited ABN 31 112 589 910 Level 35, 71 Eagle St Brisbane, QLD 4000 |

Investor Relations & Media Enquiries Andrew Barber +61 418 783 701 Andrew.barber@allkem.co |

Connect info@allkem.co +61 7 3064 3600 www.allkem.co |

|

IMPORTANT NOTICES

This investor ASX/TSX release (“Release”) has been prepared by Allkem Limited (ACN 112 589 910) (the “Company” or “Allkem”). It contains general information about the Company as at the date of this Release. The information in this Release should not be considered to be comprehensive or to comprise all of the material which a shareholder or potential investor in the Company may require in order to determine whether to deal in Shares of Allkem. The information in this Release is of a general nature only and does not purport to be complete. It should be read in conjunction with the Company’s periodic and continuous disclosure announcements which are available at allkem.co and with the Australian Securities Exchange (“ASX”) announcements, which are available at www.asx.com.au.

This Release does not take into account the financial situation, investment objectives, tax situation or particular needs of any person and nothing contained in this Release constitutes investment, legal, tax, accounting or other advice, nor does it contain all the information which would be required in a disclosure document or prospectus prepared in accordance with the requirements of the Corporations Act 2001 (Cth) (“Corporations Act”). Readers or recipients of this Release should, before making any decisions in relation to their investment or potential investment in the Company, consider the appropriateness of the information having regard to their own individual investment objectives and financial situation and seek their own professional investment, legal, taxation and accounting advice appropriate to their particular circumstances.

This Release does not constitute or form part of any offer, invitation, solicitation or recommendation to acquire, purchase, subscribe for, sell or otherwise dispose of, or issue, any Shares or any other financial product. Further, this Release does not constitute financial product, investment advice (nor tax, accounting or legal advice) or recommendation, nor shall it or any part of it or the fact of its distribution form the basis of, or be relied on in connection with, any contract or investment decision.

The distribution of this Release in other jurisdictions outside Australia may also be restricted by law and any restrictions should be observed. Any failure to comply with such restrictions may constitute a violation of applicable securities laws.

Past performance information given in this Release is given for illustrative purposes only and should not be relied upon as (and is not) an indication of future performance.

Forward Looking Statements

Forward-looking statements are based on current expectations and beliefs and, by their nature, are subject to a number of known and unknown risks and uncertainties that could cause the actual results, performances and achievements to differ materially from any expected future results, performances or achievements expressed or implied by such forward-looking statements, including but not limited to, the risk of further changes in government regulations, policies or legislation; risks that further funding may be required, but unavailable, for the ongoing development of the Company’s projects; fluctuations or decreases in commodity prices; uncertainty in the estimation, economic viability, recoverability and processing of mineral resources; risks associated with development of the Company Projects; unexpected capital or operating cost increases; uncertainty of meeting anticipated program milestones at the Company’s Projects; risks associated with investment in publicly listed companies, such as the Company; and risks associated with general economic conditions.

Subject to any continuing obligation under applicable law or relevant listing rules of the ASX, the Company disclaims any obligation or undertaking to disseminate any updates or revisions to any forward-looking statements in this Release to reflect any change in expectations in relation to any forward-looking statements or any change in events, conditions or circumstances on which any such statements are based. Nothing in this Release shall under any circumstances (including by reason of this Release remaining available and not being superseded or replaced by any other Release or publication with respect to the subject matter of this Release), create an implication that there has been no change in the affairs of the Company since the date of this Release.

Technical Information and Competent Persons’ Statements

The information in this report that relates to Olaroz’s Exploration Results and Mineral Resources is based on information compiled by Mr. Murray Brooker who is a Member of the Australian Institute of Geoscientists (AIG), a Registered Professional Geoscientist in Australia (RPGeo) and a member of the International Association of Hydrogeologists (IAH) and Michael Gunn, BAppSc. (Metallurgy)(Gunn Metallurgy) is a Chartered Professional Fellow of the Australasian Institute of Mining and Metallurgy (FAusIMM), both of whom are recognised as Competent Persons by a ‘Recognised Professional Organisation’ (RPO) included in a list posted on the ASX website from time to time. Murray Brooker an employee of Hydrominex Geoscience Pty Ltd and Michael Gunn an employee of Gunn Metallurgy have sufficient experience that is relevant to the style of mineralisation and type of deposit under consideration and to the activity being undertaken to qualify as a Competent Person as defined in the 2012 Edition of the ‘Australasian Code for Reporting of Exploration Results, Mineral Resources and Ore Reserves’. Murray Brooker and Michael Gunn consent to the inclusion in this announcement of the matters based on their information in the form and context in which it appears.

The scientific and technical information contained in this announcement has been reviewed and approved by, Murray Brooker (Hydrominex Geoscience Pty Ltd), as it relates to geology, modelling, and Mineral Resource estimates; Michael Gunn, BSc. Chemical Engineering (Gunn Metallurgy), as it relates to processing, facilities, infrastructure, project economics, capital and operating cost estimates. The scientific and technical information contained in this release will be supported by a technical report to be prepared in accordance with National Instrument 43-101 – Standards for Disclosure for Mineral Projects. The Technical Report will be filed within 45 days of this release and will be available for review under the Company’s profile on SEDAR at www.sedar.com.

Not for release or distribution in the United States

This announcement has been prepared for publication in Australia and may not be released to U.S. wire services or distributed in the United States. This announcement does not constitute an offer to sell, or a solicitation of an offer to buy, securities in the United States or any other jurisdiction, and neither this announcement or anything attached to this announcement shall form the basis of any contract or commitment. Any securities described in this announcement have not been, and will not be, registered under the U.S. Securities Act of 1933 and may not be offered or sold in the United States except in transactions registered under the U.S. Securities Act of 1933 or exempt from, or not subject to, the registration of the U.S. Securities Act of 1933 and applicable U.S. state securities laws.

Appendices

The following appendices provide a summary of drill hole coordinates and average lithium concentrations for Stage 2 production wells (E-series holes) and Stage 1 production wells (P and PP-series holes).The appendices also include the JORC Table 1 for the announcement.

APPENDIX A: DRILL HOLE COLLARS AND LITHIUM CONCENTRATION

*Average well flows from 12 January 2017 to 31 January 2023

APPENDIX B

JORC Table 1 – Section 1 Sampling Techniques and Data related to Olaroz Stage 2 expansion drilling (Criteria in this section apply to all succeeding sections.)

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques |

|

|

| Drilling techniques |

|

|

| Drill sample recovery |

|

|

| Logging |

|

|

| Sub-sampling techniques and sample preparation |

|

|

| Quality of assay data and laboratory tests |

|

|

| Verification of sampling and assaying |

|

|

| Location of data points |

|

|

| Data spacing and distribution |

|

|

| Orientation of data in relation to geological structure |

|

|

| Sample security |

|

|

| Audits or reviews |

|

|

Section 2 - Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section.)

| Criteria | JORC Code explanation | Commentary |

| Mineral tenement and land tenure status |

|

|

| Exploration done by other parties |

|

|

| Geology |

|

|

| Drill hole Information |

|

|

| Data aggregation methods |

|

|

| Relationship between mineralisation widths and intercept lengths |

|

|

| Diagrams |

|

|

| Balanced reporting |

|

|

| Other substantive exploration data |

|

|

| Further work |

|

|

Section 3 Estimation and Reporting of Mineral Resources

| Criteria | JORC Code explanation | Commentary |

| Database integrity |

|

|

| Site visits |

|

|

| Geological interpretation |

|

|

| Dimensions |

|

|

| Estimation and modelling techniques |

|

|

| Moisture |

|

|

| Cut-off parameters |

|

|

| Mining factors or assumptions |

|

|

| Metallurgical factors or assumptions |

|

|

| Environmental factors or assumptions |

|

|

| Bulk density |

|

|

| Classification |

|

|

| Audits or reviews |

|

|

| Discussion of relative accuracy/ confidence |

|

|

1 Includes SDJ properties (AKE 66.5%) and other 100% AKE owned properties