Becoming Reliable Precision Cast Iron Surface Plate Manufacturer with CE Certification - ZHHIMG

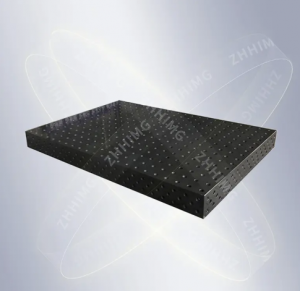

In this highly specialized field, Zhonghui Intelligent Manufacturing (Jinan) Co., Ltd. (ZHHIMG®) has firmly established its position as a Reliable Precision Cast Iron Surface Plate Manufacturer, now recognized globally with the achievement of the vital CE certification for the European market. ZHHIMG’s success is built upon a legacy of dedicated expertise in structural stability and geometric mastery, ensuring its products meet the most stringent demands for foundational accuracy.

Industry Outlook: The Global Imperative for Traceable Dimensional Stability

The acceleration of industrial technology, driven by automation and the need for micron-level precision, has dramatically amplified the market requirement for high-quality, traceable reference surfaces. The performance of advanced manufacturing tools, particularly multi-axis machine tools and sophisticated Coordinate Measuring Machines (CMMs), is fundamentally limited by the stability of the base they rest upon.

Key Trends in Metrology and Foundational Standards

The market for precision reference equipment is currently defined by three critical trends:

Demand for Large-Format and Specialized Cast Iron Tooling: The sheer scale of components in modern industries—such as large aerospace tooling jigs, shipbuilding assemblies, and components for new energy infrastructure—necessitates reference plates that are massive, yet maintain micron-level flatness. This drives the market toward manufacturers capable of producing exceptionally large cast iron bases, often featuring specialized geometries like T-slots, U-slots, and threaded inserts, converting the passive surface into an active tooling platform.

Increased Focus on Certification and Global Compliance (EEAT): As supply chains globalize, end-users demand verifiable assurance. Compliance with international standards, such as ISO 8512-2 and DIN 876, is the baseline. The addition of the CE Mark validates ZHHIMG’s conformity with essential European health, safety, and environmental protection standards, significantly enhancing the manufacturer's expertise, authoritativeness, and trustworthiness on the global stage.

Mastery of Material Stress and Long-Term Stability: The longevity and reliability of a cast iron surface plate are determined by its ability to resist subtle, time-dependent deformation ("creep"). This requires manufacturers to possess advanced knowledge of metallurgy and thermal engineering. The meticulous application of specialized stress-relieving techniques, including thermal cycling and natural aging, is crucial to guarantee that the plate retains its certified accuracy over decades of heavy use.

The market rewards manufacturers who can scale their production while rigorously upholding these standards of stability and certification.

ZHHIMG’s Manufacturing Excellence and Technical Control

ZHHIMG's success as a precision surface plate manufacturer is predicated on its comprehensive technical control over the entire production process, from the initial melt to the final calibration. Based in Shandong Province, the company operates two advanced manufacturing facilities equipped to handle both high-volume standardized production and complex custom projects.

The Precision Production Cycle

ZHHIMG’s core technical advantage lies in its disciplined, multi-stage production cycle for its Precision Cast Iron Surface Plates:

Premium Material and Casting: Utilizing high-grade, fine-grained gray cast iron (typically meeting or exceeding HT250 specifications). The material is selected specifically for its high graphite content, which imparts the superior internal damping necessary to absorb machinery vibrations, a critical factor for CMM bases.

Controlled Stress Relief: Following the casting and initial rough machining, plates undergo meticulous stress-relieving procedures. This involves controlled thermal treatments and extended periods of natural aging to eliminate internal stresses. This process is non-negotiable for achieving the long-term, verifiable dimensional stability that defines a high-quality inspection surface.

Advanced Machining and Final Hand Scraping: After initial CNC machining establishes the basic geometry, the final, supreme level of accuracy is achieved through the traditional, labor-intensive method of hand scraping. This skilled craftsmanship ensures the precise distribution of bearing points across the surface, critical for achieving surface flatness up to the most demanding 00 Grade (approximately 1 micrometer flatness tolerance).

Verified Product Advantage: Certified Precision Cast Iron Surface Plates

ZHHIMG’s product line is robust and tailored to specific precision needs across various industries, ensuring high-reliability performance and strict adherence to global standards.

Grade Compliance: Plates are manufactured to strict adherence with international standards, including DIN 876 and relevant JIS standards, ensuring global compatibility. The range spans from Inspection Grade Plates (Grade 00 and 0) for dedicated metrology labs and CMM applications, to Workshop Grade Plates (Grade 1 and 2) designed for robust daily use on the factory floor.

Dimensional Accuracy Verification: The final accuracy of every surface plate is rigorously verified using sophisticated metrology equipment, including high-accuracy autocollimators and laser interferometers. This provides indisputable technical data proving the plate's geometric compliance before shipment. The precision grinding capability consistently achieves flatness and parallelism accuracy below 0.003 mm.

Customization and Functionality: ZHHIMG excels in manufacturing custom specifications, including large-scale tooling plates and surfaces integrated with complex features such as T-slots, parallel V-slots, and strategically positioned threaded inserts. This allows the plate to transition from a passive reference tool to an active, precise tooling fixture base.

The acquisition of the CE certification formally validates ZHHIMG's entire operational integrity against European safety, health, and environmental benchmarks. This certification is a strategic asset that streamlines market entry for clients operating in regulated environments, reinforcing ZHHIMG’s identity as a manufacturer whose quality assurance is internationally recognized and verified.

Conclusion: Foundations for Future Accuracy

The future of high-precision manufacturing demands foundational stability that is both technically verified and globally certified. ZHHIMG’s singular focus on mastering the metallurgical and geometric complexities of cast iron manufacturing solidifies its role as a fundamental enabler of technological advancement. By delivering verified, high-stability reference equipment—underpinned by disciplined manufacturing processes, meticulous hand scraping, and the authoritative CE Certification—ZHHIMG provides the essential, reliable foundation upon which the world's most demanding manufacturing processes can confidently build their accuracy.

For more information on ZHHIMG’s precision cast iron surface plates and metal fabrication capabilities, please visit the official website: https://www.zhhimg.com/

Zhonghui inteligent Manufacturing (Jinan) Group Co., Ltd.

Zhonghui inteligent Manufacturing (Jinan) Group Co., Ltd.

+ +86 199 6999 1659

info@zhhimg.com

Visit us on social media:

LinkedIn

Instagram

Facebook

YouTube

X

Other

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.